Introduction

Most chemical engineers do not learn about economics in their curricula. What is taught as ‘process economics’ focuses on estimating the cost of products and processes and on calculating metrics related to profitability such as net present value (NPV) and return on investment (ROI). This is closer to cost accounting than to economics. Economics is defined in the Merriam-Webster dictionary as ‘a social science concerned chiefly with description and analysis of the production, distribution, and consumption of goods and services.’ The connection of engineering with economics is apparent from this definition since production and distribution of goods and services often involve engineering activities. Consumption depends on the behavior of markets and human preferences, and plays a critical role in the economic feasibility and sustainability of engineering activities. Economic policies are a common mechanism to influence human behavior, which in turn affect consumption and production of engineering products.

Despite this close connection between economics and engineering, most existing engineering methods do not account for this interaction. That is, most engineering decisions ignore the effects of markets and human behavior. Consider the following examples:

-

•

Effect of a carbon tax. Consider the effect of an economic policy such as a carbon tax on CO2 emissions. Most process systems engineering approaches account for this tax by calculating the additional expense due to the tax by multiplying the quantity of CO2 emitted and the tax rate. This additional expense reduces the profit, which may change the optimal design. However, in practice, this is not how the effect of the carbon tax will be felt on the process. The tax will affect all activities throughout the economy: it may change the price of raw materials, utilities, capital, and the products and byproducts from the system being designed. The extent of this effect will depend not only on the CO2 emissions from the process, but also on how the process interacts directly and indirectly with the broader market and human preferences reflected by the relation between prices and consumption.

-

•

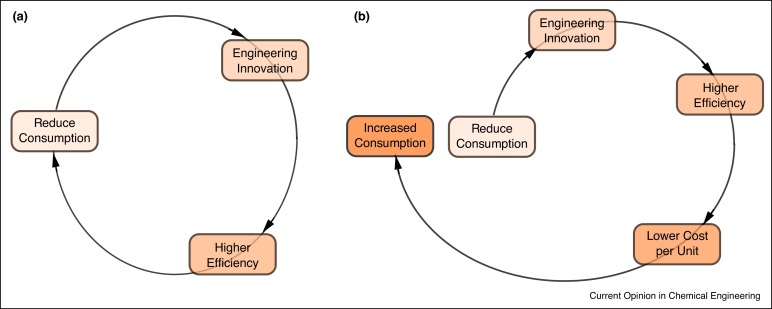

Effect of increasing efficiency. Consider a more efficient technology such as an LED light bulb that consumes 9 W instead of the 60 W consumed by an incandescent bulb to provide the same luminosity. It is common for engineers to assume that by adopting an LED bulb, society will reduce its electricity consumption by 85%, and as more bulbs are produced, this saving will increase in proportion to the number of bulbs. The mental model that most engineers have about the benefits of greater efficiency is shown in Figure 1a. As shown, the goal of greater efficiency motivates innovation, which results in the development of more efficient technologies and saving of energy. Engineers assume that these benefits of technology translate proportionately to societal benefits. However, reality is often different. In practice, as depicted in Figure 1b, a more efficient technology is usually less expensive per unit of service provided. For example, even though a single LED bulb costs more than an incandescent bulb, its cost per lumen of light is less [1]. Basic economics tells us that if the price of a good decreases, its consumption is likely to increase. Therefore, a more efficient technology can encourage consumption, resulting in greater use of resources in society, with the net result being an increase in overall consumption that may partially or completely nullify the benefits of increasing efficiency. This ‘rebound effect’ was first suggested by English economist Stanley Jevons who observed that improving efficiency of coal combustion encouraged the consumption of coal [2]. It is also called the Khazoom–Brookes paradox [3,4], and has been empirically observed for a large number of products such as light bulbs, appliances, chemicals, electronics, etc. [1,5•,6].

Figure 1. (a) What most engineers assume about the effect of engineering innovation versus (b) the actual effect of such innovation due to the economic rebound.

Figure 1. (a) What most engineers assume about the effect of engineering innovation versus (b) the actual effect of such innovation due to the economic rebound.

Ignoring such connections between the economy and engineering systems means that many designs and decisions are likely to be suboptimal and may even cause unintended harm to society and the environment. To reduce the chance of such harm, methods such as life cycle assessment, carbon footprint analysis, and many others have been developed and adopted to guide engineering decisions toward environmental sustainability [7]. These methods consider a large system boundary to reduce the chance of shifting the environmental burden along the life cycle, but the resulting metrics are usually normalized per unit of a product or activity, making them intensive in nature. Approaches such as eco-efficiency [8] that have been popular in industry also rely on such metrics, examples being energy and water use per unit produced or per monetary value of product. Intensive metrics can be misleading since their value can decrease to show improvement, while the absolute value without normalization can worsen. Environmental impact depends on the absolute value, which is an extensive variable and is without normalization. Thus, popular approaches for sustainable engineering often ignore the role of markets and human behavior.

In this article, we provide an overview of some of the approaches that are being developed to account for the interaction between economics and engineering. Most of these approaches are related to methods for assessing sustainability such as life cycle assessment. This is followed by a short discussion of approaches that can be used for process and product design.

Sustainability assessment

Attributional

Conventional life cycle assessment (LCA) and process engineering approaches based on it are ‘attributional’ in nature. Here, the analysis and design are done with intensive objectives such as cost or environmental impact per unit of product. These approaches ignore the interaction of economics and engineering and assume the full adoption of an available alternative in the market. Also, these approaches fail to consider the economic and societal consequences of technologies such as decreased price and increased consumption. Accordingly, attributional approaches rely on the model that is depicted in Figure 1a. Some of the important factors missed out by attributional LCA include the following:

-

•

Constraints of resource availability that prevent the complete substitution of a conventional technology with a new technology.

-

•

Constraints on the use of the new technology due to lack of the needed supporting consumption framework. For example, electric car use is still constrained by the fact that a charging network for such cars is not widely prevalent as compared to gasoline stations.

-

•

Constraints of physical production, energy and mass balances that limit the production of a certain material while selectively increasing or decreasing production of byproducts. For example, significant decrease in demand of gasoline will reduce functioning of refineries such that production of other valuable petrochemicals like jet fuel and kerosene may also decrease.

-

•

Constraints due to consumer behavior such as on the assumption of complete adoption of a new technology without accounting for changes in factors such as prices, income, budget, and the overall economy.

Short-term and selected marginal changes

This approach considers immediate consequences of marginal changes due to introduction of a new technology or product [11, 12, 13], and is referred to as conventional consequential LCA. By using market information and asking pertinent questions to experienced agents, this approach expands the system under study to include those processes that are likely to be affected and are in close competition with the studied process or product. It also requires data from product manufacturers to identify physical, technological and economic constraints. However, it does not capture broad and long-term consequences across multiple economy sectors. This approach is analogous to the approach used in conventional LCA for allocation by displacement and system expansion.

For the biofuel application mentioned in the previous subsection, this approach would consider marginal changes in flows that are affected by using biofuel instead of gasoline. The availability of agricultural land area for corn would be utilized as a constraint in the consequential LCA study that limits the supply of corn. Co-products from the biofuel production can replace other products that are available in the market [11]. These selected marginal changes are identified in the approach. Land use changes can also be identified through this method and environmental impacts from such changes can be included in the analysis. Marginal changes in consumption of conventional fossil fuels that would be replaced by biofuels will also be considered.

Short-term and economy-wide changes

Here we consider the short-term effects of introducing a new product or technology into the marketplace by using economy-wide input–output (IO) models. Use of environmentally extended IO models helps quantify environmental flows [14]. Societal impacts such as effects on jobs and wages, and economic effects such as on the gross domestic product may also be quantified. This model can be extremely comprehensive and cover a large number of economic sectors across many regions of the world. The model can also consider the simultaneous use of competing technologies by including economy-wide resource constraints such as maximum available capital budget, land area, and water supply in each region [15,16]. Therefore, the approach can model the effect of emerging technologies and its consequences in the market. However, it does not consider the effect of new technologies on prices or consumption, and therefore only provides a short-term snapshot of the economy by capturing the period after the new technologies are available but before changes in prices and demand kick in. IO models can also consider the short-term effects of economic policies such as taxes [17].

The biofuel example can now be modeled by accounting for region-specific market constraints such as the availability of economy-wide capital and land. Also, the model can consider food production that competes with biofuel production [18]. The consequence of biofuel technology across economic sectors and geographical regions can also be investigated.

Long-term effects with price elasticities

The effect of changes in consumption and prices is captured by general equilibrium models. A computable general equilibrium (CGE) model describes all the microeconomic activities in an economy, such as price elasticities of supply and demand, market clearing constraints, production and consumption functions, maximization of profits of different agents in the model, such as government, investment agents, producers, household and foreign markets. CGE models can determine consequences of policies and other decisions through the determination of marginal technologies, capture price effects, import–export decisions, tax policy effects, labor and capital constraints, along with non-marginal consequences such as the rebound effect [19]. The introduction of new technologies or products is modeled as an exogenous shock to the CGE model and over time, after a perturbation, markets reach a new equilibrium based on changes in the demand, supply and prices. Partial equilibrium models also capture such behavior but for a narrower category of economic flows [20]. Boumann et al. [21] initially explored the use of partial equilibrium (PE) and computable general equilibrium (CGE) models to perform consequential LCA.

These models are more widely accepted among economists, but they are more difficult to find or formulate than models used in other methods described in this section. Equilibrium models also represent all flows in monetary units, which may pose challenges in integrating them with engineering models, which usually use physical units. The challenges with using CGE models come from the fact that these are highly aggregated, with a small number of economic sectors modeling the entire economy. Thus, studying a particular product or technology becomes very difficult. Along with that, the assumptions on which CGE models are built, such as markets always reaching equilibrium and consumers being rational and maximizing their utility, increases uncertainty in the model results [22, 23, 24]. PE models on the other hand, represent a few chosen sectors of the economy and they maximize net social payoff. The prices of the specific goods considered are obtained independently from prices and quantities in other markets [25]. Consequential LCA with these models has been applied and explored in several studies [26, 27, 28, 29, 30, 31, 32]. Igos et al. [33] created a multiscale framework combining PE and CGE models to study energy policy scenarios.

Price changes in conventional fuels, agricultural products, etc. due to the introduction of biofuels can be estimated by consequential LCA with CGE models [34]. The rebound effect due to those price changes can be estimated as well. These models also provide an appropriate mechanism to estimate the effect of economic policies such as a carbon tax on the wider economy. The direct effect of a tax can be quantified on sectors such as fossil fuel burning power plants, and their effect on prices of products that rely on the generated electricity can be quantified, along with the change in consumption of products due to price changes.

Sustainable design

Some efforts in process and product design have included the role of the micro or macro economy. For example, frameworks for product design consider consumer behavior by including micro-economic aspects [35,36•]. The role of the macroeconomy in process design has also received some attention [34,37••]. Recent efforts toward sustainable process design have resulted in the process-to-planet (P2P) multiscale framework [38] to integrate models and data from engineering, life cycle assessment, and economics. By capturing the economy with input-output models, this framework has been applied to various examples [39], but this work is analogous to attributional methods described in Section ‘Attributional’, and is limited by its inability to consider price and demand elasticities. Recent work is expanding this framework to include consequential aspects by tighter integration with more advanced economic models. This includes using the rectangular choice of technology model [15,16,18] to extend methods described in Section ‘Short-term and economy-wide changes’ to account for market effects and constraints in process design [40••]. Some shortcomings of IO models may be overcome by including price elasticity information within an iterative framework [17]. Replacement of the IO model in the P2P framework with general and partial equilibrium models allows the incorporation of micro-economic and macro-economic effects, price and elasticity information into process and supply chain design [37••,41••]. The resulting framework is depicted in Figure 2.

Figure 2. Integration of models and data from engineering, life cycle assessment and economics for consequential sustainable design by the P2P framework.

Figure 2. Integration of models and data from engineering, life cycle assessment and economics for consequential sustainable design by the P2P framework.Conclusions

Despite the strong interaction of engineering decisions with markets and human behavior, few methods take this connection into account. It is widely believed that technological advances toward greater efficiency are needed for reducing environmental impact. However, many studies show that a higher efficiency often results in an increase in environmental impact because of the interaction between engineering and economics. This paper provides a brief overview of approaches that are being developed to address such shifting of environmental impact across disciplinary boundaries. Efforts toward consequential life cycle assessment are resulting in tighter integration with economic models. Similar efforts toward sustainable process design can benefit from multiscale frameworks such as P2P. In addition, appropriate policies are also essential for addressing rebound [42], and need to be integrated in the framework of sustainable engineering. Such methods are needed to satisfy one of the six requirements for claiming sustainability and for an engineering that makes positive contributions to sustainable development [43].