Introduction

Currently, in the United States, the most common biobased feedstocks to produce biofuels are corns and soybeans for ethanol and biodiesel production, respectively. In 2018, 38% of the total harvested corn in the nation was used for ethanol production [1] and 32% of soybean was used for biodiesel production [2]. Of the 16 billion gallons of ethanol produced, more than 94% were from corn starch [3], while of the 2 billion gallons of biodiesel produced, 57% were from soybean oil [4]. The supply and demand of these feedstocks for fuel production could impact their cost and availability as foodstocks. Many studies have exposed the disadvantages of using foodstocks as raw materials for chemical production [5]. Some countries are using forest lands to cultivate oil crops for fuel production [6,7], worsening the loss of natural carbon sinks in forests and wet pit. These practices defeat the purpose of producing biofuels to reduce or reverse the impacts of greenhouse gas emissions to climate change. Life cycle analyses (LCA) have demonstrated that corn ethanol production actually increases CO2 emissions when the system analysis includes fertilizer (generated from natural gas) inputs to achieve specific corn yields per acre [8,9]. Competition for food resources (e.g. land and agricultural products) to produce fuels and chemicals could adversely impact food security, cause price hikes, and raise ethical and technical issues about the benefits of the bioeconomy.

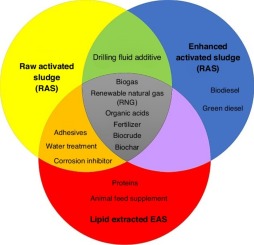

Integration of waste activated sludge (WAS), a mixed microbial consortium and by-product of wastewater treatment, and cellulosic biomass grown on idle lands or for the specific purpose of energy production (energy crops) could be an effective resource recovery and biorefinery model to produce biofuels and numerous specialty chemicals [10,11]. The benefits of using microorganisms, specially from waste sources, are often overlooked. Microbes are composed of numerous compounds, such as proteins, carbohydrates, lipids, extracellular polymeric substances (EPS), and glycolipids. Furthermore, microbes can be grown to produce compounds for specific applications and use the remaining parts of the cell, after extraction or excretion of the main compound of interest, to produce an array of useful compounds with applications in several industrial sectors. Lipids can be used to produce biofuels and lubricants, proteins can be the main raw material for the synthesis of adhesives, and EPS has been evaluated as a potential corrosion inhibitor. These are just a few examples of the variety of products and applications that could be generated from microbial components illustrated in Figure 1. Numerous investigations have been conducted on the production of renewable bioproducts and energy using microorganisms [10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20,21•,22,23,24••,25, 26, 27, 28, 29, 30,31•,32•,33,34,35•,36,37•,38, 39, 40]. As mentioned above, WAS is a common byproduct of wastewater treatment plants (WWTP). It is mostly considered a waste, even though at some facilities, WAS is digested anaerobically to recover biogas for power [41]. Many facilities pay significant fees to transport the treated WAS (biosolid) to landfills. Transforming this waste into a resource to produce value added chemicals could have a positive impact on the cost of wastewater treatment for municipalities and industries.

Figure 1. Potential biobased chemicals and energy recovered from waste microbial matrices.

Figure 1. Potential biobased chemicals and energy recovered from waste microbial matrices.Biodiesel from raw activated sludge (RAS) and enhanced activated sludge (EAS)

Several investigators have demonstrated the use of WAS from municipal wastewater treatment plants as a feedstock for biodiesel production [13, 14, 15, 16, 17, 18, 19]. However, the biodiesel yield from RAS only ranges from 3 to 6 wt.% CDW (cell dry weight) [17], varying seasonally in amount and quality, and thus, making it an economically unattractive biodiesel feedstock option. Variation in yields as well as fatty acid profile due to the differences in wastewater treatment configurations and waste influent characteristics, could tremendously affect the properties of the resulting biodiesel [18].

Investigators discovered that biodiesel yield from activated sludge can be improved significantly by feeding the mixed consortium in WAS with excess carbon sources (substrate) while limiting the nitrogen content of the growth environment. Lignocellulosic biomass (particularly its sugar content) could be used as carbon sources for this process, that results in enhancement of the lipid content of activated sludge microbes [20], as shown in Figure 2. The enhancement increases lipid content of the activated sludge to as high as 47 wt.% CDW with a biodiesel yield of ∼20 wt.% CDW [12]. The resulting biodiesel has fatty acid profile similar to lard which at 20% blend (B20) has slightly higher viscosity, better oxidation stability, and higher cold filter plugging and cloud point compared to canola biodiesel B20 blend. A B10 blend has properties of the resulting fuel similar to those of soy biodiesel at the same blend [21•]. The enhancement also resulted in homogenization of fatty acid profile of the produced biodiesel [18,22]. Investigators fed WAS from several facilities with high C:N ratios, and basically the microbial ecology of the mixed consortium converges into an oleaginous consortium of lipid enhanced activated sludge (EAS). The increase in lipid yield could positively impact the LCA of WAS biodiesel [42]. Unmodified WAS requires relatively high methanol to sludge ratio, resulting in higher global warming impact potential compared to biodiesel from vegetable oil, beef tallow, and poultry fat. Thus, the integration of lignocellulosic biomass utilization and wastewater treatment operations could be a potential strategy for establishing urban biorefineries with improve environmental performance and economic feasibility.

Figure 2. Proposed WWTP concept for the enhancement of lipid and biodiesel yields from activated sludge.

Figure 2. Proposed WWTP concept for the enhancement of lipid and biodiesel yields from activated sludge.Green drilling fluids

RAS and EAS can also be used as additives in drilling fluids for lubrication and fluid loss reduction. Alternative additives characterized by low toxicity are gaining attention due to the stricter EPA’s regulation in drilling fluid disposal rules [23]. The combination of lipid and cellular materials in EAS such as phospholipids, glycoproteins, and amino acids can aid in lubrication. When extreme pressure is exerted on a drill bit, cell lysis of microorganisms could release lipids stored in the microorganism’s cell bodies, together with the cellular materials. Lubrication is achieved by forming a thin fluid film on the drill bit that separates the solid surface involved in drilling from the geological formation. The mechanism is demonstrated in Figure 3.

Figure 3. Mechanism of drilling fluid lubrication using microbial biomass.

Figure 3. Mechanism of drilling fluid lubrication using microbial biomass.RAS and EAS have been tested as drilling fluid additives in bentonite and baritemix water-based drilling fluids at concentration of 6.67 pounds per barrel. Two commercial products, fossil fuel-blend lubricant HDL PLUS lubricant (HDL+) and biological oil-based lubricant Bio Add 378A (BioAdd) were used as benchmarks [24••]. Results showed that friction reduction in RAS, EAS, HDL+ and BioAdd were 37%, 45%, 66%, and 74%, respectively. The higher lubricity in EAS compared to RAS was due to lipid content. Additionally, RAS is a more heterogeneous microbial community whereas the majority of EAS are oleaginous microbes. The heterogeneity of the microbial community may also affect the cellular materials contents, impacting the energy required for lysis of the cell wall and release of the lipids into the aqueous phase.

The fluid loss reduction shown in RAS, EAS, HDL+ and BioAdd were 1%, 10%, −7%, and 2%, respectively. The microbial biomass reduced the permeability in the drilling fluid, lowering fluid loss. High fluid loss in HDL+ and BioAdd could have been caused by foam formation. Generally, fluid loss reduction is not expected from commercial lubricants because they are designed solely for either application, not both, making RAS and EAS a dual-purpose additive, which could enhance the cost effectiveness of the materials.

Friction and fluid loss reductions are directly proportional to the lipid concentration in the microorganisms’ cell bodies. To achieve the same lubricating performance, higher RAS and EAS concentrations are required, compared to commercial additives. However, EAS and RAS could be used to replace costly and potentially environmentally harmful commercial additives, or in the alternate, could be used in conjunction with these synthetic additives, cutting down commercial additive consumption, reducing the cost of drilling, and further enhancing the value of WAS. One advantage of this application over the production of fuels from microbial extracted lipids is the use of the wet EAS. There is no need to dry the microbial mixture, which results in significant reduction in energy (e.g. drying) and operating (e.g. solvents recovery and purification) costs.

Corrosion inhibition applications

As mentioned above, growing WAS at high carbon:nitrogen ratio can enhance the lipid content and reduce the microbial diversity of the mixed consortium. This condition also favors EPS secretion. EPS are relatively high molecular weight mixtures of biopolymers, mainly made up of extracellular proteins, polysaccharides (carbohydrates), humic substances, uronic acid, and DNA. These are metabolic products synthesized by almost all microorganisms, which contribute to their slimy surface layers. They are generally used to protect the cells against the external environment and to serve as carbon and energy reserves during starvation.

EPS extracted from WAS microorganisms have been studied for various water treatment purposes [25, 26, 27]. Studies showed that EPS can effectively adsorb some heavy metal ions such as Zn2+ and Pb2+ in wastewater stream up to about 50% [25]. The adsorption mechanism is explained by two major functional groups in EPS: (1) the complexation between amino groups and heavy metal ions, and (2) ion-exchange between carboxyl groups and heavy metal ions.

It was hypothesized that the capability of EPS to adsorb metal ions could provide corrosion inhibition properties. Thus, the material was extracted and tested to inhibit corrosion of carbon steel using an environment that simulated oil field operations (3.64% of NaCl concentrated with CO2) [43••]. EPS is rich in nitrogen and oxygen compounds which are characteristic of high performing corrosion inhibitors. The compounds form protective biofilms on the metal surface to slow down corrosion rate as shown in Figure 4. The adsorption mechanism of EPS responsible for reducing the rate of electrochemical reactions on the metal surface is given by: (1) nitrogen and oxygen atoms acting as the polar heads of the inhibitor and adsorbing on the metal surface, (2) long hydrocarbon chains acting as the non-polar tails to isolate the metal surface from its corrosive environment. EPS corrosion inhibitor showed about 80% of corrosion inhibition performance when 1 g/L of inhibitor was applied. A study on the WAS extracted amino acids showed 88% inhibition in 10% HCl with 0.372 g/L of applied inhibitor [28,29]. The performances of WAS extracts are comparable to commercial products, which commonly show above 70% inhibition.

Figure 4. Adsorption of EPS on metal surface for corrosion inhibition.

Figure 4. Adsorption of EPS on metal surface for corrosion inhibition.Glues and composite materials

There is a constant push for more sustainable adhesives that are formaldehyde-free for the health and safety of particleboard manufacturers and consumers. Researchers have recently developed novel technologies for utilizing waste proteins from microalgae to make glues and adhesives [30,31•,32•]. They have been used to make particleboard composite materials by combining the algal glue with agricultural wastes (sugarcane bagasse) and forest product waste (sawdust). Mechanical testing has shown these materials (without the addition of formaldehyde) have Modulus of Rupture (Flexural Strength) values over 20 MPa and Modulus of Elasticity (Flexural Modulus) values over 2 GPa [30], exceeding the specifications for some MDF (medium density fiberboard) grades of particleboard.

In addition to being a VOC (volatile organic compounds)-free technology, adhesives can be made using a water-based denaturation process, which may require only a partial dewatering of the biomass, which makes the process highly cost-competitive. Also, these adhesives and composites represent a large-volume market, which is required to utilize the large amounts of biomass available. Some microbial biomasses from wastewater might be directly useful for making adhesives, but if the protein structure is not sufficiently intact to make a strong glue, then these waste streams may be used to grow microalgae, which is now known to make glues with marketable properties.

Biogas and organic acids

A technology used traditionally for the treatment of wastewater microbial biomass is anaerobic digestion [33], which is a naturally occurring process mediated by consortia of anaerobic microorganisms. The process produces biogas that typically contains high fraction of methane or hydrogen in addition to carbon dioxide and trace gases (sulfur-based and nitrogen-based) [34], as well as organic acids. Organic acids may be used as carbon-sources for platform chemicals by providing high carbon:nitrogen ratio environment [35•,36] to an aerobic chamber to generate EAS, and for fuels [14,22] and specialty chemicals production [35•,37•]. Organic acids can also be the substrates for an engineered anaerobic system that produces electrical power by implementing design principles of microbial fuel cell technology [38,39,40], which is a bioprocess technology that is actively researched. An increasing number of municipal wastewater facilities in the United States have gradually been installing and operating anaerobic digesters to recover biogas from waste sludges [44] following the practice gaining traction in Germany. The same trend is being observed in some European countries as well [45].

Other bioproducts

Several emerging technologies using WWTP sludges as feedstocks were presented in this paper. However, there are numerous other products that have been on the market or under development. Market-ready examples include renewable natural gas or RNG which is biogas from digesters with the CO2scrubbed from the gas generating almost pipeline quality natural gas [43••]. Biosolids after further disinfection, often via the adding of a base (NaOH or Ca(OH)2), sold as a low-grade agricultural fertilizer [46]. More evolving processes are thermal depolymerization into biocrude followed by refining into fuel cuts [47], extraction and purification of the proteins in WWTP sludges for use as animal feed supplements [46], thermal degradation of WWTP sludges (torrefaction, pyrolysis, gasification) to produce biochar, bio-oil, and syngas, and hydrothermal carbonization for biochar production [46,48,49], as well as the addition of biogas into aerobic chambers of WWTPs to convert the methane into lipids via methanotrophic microbial processes [50]. We envision that more products and process option will emerge, and more importantly, optimized over time to the point of full economic viability as the potential of WWTP sludges as industrial feedstocks into biorefineries emerge.

Conclusion

Microbial biomass could be foreseen as the feedstock for biobased chemicals and bioenergy of the future due to its versatility. The reliability of the cost and supply of this material also make it advantageous over foodcrops. Renewable fuels like biodiesel can be produced from microbial lipids in RAS and EAS. Specialty chemicals such as corrosion inhibitors and adhesives can be manufactured using the remaining parts of the microbial biomass. The versatility of products could positively transform the economic and environmental sustainability of biorefineries. Envisioning and implementing these concepts to wastewater treatment facilities could completely change the economic model of these operations and repurpose them as resource recovery and profit centers within municipalities. The ultimate goal of green technologies is the reduction fossil fuel dependence. The recovery of valuable resources from other waste sources could be extended to other systems, contributing to the enhancement of the feasibility of the green economy.