Robotics uses model predictive control (MPC) methods frequently because they ensure viability and enable the computation of revised trajectories while the robot is in motion. Nonlinear MPC-based trajectory tracking with or without obstacle avoidance has been widely discussed priory, but there is no discussion has been made on fuel minimization. This work develops a model to obtain the optimal trajectory to move a manipulator between two locations with the lowest amount of fuel rate through a data-driven nonlinear MPC approach with an extended Kalman filter. The study showcases both first-principles and neural network approaches for modeling the robot's dynamics, highlighting the trade-offs between accuracy and computational cost. This model guides the robot to follow the best possible path in closed-loop design. We assume that there are four physical thrusts of a range of 0–1 in the robot to achieve the same manage freedom. The key performance metrics were 8.39 units for planned fuel consumption, 11.99 units for closed-loop, and 16.867 units for the neural network architecture. The simulation result of the closed-loop performance reached the chosen place with a 12% more fuel expense compared to the scheduled optimal route. Therefore, for future MPC implementation, this work explores the neural state space network as an alternative potential to the first-principles models.

The mobility plan of collaborative robots must be adjusted to a dynamic environment and a variety of work limitations. At the moment, they detect collisions and stop or delay their motion plan to avoid harming people or objects (Krämer et al., 2020). Since continuum robots' mathematical models are intricate and current modeling techniques are inaccurate, controlling them precisely is a particularly difficult challenge. Therefore, even the most sophisticated control algorithms have performed poorly, especially in terms of trajectory tracking precision (Amouri et al., 2022). A nonlinear affine system with limitations on acceleration and velocity makes up the mobile robot kinematic model. As a result of the physical restriction, the standard control methods could be unable to resolve the tracking issue (Hu et al., 2019). In comparison to conventional designs with rigid torsos, other multi-degree-of-freedom robots, such as those with flexible spines based on tensegrity structures, may offer advantages. However, because of their high-dimensional nonlinear dynamics and actuator restrictions, these robots can be challenging to operate (Sabelhaus et al., 2021).

Robotics uses model predictive control (MPC) methods frequently because they ensure viability and enable the computation of revised trajectories while the robot is in motion. To get good performance, they typically need heuristic references for the tracking terms and careful tuning of the cost function's parameters. For instance, the algorithm's performance may suffer when a legged robot must respond to environmental disturbances (such as recovering after a push) or track a specific target using statically unstable gaits (Bratta et al., 2023).

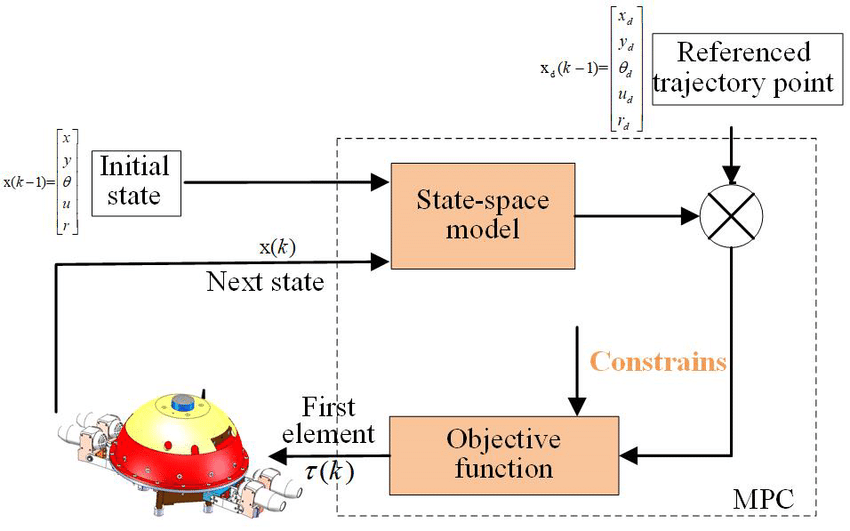

MPC is essential for creating the most suitable decisions in various applications, including independent tracking and trajectory following. For energy-efficient commands, MPC presents substantial fuel cost reductions in structural processes (Jain et al., 2020). MPC is a feedback control method that computes potential process outputs using a model. One important use of the MPC is that it makes predictions about future trajectories depending on the control actions the plant decides to take. The system then determines the best course of action to bring the anticipated trajectory as close as feasible to the intended trajectory.

Larger systems would also require tweaking too many controller gains, making their design much more difficult. The MPC has the advantage of being a multivariable controller that simultaneously regulates the outputs and takes into consideration all of the interactions between the variables in the system. The ability to manage restrictions that are necessary because breaking them can have unfavorable effects is another virtue of MPC. The preview functionality of MPC, which is comparable to feedforward control, is another feature. To enhance the performance of the controller, MPC may readily include future reference data in the control problem. Since the 1980s, model predictive controllers have been employed in the process sector. Microprocessor use has expanded to numerous fields as a result of their increased computational capacity. MPC offers all of these advantages, but it should be noted that it needs a strong, quick processor with a lot of memory. And the reason is that each time step in MPC involves solving an online optimization problem (Ruiz-Moreno et al., 2022).

Nonlinear MPC (NMPC) is an efficient method to overcome optimal trajectory challenges since it handles the nonlinear optimization problems of a constrained open-loop plant with given current states (Narasingam et al., 2023; Bemporad, 2023; Han et al., 2021; Zhang et al., 2017). A nonlinear dynamic model is now available, allowing MPC to make decisions with greater precision.