1. Introduction

In most regions of the developed world, the building stock has already started to age considerably. Within the European Union for example, 80% of the buildings were built before the 90's, 40% before the 60's, with a third of buildings over 50 years old [1]. The impact of the old building stock on the environment is huge as buildings are responsible for 36% of the CO2 emissions and 40% of the total energy consumption in the EU. For this reason, the European Green Deal [2] emphasizes the need for the EU and its Member States to engage in a ‘Renovation wave’ of their buildings [3] and a New European Bauhaus initiative. At the same time, the strong recent earthquakes (e.g. in Southern Europe) revealed also the poor seismic resistance of the of old buildings, many of which collapsed under seismic excitations resulting in significant economic losses, severe injuries and loss of human lives. As a result it was suggested within the Energy Performance of Buildings Directive [4] that also seismic risks should be addressed by Member States when planning long-term renovation strategies of buildings. Therefore, the lifetime extension of existing buildings should also include their seismic upgrading for the seismic-prone regions.

The introduction of modern seismic design standards (e.g. [5]) has addressed mainly the seismic safety of new buildings. At the same time, the last couple of decades, the scientific community has focused more on the seismic risk associated with the existing buildings and proposed, developed and experimentally tested various seismic retrofitting methods, with the aim of transferring these techniques from the laboratories to the real engineering practice. Moreover, seismic standards (e.g. [6]) and guidelines (e.g. [7], [8]]) for the retrofitting of existing structures were published relatively recently. Their application is not yet obligatory though, except for specific cases.

Within this scope, the present paper aims at providing a thorough review of the seismic upgrading techniques, which target reinforced concrete (RC) buildings, as the latter constitute the largest portion of the existing building stock. A briefer overview for all building types was recently given in [9]. Seismic upgrading techniques can be divided in two major categories, depending on the way they “treat” the structure. At first, there are the ones that operate at the element level (Local measures) and then those that operate on the structure as a whole (Global measures). Obviously, when it comes to upgrading an actual building, various techniques can and might need to be combined, addressing its specific characteristics, so that a cost-effective strengthening scheme can be provided. Depending on their age as well as the materials employed in each technique, the seismic intervention techniques can also be further divided to conventional and novel ones.

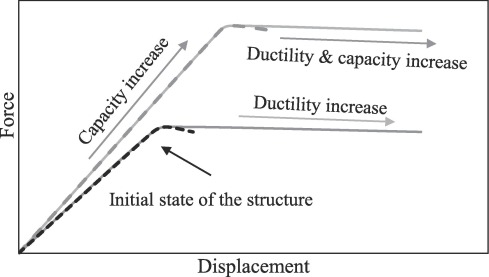

Fig. 1 shows the goals at which a seismic retrofitting scheme might aim. When only the ductility of a structure needs to be improved, then local measures are typically sufficient and normally do not affect the structure’s strength and stiffness, or they affect it marginally. However, if the capacity also needs to be increased, global measures will most likely have to be employed, as achieving a much higher lateral load capacity in a structure via local measures alone would be an uneconomical option. Lastly, in cases that both the capacity and ductility of a structure are in need of improvement, then a combination of global and local measures should be employed. It is noted that in the context of this work, the terms “capacity” and “strength” are used interchangeably.

Fig. 1

Fig. 1Apart from increasing a building’s lateral strength, there is also the alternative of decreasing the earthquake-induced forces, which can be achieved by reducing the mass and/or reducing the lateral stiffness of the structure. Mass reduction can be realized through the use of lighter partition walls, floor removal etc., while stiffness reduction is achieved via the employment of base isolators and energy dissipation systems, while certain energy dissipation systems (e.g. Buckling-restrained braces, see Section 3.1.1.3) may also add stiffness. Fig. 2 outlines the main categories of seismic upgrading techniques targeting RC buildings, whereas Table 1 summarizes the most common measures together with the properties they affect. Specific techniques will be thoroughly described in the next sections of this paper.

Fig. 2

Fig. 2Table 1. Effect of local and global retrofit measures on building properties (partially based on [98]).

| Technique | Strength | Stiffness | Ductility | Irregularity | Force demand | Deformation demand | |

|---|---|---|---|---|---|---|---|

| Local measures | RC/mortar jacketing | + | + | + | – | + | |

| Steel jacketing | + | + | |||||

| FRP/TRM jacketing | + | + | |||||

| Hybrid jackets | + | + | |||||

| Global measures | Bracing systems | + | + | + | – | + | |

| Shear walls | + | + | + | – | + | ||

| Infills | + | + | + | – | + | ||

| Mass reduction | + | + | – | ||||

| Seismic isolation | – | + | + | + | |||

| Energy dissipation systems | +/- | + |

2. Local measures

The local upgrading techniques comprise measures applied to specific structural elements of a building, in order to enhance their mechanical characteristics. The general idea is to add some sort of external reinforcement to the existing beam/column/joint member and that way increase its flexural and/or shear capacity as well as its ductility. Traditional techniques make use of conventional materials like concrete and structural steel, whilst novel ones employ more innovative materials like Fiber Reinforced Polymers (FRP), Textile Reinforced Mortars (TRM) etc. In the following sections, both conventional and novel techniques will be described, putting more emphasis on the latter.

2.1. RC/mortar jacketing

The first and probably most traditional technique of seismic upgrading of RC members, is that of constructing an RC jacket around the initial element (Fig. 3), thus enlarging its sectional area and increasing both its longitudinal and transversal reinforcement. This technique can greatly increase the member’s flexural and shear capacity, as well as its ductility. Moreover, due to the increase in the dimensions and the addition of extra flexural reinforcement, the element’s bending stiffness also increases, a side-effect that might not be desirable in some cases. RC jackets of various types have been the topic of several experimental studies (e.g. [10], [11], [12], [13], [14], [15], [16]]) and have also have been widely used in practice in the recent past successfully.

Fig. 3

Fig. 3Recently, there is a tendency to replace the concrete in such jackets with high-performance materials, due to their higher durability and better mechanical properties. Within this field, a number of concrete alternatives have been proposed and are listed below.

High-performance, fiber-reinforced cementitious composite mortars (HPFRCC) may be used for the strengthening of the critical region of RC columns, even when they are corrosion-damaged. Such schemes can result in a significant reduction in shear and bending cracks, an overall enhancement of the force–displacement behavior, better energy dissipation and less stiffness degradation [17], [18]]. The use of self-compacting ultra-high-performance fiber-reinforced concrete (UHPFRC) in RC columns with insufficient lap slices, has also been found to eliminate bond failure and damage in the plastic hinge regions [19]. Other studies employed jackets made of ferro-cement [20], engineered cementitious composites (ECC) [21] and high-strength micro-concrete [22].

The seismic upgrading of RC members with RC or other high-performance cementitious mortar jacket has proved itself over the years both in the lab and in practice. The most important benefits and drawbacks of this family of strengthening techniques are summarized below:

+ Significant increase in strength and ductility.

+ Adaptable to any shape of section.

+ Makes use of materials that both engineers and workers are familiar with.

- Expensive, labor intensive and time-consuming method.

- Significant occupancy disruption.

- Loss in floor area due to the increase of the cross section sizes.

- Modification of the stiffness of the member.

- Use of large quantities of materials (i.e. concrete and steel) with high environmental burden (higher embodied CO2 emissions, more energy in manufacturing).

2.2. Steel jacketing

Instead of RC or other cementitious materials, structural steel can be used as external reinforcement to enhance the behavior of existing RC elements (Fig. 4). A combination of steel angles and plates can be used to form a cage around an RC element, thus increasing its flexural and shear strength, but also its ductility and stiffness [23], [24]]. Alternatively, tubed steel elements or sheets can be wrapped around elements to provide extra confinement to the inner concrete and that way increase its ductility and shear capacity [25], [26]]. In the latter case, the volume between the added steel and the existing concrete may be filled with grout.

Fig. 4

Fig. 4Recently, Fakharifar et al. [27] suggested a technique for the rapid repair of severely damaged circular RC columns using lightweight, prestressed steel jackets. This scheme consists of a thin steel sheet, wrapped around the RC element and restrained from buckling via the employment of several prestressed strands. The retrofitting process can be carried out by a group of two workers in less than 12 h and does not modify the initial column’s geometry. The method was able to restore the strength and ductility of the tested members to 115% and 140%, respectively; their stiffness though was not fully restored, approaching though 84% of the undamaged column’s stiffness.

More recently, Wang et al. [28] recommended an innovative approach for the seismic strengthening of rectangular RC columns, which support very high axial loads (normalized axial loads of ∼0.6). In this method, pre-cambered steel plates are applied on the opposite faces of the member and then post-compressed by tying them tightly together with anchor bolts. That way, through this pre-compression process, part of the axial load is transferred from the column to the new steel elements, relieving the former significantly. The experimental study showed that the strengthened columns can maintain their shear-carrying capacity under high axial loads and also exhibit significantly increased ductility, which can be fine-tuned by controlling the thickness and/or the initial pre-camber of the steel plates.

Upgrading RC elements with steel jacketing techniques is a less popular method in engineering practice, but it can still provide excellent solutions in specific cases. The most important strengths and weaknesses of steel jacketing related methods are summarized below:

+ Significant increase in strength and ductility.

+ Makes use of materials that both engineers and workers are familiar with.

- Relatively expensive, labor intensive and time-consuming method *.

- Occupancy disruption *.

- Need for corrosion protection.

- Modification of the stiffness of the member and addition of significant extra weight *.

(* These drawbacks are less significant in comparison to RC jacketing)

2.3. FRP jacketing

Probably the most popular technique for the seismic retrofitting of individual RC elements involves the use of fiber-reinforced polymers (FRP). When compared to traditional retrofitting methods, FRP are a very competitive alternative, as they offer ease and speed of installation, less labor work, minimum geometric changes, very high strength to weight ratio and minimum occupancy disruption (e.g. [29]). On the other side, they exhibit very poor behavior when exposed to high temperatures, in which case they need protection, and demand high quality work to be performed by experienced personnel. Yet, in the (not so common) case of open jackets (e.g. U-shaped jackets in T-beams), the effective utilization of the high strength of FRP may be low (e.g. in the order of 35%), due to the fact that debonding failures precede the material failures. The use of spike anchors increases the utilization of FRP tensile strength (see Section 2.3.2).

2.3.1. Fiber types

Fibers in FRP materials can be of various types. The most usual fiber type used in seismic retrofitting applications is carbon (CFRP), due to its high elastic modulus and excellent durability; however, it is the most expensive material as well. A lower cost choice is to use glass fibers (GFRP), however as glass has roughly 1/3 of carbon fibers’ elasticity modulus, larger material quantities need to be applied. Other fiber types that can be used (but are not common) are aramid, basalt, polyester, polyparaphenylene benzobisoxazole (PBO) and polyethylene terephthalate (PET). Lastly, it is also possible to form hybrid FRP by combining two or more materials together. Typical stress–strain curves for various types of fibers are given in Fig. 5.

Fig. 5

Fig. 52.3.2. Strengthening methods

2.3.2.1. General

FRP are normally used in the field of RC member strengthening as externally bonded reinforcement (EBR) and can be applied (typically) in two distinct ways. The first and most frequent is to use FRP in the form of fabrics (Fig. 6) and attach them to the concrete substrate using epoxy resins. This way, they can be used as shear reinforcement in beams and columns with insufficient stirrups in order to ensure a ductile flexural response. Moreover, when wrapped around columns they provide confinement to the inner concrete and that way significantly increase the section’s ductility. The application of fabrics is possible on simple cross section shapes (circular or rectangular with low aspect ratio) as well as on more complicated shapes (e.g. T, L, rectangular with high aspect ratio) through the use of anchors.

Fig. 6

Fig. 6Alternatively, and rather rarely in seismic retrofitting, FRPs can be used in the form of prefabricated laminates, strips or bars (Fig. 7) to act as external longitudinal or transverse reinforcement in existing elements and thus increase their flexural or shear capacity. Their application can be either external, on the faces of an RC member, or inside grooves, in which case we have the near surface mounted (NSM) method. It should be emphasized though, that when used as external flexural reinforcement, strengthened members do achieve higher flexural strengths, but lower deformation capacities as fibers fail (or debond) at significantly lower strains than reinforcing steel (e.g. see Fig. 5). Strengthening and seismic retrofitting solutions with FRP are summarized in Fig. 8.

Fig. 7

Fig. 7 Fig. 8

Fig. 82.3.2.2. Seismic retrofitting with FRP

When it comes to seismic retrofitting, FRP have been proved to be most effective when used in the form of sheets as shear reinforcement or as a means to provide extra confinement. A review on seismic retrofitting of RC with FRP is given in [29] and a more detailed treatment on the subject is presented in [30] and [8]. A few of the numerous other studies are summarized below.

Ma et al. [31] have observed that when shear-deficient RC columns are wrapped with CFRP, they exhibit stable flexural behavior, as is they can sustain numerous loading/unloading cycles with no or little strength loss. In their studies, the external reinforcement acted similarly to classical steel hoops, preventing shear-type failures and confining the inner concrete section, thus greatly increasing the section’s available ductility. In the studies of Sause et al. [32], Ghobarah and Galal [33] and Haroun and Elsanadedy [34], [35] it was also found that ductility was increased, column failure was delayed and that buckling of longitudinal bars could be avoided through the use of stiffer CFRP jackets. Comparable results were reported by Balsamo et al. [36] who employed a combination of CFRP sheets and laminates to seismically strengthen a full-scale RC frame.

Similar enhancement in seismic behavior has also been observed in RC members strengthened with GFRP jackets. Sheikh and Yau [37], Memon and Sheikh [38] and Youm et al. [39] have reported that GFRP wrapping improves the ductility, energy dissipation and capacity of RC columns, as well as the seismic performance of RC columns with insufficient lap slices.

Bousias et al. [40] studied the efficiency of CFRP versus GFRP jacketing on RC columns with or without corroded reinforcement. It was found that, for the same circumferential stiffness (FRP elasticity modulus times the jacket thickness), the effectiveness was the same. The same conclusion was also made by [41], regarding the stiffness being the decisive factor.

Concerning the cross-sectional geometry of the RC elements, Abdel-Mooty et al. [42], [43] found that confinement was most effective in circular sections, followed by square and then rectangular. This effectiveness was reduced in case the elements had already sustained some damage.

Harries et al. [44], Harajli and Dagher [45] and Harajli [46] examined the behavior of CFRP reinforced RC columns with lap slices. In their studies, they observed that the jackets improved significantly the bond strength of the spliced bars. This in turn resulted in higher capacity and ductility, but also lower pinching effect and bond deterioration.

In the studies by Ozcan et al. [47], [48] it was also observed that the rotation capacity and energy dissipation of CFRP retrofitted columns was increased. At the same time, the stiffness degradation was significantly reduced. Colomb et al. [49] studied the efficacy of continuous and discontinuous FRP wraps and concluded that the former are characterized by flexural failure while the latter exhibited a mixed flexure-shear behavior.

Pantelides at al. [50] showed that CFRP jacketing is an effective rehabilitation measure for improving the seismic performance of existing beam-column joints with inadequate seismic details in terms of increased joint shear strength and inelastic rotation capacity.

Prestressing has also been employed in combination with FRP jacketing, e.g. in the work by Zhou et al. [51], in order to overcome the stress hysteresis of FRP sheets relatively to the inner concrete. An overall improvement in terms of seismic performance was observed, as load capacity, ductility and energy dissipation increased.

Vrettos et al. [52] used carbon fiber spike-anchors as a means of anchoring longitudinally applied FRP fabrics in the form of externally applied flexural reinforcement for columns. The anchor efficacy was found to be almost linearly analogous to their weight; the higher the volume of fibers in each anchor, the higher the tensile strength it can carry. The tensile capacity of carbon fiber spike-anchors in connecting the column flexural (longitudinal) FRP reinforcement to the foundation block was also investigated by Bournas et al. [53]. It was confirmed that the carbon fiber spike-anchor is an effective anchorage system, which could be used in a range of strengthening applications including the seismic upgrading of RC columns. Pohoryles et al. [54] proposed the use of carbon fibre strands for the flexural strengthening of columns for eliminating single-storey mechanisms in RC frames.

Choi et al. [55] retrofitted RC columns with and without lap slices using tensioned GFRP winding wires. They observed that with this retrofitting method flexural capacity and drift at failure were increased, while at the same time, buckling of the longitudinal reinforcement, concrete spalling and splitting of the lap slices were prevented.

A comparative study was recently carried out by Yang and Wang [56] to assess the effectiveness of full CFRP versus strap CFRP wrapping as external reinforcement in shear-controlled RC columns. The retrofitted columns showed increased shear capacity and ductility, which dropped with higher axial loads. The authors concluded that, for the same volumetric ratio, CFRP straps were more efficient than full wrapping. Wang et al. [28] also examined the same problem for high-strength RC columns. Nonetheless, they observed that full wrapping of the elements would result in in better behavior.

Dai et al. [57] employed large fracture strain polyethylene terephthalate (PET) FRP and compared them to aramid FRP (AFRP). The tests they conducted on RC specimens showed that PET FRP increases the ductility significantly and does not rupture at the ultimate limit state, making itself an interesting alternative to conventional FRP. Liu and Li [58] recently compared the efficiency of conventional CFRP versus PET FRP on partially corroded columns. They reported that PET FRP exhibited similar performance with regard to the enhancement of their seismic behavior in terms of energy dissipation, damping ratio, hysteretic performance and stiffness degradation.

Chang et al. [13] used polyester FRP sheets for strengthening RC columns with insufficient reinforcement. In their study, retrofitted specimens showed ductile behavior, along with significantly increased energy dissipation.

Ouyang et al. [59] used basalt FRP (BFRP) and compared them to CFRP, applied on RC columns. Their results showed that BFRP retrofitted columns exhibited the same or even better performance than those retrofitted with CFRP. Taking also into account that BFRP sheets cost about one-fifth the price of CFRP sheets, the authors concluded that they are a competitive alternative.

2.4. TRM jacketing

Fiber Reinforced Polymers have been used widely over the last years as a means to achieve better seismic behavior in deficient RC elements, mainly columns. However, apart from their advantages related to their application in retrofitting schemes, FRP entail a number of problems, which are listed below [60]:

-

•

Resins behave poorly in high temperatures (above their glass transition temperature Tg), therefore the FRP reinforcement needs to be protected if it has to stay active during a fire.

-

•

Epoxy resins are expensive.

-

•

Application of resins has to be made on clean, dry surfaces, within regular temperatures and by experienced workers, as they are hazardous materials.

-

•

In case of wrapped elements, the final product is vapor impermeable, due to the zero porosity of the resins, something that may cause damage to the concrete below.

-

•

It is difficult to conduct a post-earthquake assessment of a strengthened element, as the FRP jacket will “hide” any damage suffered by the inner concrete.

A possible solution to address the above-mentioned issues is to use the same fibrous materials (carbon, glass, basalt etc.) in the form of textiles embedded in cementitious mortars, instead of fabrics impregnated in epoxy resins. These textiles are essentially fabric meshes made of long woven, knitted, or even unwoven fiber rovings in at least two (typically orthogonal) directions. The density (quantity and spacing) of rovings in each direction can be controlled independently, thus affecting the mechanical characteristics of the textile and the degree of penetration of the mortar matrix through the mesh.

The end material is called Textile Reinforced Mortar (TRM), but it can also be found in the literature by other names, such as Textile Reinforced Concrete (TRC) or Fiber Reinforced Cementitious Matrix (FRCM). TRM have demonstrated superior performance than FRP as strengthening materials at high temperatures (e.g. [61], [62], [63], [64]]), whereas the TRM mechanical behaviour has also been found satisfactory after exposure to fire [65], [66]]. Fig. 9 shows the application of TRM in RC columns and beams, respectively.

Fig. 9

Fig. 9As far as confinement is concerned, Triantafillou et al. [60] conducted a set of axial compression experiments using concrete cylinders and short rectangular columns, confined with TRM. They reported that TRM jackets can provide a substantial gain in the compressive strength as well as deformation capacity of concrete cylinders, with that gain being higher as the number of the confining layers increases. They also compared the efficiency of TRM jackets versus resin-impregnated (i.e. FRP) textile jackets and found that the former were only slightly inferior to the latter with respect to strength and ultimate deformation. Similar results were drawn from the tests on short rectangular columns, in which the performance of TRM was found to be very close to that of equivalent FRP jackets. Lastly, it was observed that the failure of TRM jackets was less abrupt than that of resin-impregnated textile jackets, a phenomenon that was attributed to the slowly progressing fracture of individual fiber bundles.

Bournas et al. [67] studied the effectiveness of TRM jackets as a means of confining RC columns with limited capacity and compared them to FRP jackets. A significant increase was again observed in terms of both strength and ultimate deformation. Moreover, when compared to FRP jackets of equal stiffness, TRM jackets were found to be slightly less effective (by about 10%) in terms of increasing strength and deformation capacity. Cyclic uniaxial flexure tests on large-scale RC columns showed that TRM jackets are very effective as a means of increasing the cyclic deformation capacity and the energy dissipation of old-type RC columns with poor detailing, by delaying bar buckling. Therefore, they concluded that TRM jacketing has practically the same effectiveness as FRP jackets of the same stiffness and strength.

In a subsequent study, Bournas et al. [68] investigated the effectiveness of TRM jackets in confining RC columns with limited capacity due to bar buckling or bond failure at lap splice regions. Experimental results indicated that TRM jacketing was quite effective as a means of increasing the cyclic deformation capacity of old-type RC columns with poor detailing, by delaying bar buckling and by preventing splitting bond failures in columns with lap-spliced bars. Compared with their FRP counterparts, the TRM jackets were found to be equally effective in terms of increasing both the strength and deformation capacity of the retrofitted columns. An in-depth experimental investigation as well as an analytical model for columns with lap-splices is given in Bournas and Triantafillou [69], whereas an in-depth analytical investigation of the problem of bar buckling is presented in Bournas and Triantafillou [70].

As far as shear strengthening is concerned, Triantafillou and Papanicolaou [71] tested shear-dominated RC members, strengthened with closed TRM jackets. The jackets were effective in transforming the failure mechanism from shear to flexural and that way prevent a brittle response. Compared to FRP jackets, the authors stated that the TRM strengthening system was about 55% as effective.

Tetta et al. [72], [73], [74] explored systematically the shear strengthening of RC beams with TRM jackets, investigating the TRM vs FRP jacketing in side-bonding, U-wrapping and full-wrapping, different number of the strengthening layers and the effect of the shear span-to-depth ratio in beams strengthened in shear with U-shaped TRM jackets. They concluded that the TRM is generally less effective than FRP in increasing the shear capacity of concrete; however the effectiveness depends on both the strengthening configuration and the number of layers. U-wrapping strengthening configuration is much more effective than side-bonding in case of TRM jackets and the effectiveness of TRM jackets increases considerably with increasing the number of layers. It was also concluded that the shear span-to-depth ratio has no effect on neither the failure mode nor the contribution of the TRM jacket to the total shear resistance of the beams.

Tzoura and Triantafillou [75] did a large set of cyclic loading tests experiments on RC T-beams strengthened in shear using U-shaped TRM jackets. Mechanical anchors through the RC slab were also used to provide end anchorage to the jacket. In this study, it was concluded that the jacket effectiveness increases substantially when steel anchors are employed and that high strains can be achieved in the TRM. Moreover, it was stated that TRM U-jackets are nearly as effective as FRP U-jackets in increasing the shear capacity of RC T-beams.

Tetta et al. [76] tested 10 full-scale RC T-beams strengthened in shear with TRM jackets and textile-based anchors. Their study concluded that: (1) the use of textile-based anchors increases dramatically the effectiveness of TRM U-jackets; (2) increasing the number of layers in non-anchored jackets results in an almost proportional increase of the shear capacity; and (c) TRM jackets can be as effective as FRP jackets in increasing the shear capacity of full-scale RC T-beams.

A simple design method for the calculation of the contribution of TRM jacketing to the total shear resistance of RC beams is presented by Tetta et al. [73], [74]. The method predicts reliably the expected failure mode in a TRM system based on the characteristics of its textile reinforcement and the mortar properties.

A detailed treatment of TRM and their use in seismic retrofitting can be found in Koutas et al. [77].

2.5. Hybrid jacketing systems

Via the concurrent employment of different strengthening techniques, a more efficient retrofitting scheme can be designed and achieved. The next sections present the main developments on this subject during the last years.

2.5.1. FRP/TRM jackets with NSM reinforcement

The most common hybrid method found in the literature is the combination of FRP/TRM jackets with NSM strips. These systems result in flexural and shear strengthening, as well as in confinement, without affecting the member’s dimensions.

Wu et al. [78] embedded GFRP bars into the plastic hinge zone of RC columns combined with normal CFRP jackets. The bars were perpendicular to the member axis with the purpose of expanding the effectively confined zone. They observed that concrete failure was suppressed and rebar buckling was prevented, thus increasing the members’ ductility and energy dissipation by a factor of three.

Bournas and Triantafillou [79] strengthened RC columns using different types of NSM materials (FRP and stainless steel) combined with TRM jackets (Fig. 10). They reported that NSM FRP or steel are effective in increasing a member’s flexural strength, by a factor of up to two, without diversely affecting its deformation capacity. Moreover, it was observed that the TRM jacket was very effective in controlling the buckling of the NSM bars, thus allowing them to reach high strains until failure. Subsequently, Bournas and Triantafillou [80] presented an analytical model for the analysis of RC columns strengthened in flexure with NSM reinforcement and confined with TRM jackets for cross-sections subjected to biaxial bending combined with axial loading.

Fig. 10. (a) NSM strips combined with (b) TRM jacketing.

Source: [79]Sarafraz and Danesh [81] also used NSM FRP in combination with CFRP jackets and reported a significant increase of up to 86% in the flexural capacity of RC columns, as well as an overall improvement in the members’ seismic performance. Li et al. [82] applied the same technique (NSM GFRP with CFRP jackets) and added CFRP anchors in the plastic hinge region of RC columns with cross section dimensions of high aspect ratio. They reported that NSM GFRP rebars increase the flexural strength by up to 51%, while CFRP jackets with CFRP anchors increase both the strength and ductility of columns by 27% and 72% respectively.

Napoli and Realfonzo [83] combined NSM longitudinal rebars into grooves cut into RC columns with steel angles; then they wrapped the whole system with CFRP jackets. The authors observed a significant increase in the members’ flexural strength and deformation capacity by up to 60% and 30% respectively.

FRP jackets have also been combined with NSM FRP other than glass or carbon. Seyhan et al. [84] used aramid FRP and were able to achieve up to 90% higher flexural strength, as well as satisfactory drifts of 3%. Similarly, Fahmy and Wu [85] as well as Jiang et al. [86] used basalt FRP and obtained very good results in terms of both flexural capacity and ductility.

Seifi et al. [87] used NSM steel rebars and GFRP in combination with CFRP jackets, to strengthen deficient RC columns, which were under-reinforced with plain bars and had insufficient lap slices. Significant improvements were reported for the flexural strength (two times higher), energy dissipation (more than three times higher) and hysteretic damping (two times higher). The use of steel rebars over GFRP as NSM reinforcement led to approximately 10% higher lateral strengths and 16% higher drifts.

Recently, Shin et al. [88] studied experimentally the seismic behavior of non-ductile building frames retrofitted with the NSM-FRP hybrid system. The full-scale dynamic testing was performed on the retrofitted test frame to realistically measure dynamic responses and quantify the retrofit effects. The hybrid retrofit system reduced the peak inter-story drift of the first-story columns by about 25% and their hinge rotation by approximately 76%. Additionally, the retrofit system uniformly distributed the damage or drift over the entire structure.

2.5.2. FRP and steel jacketing

The combination of CFRP jackets with steel elements was first examined by Realfonzo and Napoli [89], who used steel angles together with FRP wraps to strengthen RC columns. It was concluded that a great improvement in the flexural response can be achieved (up to two times higher), provided that the steel angles are anchored in the foundation of the RC elements. Li et al. [90] combined CFRP and steel jackets in order to enhance the seismic behavior of corrosion-damaged RC columns. They reported that the combined use of CFRP and steel was more effective in improving the strength and ductility of a member, than the use of only one material. Furthermore, according to their work, the higher the degree of corrosion or the axial load, the more noticeable the strengthening effect; an up to 50% strength increase and four times higher deformation capacity were achieved.

ElSouri and Harajli [91] studied the seismic performance of RC columns with lap slices, strengthened with steel ties as well as FRP jackets externally. They reported that retrofitted elements withstood up to 60% higher lateral loads and drifts, dissipated more energy and experienced less damage.

Chou et al. [92] strengthened RC columns using a corrugated steel tube wrapped with GFRP sheets, in order to create a ribbed surface between the concrete substrate and the FRP jacket. They reported that, by adding extra GFRP sheets, the failure mode changed from shear to flexural; also this system increased significantly the drift capacity by almost six times, as well as the energy dissipation.

In order to retrofit corrosion-damaged RC bridge columns, Afshin et al. [93] suggested a composite steel (inside) – CFRP (outside) jacket. They reported an improvement in the energy dissipation and the strength degradation characteristics of the response, but they did not observe any significant improvement in the ductility.

2.5.3. Steel/FRP and high-performance materials

Repair/strengthening and/or seismic retrofitting of damaged RC elements has been achieved by combining composites with high-performance cementitious mortars. Ma and Li [94] repaired damaged RC columns using fast curing early-strength cement mortar along with basalt FRP and reported a significant improvement in both energy dissipation (by around 50%) and ductility (by two times). The flexural strength of moderately damaged elements was fully restored; when the damage was more severe though, a full capacity restoration could not be achieved.

Xue et al. [95] combined high-performance fiber-reinforced (steel or polymer fibers) concrete (HPFRC) with steel rebars to repair severely damaged RC bridge columns. This technique was not only able to fully restore the member’s strength, stiffness and ductility, but also increased its energy dissipation by around 30%; HPFRC with steel fibers was more efficient with respect to that matter.

Cho et al. [96] used high-performance fiber-reinforced cementitious composite (HPFRCC) sprayed mortar together with steel bars in order to enhance the seismic behavior of under-reinforced RC columns, typical of old constructions. They performed cyclic lateral loading tests, which showed that the retrofitting technique was effective in increasing the columns’ lateral strength by 20% and achieving a many times higher deformation capacity, by altering the failure mode from shear to flexure. Cracking was also reduced, and higher energy dissipation was observed.

Recently, Rajput et al. [97] repaired corrosion-damaged RC columns with HPFRC in combination with GFRP jackets. They reported that the performance of the retrofitted columns was adequate in terms of restoring the member’s load capacity, but it could not satisfy the ductility demands, posed by modern regulations.

3. Global measures

When a drastic increase in the lateral load capacity or the stiffness of a structure is needed, it is very likely that local retrofitting measures alone either would not suffice or would demand such extended interventions that the final retrofitting scheme would become uneconomical. In such cases, global measures are employed, aiming at either increasing the structure’s lateral strength and stiffness or decreasing the seismic demand. The former is usually achieved by adding new structural elements to the existing building, thus increasing significantly its lateral stiffness and resistance. The alternative of decreasing the earthquake-induced forces to a given structure in the first place, is normally achieved through the employment of base isolation systems or energy dissipating devices (dampers). The following sections provide a state-of-the-art description of such retrofitting schemes, which are applicable to RC buildings.

3.1. Capacity increase

3.1.1. Addition of bracing systems

An effective way to increase a building’s stiffness and strength characteristics is by adding a bracing system within selected frames. The new elements can be tailored to take up the lateral loads almost entirely, but since they have to work in conjunction with the existing frame members, great care must be paid to their connections to the frame elements as well as to the increased axial loads, which will be induced to the columns. Furthermore, as the retrofitting works are normally done on the outside frames of the structure, the loss in living space area and the occupancy disruption are minimal. A number of different bracing types exist and can be employed to RC structures. The most usual is that of concentric bracing (Fig. 11a), in which the horizontal seismic forces are resisted by axially loaded members. Alternatively, eccentric braces (Fig. 11b) resist the horizontal forces by a combination of axially loaded members and shear links, which are used as energy dissipating mechanisms.

Fig. 11

Fig. 11To address the problem of buckling, which is inherent in braces, buckling-restrained braces have been developed and constitute another viable option. Last, but not least, post-tensioned rods or prestressed cables is a relatively new retrofitting scheme which can also be employed to solve buckling-related problems.

3.1.1.1. Concentric braces

Concentric braces are the most widely used type of braces for retrofitting RC frames. The high axial forces (tensile and compressive) developed in the added members resist lateral loads through their projections to the horizontal direction. Appropriate types of concentric braces that can be used for retrofitting RC buildings are diagonal bracings, X-bracings and Λ- or V-bracings. K-braces on the other side should not be used because they introduce high shear forces to the columns they converge to [98].

Experimental and analytical investigations have shown that concentric braces can significantly increase the strength and stiffness of under-designed RC frames [99], [100], [101]]. Moreover, the fact that they can be attached on the external faces of a building’s frames in a short period of time, makes them a very appealing retrofitting option both in terms of aesthetics but also in cases which occupancy disruption should be kept to a minimum. On the downside, concentric braces do not seem to improve the ductility of the retrofitted structure, since their mode of failure is buckling of the compressed members.

3.1.1.2. Eccentric braces

To avoid buckling of the compressed diagonal element and increase the ductility of the braces, one option is to connect them eccentrically to the surrounding frame. This is achieved using Λ-shaped braces, which are not connected directly the frame’s beam, but through a shear link (e.g. Fig. 10b); a short element which is tailored to develop plastic deformations before any buckling occurs. Since all the damage is concentrated in this, small element, its replacement can easily be carried out in cases it has been deformed excessively.

Experimental investigations have shown that this retrofitting method can result in a considerable increase of the building’s capacity (e.g. [102]). The increase in the stiffness is also important but less than in the case of concentric braces [103]. At the same time it improves its ductility and provides an effective means for energy dissipation [104], [105], [106]].

3.1.1.3. Buckling-restrained braces

Eccentric braces, when designed correctly, do not exhibit buckling failure types. However, they do that in the expense of the frame’s lateral stiffness, which in some cases might be necessary. A possible solution to that is to use concentric buckling-restrained braces (BRBs). BRBs consist of a steel core element, which is encased into a steel tube, filled with an unbonded material. That way, only the core element is stressed, while the outer tube provides out-of-plane stability, thus eliminating the possibility of buckling during the compression of the element.

Various research programs on BRB have been performed and shown that this retrofitting technique can effectively increase a frame’s strength, stiffness and ductility at the same time. Large axial strains can be achieved without buckling occurring prematurely [107] and high ductility gains are possible as well [108]. To fully avoid buckling failure, Wada and Nakashima [109] suggested that the Euler buckling load must be 50% higher than the yield load of the element. The feasibility and effectiveness of using BRBs as a means of upgrading existing RC structures was also shown in a series of numerical studies (e.g. [110], [111]]).

3.1.1.4. Post-tensioned cables

The last option to avoid the buckling failure types, which are common to concentric braces, is by using post-tensioned cables instead of a traditional bracing system [7]. These cables are made of strands which are placed inside steel or PVC ducts with adequate protection against corrosion and can easily be applied on building facades and extend over more than one storey. If not prestressed at all, such cables exhibit elastic buckling upon the slightest compressive load and remain inactive (and undamaged) until the load reverses and tension is induced to them. If they are prestressed though, they are also active when “compressed” and thus able to contribute to the lateral resistance of the structure. At the same time though, the higher the amount of prestress, the lower the margin until tensile yielding occurs, leading to larger accumulation of inelastic strains and loss of prestress.

Prestressing forces of 20% to 75% of the cable yield force have been reported [112], [113], [114]]. It is important to note that in case of high initial prestress, the prestressing forces exhibit significant time-dependent losses (mainly due to cable relaxation) and therefore the cables must be re-tensioned periodically. Last, but not least, since pretensioning induces axial compression in the RC columns, it might be necessary to strengthen them using some jacketing technique (see section 2). That way, the adverse effect of high axial load on their ductility can be mitigated.

3.1.1.5. Steel plate shear walls

The use of metal Steel Plate Shear Walls (SPSWs) (or shear panels) for the seismic retrofitting of existing RC structures was examined by Formisano et al. [115]. Slender steel panels were inserted in both frames of the ground floor of an existing building, which was tested on site. The panels were bolted on steel elements, which were then connected firmly to the beam and foundation of the RC frame, thus providing the composite action. An impressive, ten-fold increase of the lateral strength was observed, with the respective stiffness being double that of the initial structure.

Since SPSWs can achieve a significant strength increase, it might also be necessary to strengthen the boundary RC members in order to withstand the higher stresses transferred to them. To avoid such costly interventions, Formisano et al. [116] proposed the use of perforated SPSWs to fine-tune the amount of the extra strength added through the system. Numerical simulations showed that drilling percentages of 40% and 60% of the plate area could provide significant cost savings of 16% and 27%, without excessively compromising the strength and stiffness of the retrofitted structure.

3.1.1.6. Steel exoskeletons

A recently proposed retrofitting scheme for RC frames involves the application of diagonal grids (“diagrids”) from the outside of existing RC buildings, in the form of a 3D lattice structure, called exoskeleton (Fig. 12). Diagrid diagonal members are designed to intersect at floors, where they are connected to steel horizontal ring beams, which have the double function to stabilize the diagrid exoskeleton and to collect and transfer the seismic forces from the building floor diaphragms to the diagrid and to a new foundation system. Diagrid exoskeletons may be combined with thermal insulation, to offer integrated solutions for combined seismic and energy retrofitting (e.g. [117], [118]]).