1. Introduction

Non-centrifugal cane sugar (NCS) is the technical term used by the Food and Agriculture Organization of the United Nations (FAO, 1994), for a traditional minimally processed sweetener from sugar cane (Saccharum officinarum L.). It is a solid unrefined product with a unique flavor and aroma, obtained by evaporating sugarcane juice. Sucrose is the most important component (65–85%), followed by reducing sugars (10–15%), water (3–10%) and insoluble matter such as fat, proteins, minerals, iron and phosphorus (<1%) (Rupe, 2007). Its main use in regions such as Asia, Africa, Latin America and the Caribbean is as a sweetener, and its importance lies in its traditional characteristic flavor and nutritional value (Pawar and Dongare, 2001, Sahu and Paul, 1998, Singh, 2001, Singh et al., 2008). However, various medicinal attributes have been reported (Harish Nayaka et al., 2009, Pattnayak and Misra, 2004, Sahu and Paul, 1998, Sahu and Saxena, 1994, Singh et al., 2008). According to the region where it is produced, it receives different names. In Latin American countries it is known as panela (Colombia, Guatemala, Panama, Ecuador, Bolivia), papelón (Venezuela), rapadura (Brazil, Argentina), raspadura (Dominican Republic, Ecuador), chancaca (Peru, Chile), piloncillo (Mexico), tapa dulce (Costa Rica), atado de dulce (Nicaragua), and empalizado (Bolivia), while in Asian countries it receives the names of jaggery, muscovado and kokuto (India, Philippines, Japan, respectively) (Jaffé, 2012a, Jaffé, 2012b).

NCS is a product with high sucrose content that consists of irregularly shaped anhydrous microcrystals surrounded by various constituents such as reducing sugars, minerals, vitamins, amino acids and other traces (WCO, 2012). Jaffé (2015) reported the different nutritional and bioactive components present in NCS in producing countries such as Bangladesh, Brazil, Central America, Colombia, Japan, Peru, and UK. There is a high variation in the NCS components content even at a regional scale.

NCS can be considered as a potential bioactive product, with antioxidant activity (AO) attributed mainly to the retention of a large amount of phenolic and flavonoids compounds of sugar cane juice (Asikin et al., 2016, Harish Nayaka et al., 2009, Meerod et al., 2018, Okabe et al., 2008, Payet et al., 2005, Seguí et al., 2015, Weerawatanakorn et al., 2016) which in turn are responsible for the development of NCS aroma and color profiles (Lee et al., 2018). NCS have higher contents of phenolic and flavonoid compounds compared to white and brown cane sugars (Table 1). Furthermore, NCS has the highest content of policosanol and long-chain aldehyde which are components that may have beneficial effects on human health (Asikin et al., 2012, Weerawatanakorn et al., 2016).

Table 1. Phenolic and flavonoid content in products from sugarcane.

| Phenol content (Gallic Acid Equivalents μg/g) | Flavonoid content (quercetin equivalents μg/g) | Reference | ||||

|---|---|---|---|---|---|---|

| White sugar | Brown sugar | NCS | White sugar | Brown sugar | NCS | |

| 26.5–31.5 | 372 | 3837 | – | – | – | Harish Nayaka et al. (2009) |

| – | 108.1–418.1 | – | – | – | – | Payet et al. (2005) |

| – | – | 3096–4517 | – | – | – | (Inafuku et al., 2007) |

| 0 | 371–546 | 100–2620 | 22 | 690–1893 | 1590–6150 | Seguí et al. (2015) |

| – | – | 2105–2642 | – | – | – | Asikin et al. (2016) |

| – | – | 10867–14832 | – | – | (77.81–95.61) a | Meerod et al. (2018) |

| – | – | 2330–13950 | – | – | (0.03–2.09) b | Weerawatanakorn et al. (2016) |

- a

-

Value expressed as mg RUE/100 g.

- b

-

Value expressed as mg RAE/g.

The nutritional content and AO of NCS has given way to the study of the potential effect on human health. In this aspect, Harish Nayaka et al., (2009)showed that NCS has a 97% protection against the oxidation of NIH 373 cells (concentration 4 mg/ml) compared to brown sugar, effectively reducing the oxidation of erythrocytes. In addition, protection against DNA damage induced by hydroxyl radicals was evident (Harish Nayaka et al., 2009). Similarly, N. Singh et al., 2008, showed that the bioactive components of NCS (iron and vitamin C) are effective in reducing the frequency of chromosomal aberrations by inhibiting the toxic mechanism of arsenic, so that the consumption of NCS can be taken as a preventive measure against the arsenic-induced toxicity in affected populations.

The range of nutritional components, bioactive and the sensory profile of NCS is influenced by the agronomic conditions (genotypes of cane, soil types, fertilization, harvest, among others) and the conditions of industrial processing (thermal treatments) (Jaffé, 2015). Therefore, the quality in NCS is inherent to the cultural practices of harvest, transformation and finished product in each producing region and country.

In NCS safety issues, the presence of chromium (Iqbal et al., 2017) and acrylamide (Vargas Lasso et al., 2014) have been reported, which are a consequence of the harvest stage and transformation respectively. Studies have found that acrylamide exposure increases the risk for several types of cancer (Dearfield et al., 1988, Lipworth et al., 2012, National Toxicology Program, 2012, Virk-Baker et al., 2014). In the body, acrylamide is converted in glycidamide, which causes DNA damage. However, epidemiological studies (both case-control and cohort studies) in humans have found no consistent evidence that dietary acrylamide exposure is associated with the risk of any type of cancer (Lipworth et al., 2012, Virk-Baker et al., 2014).

Colombia is the largest NCS consumer per capita worldwide with an average of 24 kg/year (Osorio Cadavid, 2007), and is the second largest producer after India, i.e. producing 1.388.554 t and generating 287.500 jobs (Mendieta et al., 2016). This gives a clear view of the socioeconomic importance of the NCS agribusiness in agricultural production. Nevertheless, there are several problems that affect its competitiveness, quality and sustainability in rural areas. Currently, NCS production systems do not have the capacity to meet the demand and quality requirements of national and international markets (Flórez Martínez, 2013). Therefore, efforts in the productive sector of NCS should be focused on increasing production by strengthening each of the links that make up the chain.

NCS production modules (NCS-PM) are mainly comprised of operational units that largely involves:

-

•

Juice extraction through a milling process.

-

•

Water evaporation and juice concentration with the purpose to obtain the syrup, where the thermal energy is obtained in the furnace.

-

•

The syrup is crystallized by mechanical agitation at temperatures between 115 and 120 °C and molding to solid shape.

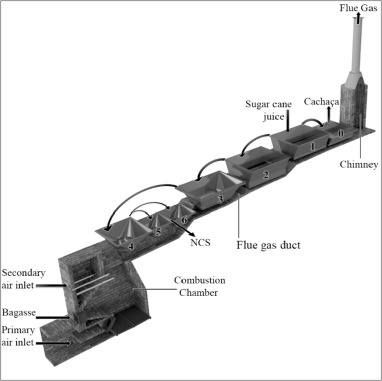

Fig. 1 shows the structure of a NCS-PM. Obtaining NCS is done by the open evaporation method (Tiwari et al., 2004). In the combustion chamber, the energy necessary for the transformation of cane juice is obtained from the combustion of sugarcane bagasse. Flue gases obtained in the thermochemical conversion process by the combustion of bagasse are displaced by the effect of the draft generated in the chimney through the gas pipeline and transfer the thermal energy to the open heat exchangers or pans. In these, the water is evaporated from the juice until NCS is obtained.

Fig. 1. Structure of a PM-NCS. Thermal stages: clarification (0–1), evaporation (2–4) and concentration (5–6).

Fig. 1. Structure of a PM-NCS. Thermal stages: clarification (0–1), evaporation (2–4) and concentration (5–6).The production diagram of a NCS-PM is shown in Fig. 2. The process begins with the extraction of sugarcane juice in roller mills, which are manually fed. Subsequently, the juice is transported to the evaporation system (Fig. 1). Three thermal stages are differentiated during the evaporation process: clarification (pans 0 and 1), evaporation (2–4) and concentration (pans 5 and 6). In the clarification stage, the increase in juice temperature together with the addition of vegetable flocculating agents, allows the removal of impurities from the juice (Rodríguez et al., 2018). In the evaporation stage, the heat supplied is used in the phase-change of the water (from liquid to vapor) and sugar concentration increases from 22 ± 2 °Brix to 60 ± 10 °Brix. Finally, the concentration stage evaporates the water to a concentration of 92 ± 4 °Brix to obtain NCS (Rodríguez et al., 2018).

Fig. 2. Production diagram of a NCS-PM.

Fig. 2. Production diagram of a NCS-PM.However, in the production of NCS, the energy efficiency of the process and final components depend to the type of technology implemented (La Madrid et al., 2016, Rodríguez et al., 2018, Prada Forero et al., 2015). Several characteristics of the NCS are dependent on each of the procedures that make up the production chain, from the supply to the manufacturing process and subsequent commercialization. For this reason, it is necessary to increase efforts in using appropriate technologies and optimal operation conditions, mainly as a result of a growing concern with food quality and food safety (Van Der Vorst, 2006). Therefore, the objective of this study is to provide a comprehensive view of the NCS production chain and the variables that affect the different characteristics of the product. We analyzed the different variables in the manufacturing process and identified what influences the NCS composition, physical characteristics and yield.

2. Variables related to NCS production and their effect on quality

In this section, the literature review of the variables related to the NCS production as well as their effects on production are showed. In appendix A, we show the literature analyzed in this study and classified it in a matrix that relates the variables related to the process and its influence on the final product quality and food safety of the NCS.

2.1. Cultivar

For NCS and sugar production, sugarcane varieties with high sucrose content are used. Table 2 shows the content of sucrose, reducing sugars and total soluble solids of some varieties of India and Colombia. Harvesting age, sugarcane varieties, and different pre-seasonal planting conditions influence the NCS quality in terms of color, pH, reducing sugars and sucrose content (Jadhav et al., 2000, Virginia Mujica et al., 2008). However, varieties can significantly affect the operating conditions and final product quality (Singh et al., 2000, Weerawatanakorn et al., 2016). Virginia Mujica et al. (2008) reports that the influence of two varieties (Puerto Rico 61632 y Mayari 5514) significantly affected the content of reducing sugars, color and pH in NCS products. Similarly, Uppal et al. (2005) evaluated the impact on NCS quality of 16 sugarcane varieties, and showed that CoJ 82 and CoP 211 provided the best sensory attributes regarding color in NCS. Asikin et al. (2012) and Weerawatanakorn et al. (2016) indicated that the composition and wax, policosanol and long-chain aldehydes contents may vary depending on the cultivar of the sugarcane.

Table 2. Content of sucrose, reducing sugars and total soluble solids of some sugarcane varieties.

| Genotype | Sucrose (%) | Reducing sugars (%) | Total soluble solids (° Brix) | Reference |

|---|---|---|---|---|

| CoP (211, 90223), CoJ 89 | 17.23–17.91 | 0.12–0.29 | – | Uppal et al. (2005) |

| CoJ (64, 86), CoS 96258, Co 1148, S 3/93 | 18.25–18.87 | 0.13–0.24 | – | |

| CoJ (82, 83, 84), CoS (8436, 95255), S 362/95 | 19.01–19.33 | 0.09–0.22 | – | |

| CoJ (85, 88) | 20.10–20.27 | 0.07–0.16 | – | |

| SNK (71334, 71342, 7183, 7685, 7866) | 16.81–18.90 | – | 17.83–19.63 | Guddadamath et al. (2014) |

| SNK (7056, 71138, 71206, 7337, 7344, 7664, 71208) | 19.17–19.97 | – | 20.03–20.77 | |

| SNK (7156, 7356, 7342, 7360, 7680) | 20.45–20.95 | – | 20.87–21.57 | |

| SNK (71013, 7665, 7810) | 21.11–21.28 | – | 21.63–21.91 | |

| CC (01–1305, 91–1555) | 16.9–17.2 | 1.3–2.3 | 18.6–19.7 | (Insuasty Burbano et al., 2003; Ramírez Durán et al., 2014) |

| CCSP 89–43, CC (85–47, 85–92, 99–1405, 92–2965, 937711), CP 57–603, RD 75–11, | 18.2–18.8 | 0.46–1.0 | 19.9–21 | |

| CC (00–2639, 01–678, 86–45, 88–439, 92–2154, 92–2198) | 19.2–19.8 | 0.59–1.1 | 20.0–20.8 | |

| CC (84–75, 85–57, 93–3458, 93–714, 93–7510) | 20.0–20.9 | 0.51–1.0 | 21.3–22.4 | |

| SP50 | – | – | 17.31 ± 0.01 | Weerawatanakorn et al. (2016) |

| UT12 | – | – | 17.83 ± 0.01 | |

| KK3 | – | – | 18.10 ± 0.01 | |

| SRS2 | – | – | 18.01 ± 0.01 | |

| TP | – | – | 18.46 ± 0.01 |

In India the varieties of sugarcane hybrid clones most cultivated to produce NCS are SNK07337, SNK 0680 and Co 92005 (Guddadamath et al., 2014). While in Colombia are RD 75–11, POJ 2878, CP 57–603 and CC 93–7711. For NCS production the use of different sugarcane cultivars is advised in order to optimize the physical and chemical properties of the final product, including the polyphenols and antioxidant contents (Jaffé, 2015).

2.2. Storing

Usually in all NCS producer countries harvested sugarcane is stored in the field or in production units, that if stored for prolonged periods, it influences directly sugarcane juice quality. Sugarcane quality decreases with time, i.e. starting immediately after cutting and continuous during transport, storage and milling operations (Solomon, 2000). Therefore, no extended sugarcane storage time after harvest has been recommended. Several authors have reported the generation of certain substances during the deterioration process of sugarcane (Eggleston, 2001, Lionnet, 1986, Morel, 1995, Solomon et al., 2006), including invert sugars, polysaccharides and microbial contamination (e.g. with Leuconostoc spp.). The rate of quality loss depends on environmental conditions, sugarcane variety and the management system used.

Nonetheless, different studies show some approaches to reduce sucrose losses after harvest. Singh et al. (2006) formulated treatments based on the addition of an effective biocide (sodium azide 1% w/v) and heating of the juice (100 °C for 2 min) to destroy all microorganisms and inactivate the acid invertase present in the juice. Reducing sugars and the specific activity of the acid invertase were significantly lower in juice treated with biocide compared to the untreated control (Singh et al., 2006). Solomon et al. (2006) found that pre-harvest foliar application of divalent cations (Zn++ and Mn++) and post-harvest application of anti-bacterial formulations decrease sucrose loss rate after harvest.

2.3. Juice extraction

Sugarcane juice extraction is carried out through a milling operation that takes place after storage, in which the water and dissolved sugars contained in the sugarcane are removed. The goal of the extraction process is to remove the maximum juice amount present in the sugarcane and at the same time, produce bagasse with suitable moisture content to be burn in biomass or bagasse boilers.

Juice extraction can be obtained in principle by compression of whole or cut sugar cane stalks or by diffusion of the juice from ruptured stalk (bagasse) tissues and cells. We have only identified one case where diffusion was used in NCS production (Jaffé, 2012a, Jaffé, 2012b).

In the traditional NCS processing a dry extraction process is carried out, i.e. the milling process is carried out without the addition of water. Generally, a horizontal three-roller crusher is used. This type of mill is the most widespread in the NCS production industry. Unlike the vertical mills that have an extraction efficiency between 50 and 55%, the horizontal mills have an efficiency of 55–60%. Therefore, their use is more frequent (Oliveros Donohue, 2014, Rao et al., 2007). Likewise, in the sugar industry, the same crushing technique is used, however, the crushing is done in multiple mills with the addition of hot water, where the process efficiency ranges between 77 and 80% (Birru, 2016).

Horizontal mills have their maces placed horizontally in a triangular distribution, and in the industry, most are 3 fluted rollers and some few are 5 fluted rollers. Corporación Colombiana de Investigación Agropecuaria (Agrosavia) developed a design with two mills, each being 3 fluted rollers in series obtaining 70 kg of juice per 100 kg of sugarcane (García et al., 2007).

2.4. Bagasse combustion to produce energy

The thermal energy for heating to generate water evaporation and the elaboration of NCS is obtained from sugarcane bagasse through the thermochemical combustion process in fixed bed ovens. According to Navarrete Cereijo et al. (2017), the industrial design of biomass burners requires optimum understanding of the different phenomena that occur during biomass particle combustion (heating, drying, pyrolysis, combustion of volatile particles and char combustion) (Spliethoff, 2010). Biomass combustion is a complex process that simultaneously involves fluid flow, chemical reactions and mass and heat transfer (Silva et al., 2017).

Two types of fixed-bed combustion chambers in NCS traditional production modules have been reported in the literature: flat and Ward chambers (La Madrid et al., 2016, La Madrid et al., 2017, Rodríguez et al., 2018). The flat chamber design is the most frequently used in NCS-PM. It is generally characterized by being located inside the gas pipeline. It is a rectangular section with a limited reaction volume consisting of one inlet for fuel supply and another for the primary combustion air inlet. However, this design has been made empirically without including theoretical aspects and mathematical models for bagasse combustion (Sánchez Castro and Mendieta Menjura, 2014). A common problem this chamber has is the design of the fuel bed, where the processes of drying, devolatilization and oxidation of the char occurs irregularly along the grate. As a result, volatile formation is uneven and enriched areas of volatile fuel are generated making it impossible for the air to completely oxidize before they are released from the combustion zone. Therefore, low combustion temperatures (ca. 650–850 °C, dry bagasse 30% w.b.), inadequate residence times (short or prolonged), high carbon monoxide (CO) emission rates (5%) and higher specific fuel consumption are obtained (Ariza et al., 1992, Rodríguez et al., 2018).

Nevertheless, simulating the process as a design tool has allowed to generate improved designs such as the Ward-Cimpa camera (Forero et al., 2012, Sánchez Castro and Mendieta Menjura, 2014). Unlike the flat chamber, it has a reaction volume four times larger, its design considers a pre-drying ramp, a primary combustion zone in a fixed bed and secondary air inlets in the upper part of the bed for the reaction of volatiles and unburned material (Sánchez Castro and Mendieta Menjura, 2014). This design allows releasing higher heat rates reaching combustion temperatures between 850 and 1200 °C with bagasse humidity between 55 and 15% (w.b.), respectively. Furthermore, it also decreases CO emissions to 1% (Ariza et al., 1992, Guevara Enciso, 2014, Rodríguez et al., 2018), allowing a significant increase in the thermal efficiency of the process.

Experimental investigations of this type of systems show difficulties due to limited access and lack of homogeneity within the bed (Karim and Naser, 2017). Therefore, in this type of furnaces, the computational fluid dynamics (CFD) is an effective tool for a better understanding of the thermal phenomenon of biomass conversion and optimization of the combustion process (Gómez et al., 2015). The CFD modeling techniques have allowed to analyze the performance of thermochemical conversion equipment, predicting variables such as fluid flow behavior, heat-mass transfer (e.g. devolatilization and combustion), phase changes, among others (Wang and Yan, 2008). From these studies, it is possible to establish that an adequate proportion in the primary and secondary air supply, as well as a higher injection speed in the latter, contributes to improve the rate of heat release in the combustion process and decreases the rates of carbon monoxide emission. These results have positive environmental impacts as they decrease specific combustion use and other sources of polluting fuels as carbon and tires, reducing on one hand CO, CO2, NOx, SOx, particulate matter, and avoiding on the other hand, deforestation in rural areas.

2.5. Thermal process

The evaporation process of sugarcane juice can be divided into three thermal stages: clarification, evaporation and concentration (Rodríguez et al., 2018). The overall thermal efficiency of the process depends on one hand on the capacity of the combustion systems to supply the thermal power, and on the other hand, on the heat exchangers to take advantage of the maximum thermal energy of the flue gases to evaporate the water from the juice. The heat transfer systems used for juice evaporation in traditional NCS-PM are open evaporators or pans.

The geometric configurations of the pans used for the production of NCS (see Fig. 3) vary according to the thermal stage of the process. Pyrotubular, flat (Fig. 3a) or grooved pans (Fig. 3c) with or without fins (Fig. 3b) are mainly used for clarification and evaporation processes, while semi-cylindrical (Fig. 3d) or semispherical pans (Fig. 3e) are suitable for sugarcane juice concentration and evaporation processes (La Madrid et al., 2017, Rodríguez et al., 2018).

Fig. 3. Open pans in traditional PM-NCS: (a) Pyrotubular, (b) flat with fins, (c) Grooved, (d) Semi cylindrical and (e) Semispherical.

Fig. 3. Open pans in traditional PM-NCS: (a) Pyrotubular, (b) flat with fins, (c) Grooved, (d) Semi cylindrical and (e) Semispherical.Different temperature profiles that are developed in each of the exchangers during the evaporation process, affects the change of juice properties such as color (García et al., 2017), bioactive components (Lee et al., 2018), viscosity, density, thermal conductivity, and specific heat (Jagannadha Rao et al., 2009). The application of thermal treatments produces the darkening of the juice, which is explained by the gradual formation of melanoidins (dark colored compounds) through caramelization and Maillard reactions (Tomasik et al., 1989). At temperatures below 50 °C enzymatic browning (oxidation of phenolic components) occurs and above this temperature the enzymatic activity stops, but the darkening continues up to the temperature at which NCS is obtained (Banerji et al., 2012).

The study presented by Banerji et al. (2012) showed the development of NCS color through the caramelization of sucrose, glucose and fructose in the manufacturing process at pH < 6 and temperature between 116 and 118 °C. However, fructose caramelization at 118 °C contributes mostly to the development of color in NCS compared to glucose and sucrose. Likewise, García et al. (2017) reported that the color parameter in NCS-based beverages depends to a large extent on the heating system used during NCS processing due to the influence of the Maillard reactions that take place during the evaporation of sugarcane juice. Therefore, the thermal stage is the most relevant in the production process, since it determines the final product quality.

2.5.1. Juice cleaning and clarification

The juice obtained from the milling process is decanted to remove bagasse particles and other materials suspended in it. For this operation, pre-cleaning equipment or filters are used. Later the juice is stored in decanting tanks for a previous cleaning through the physical settlement of coarse and heavy impurities, as it is described for the cases of India and Colombia (Rao et al., 2007, Rodríguez et al., 2007).

Storage is carried out under ambient conditions (24–34 °C), and during this period the juice must be clarified. A prolonged residence time of the juice during this stage, favors enzymatic action and oxidation of some of its components (especially chlorophyll and polyphenols, among others) producing a darkening of the juice and thus, it can negatively affect the final quality (Prati and Moretti, 2010). The clarification process involves heating, changing the pH and using synthetic or natural clarifiers/flocculants. The use of these physical means and changes of the chemical parameters of the juice allow the coagulation and trapping of proteins, lipids, waxes and gums in the juice (Azeredo Cesar and Cesar Da Silva, 2009, Mendonça do Nascimento, 2007). Since juice is a complex colloidal system, where solid particles have different isoelectric points, simple decantation without any physical or chemical treatment is not a viable option. In addition, coagulation, flocculation and precipitation phenomena of solid particles in the juice governs the clarification process. When these processes have been carried out by joint action of the thermal and chemical treatments, solids are eliminated by decantation and filtration, i.e. an insoluble precipitate that absorbs and drags such compounds from the juice when it is formed.

Agronomic management and maturity state of the sugarcane has an effect on the pH of the juices (Mendieta et al., 2016). The addition of pH regulators and their incidence on sucrose glycolysis has been studied by Prada Forero et al. (2015). This study showed that an increase in pH (≥6.0) in sugarcane juice causes a marked darkening of NCS (Prada Forero et al., 2015). Regarding coagulation, an alkaline medium must be guaranteed using agents such as calcium oxide (quicklime), sodium hydroxide (slaked lime), sodium carbonate, sodium hydrosulfite and sodium bisulfite; however, these last two are prohibited (Quezada Moreno, 2012). The alkalizing agents are usually dissolved in small amounts of water and added to the pan at the boiling point. The addition of the reagents modifies the pH of the juice and with temperature precipitates are formed, eliminating impurities (Koblitz, 1998). Consequently, particles are flocculated on the surface of the juice during boiling forming a foam, which is removed using physical means such as ladles, fine meshes or passing a thin cotton cloth through the juice.

Among the main clarifying plant-based agents used in countries such as India are: Hibiscus figulneus, Hibiscus esculentus, Bombus malbaricum, Kydia calycina. Whereas in Latin America we found Heliocarpus appendiculatus (“Burrio”), Heliocarpus americanus, Heliocarpus popayanensis, Triunpheta lappula (“Cadillo”), Gauzuma ulmifoliase (“Guacimo), Pavonia sepium (“Balso”) Ricinus communis and Guazuma ulmifolia (Funach, 2002, Mendonça do Nascimento, 2007, Ortiz G et al., 2011, Quezada Moreno, 2012). The mucilage of these plants is extracted by maceration and diluted with their bark water (Funach-Ascapam, 2002). The mechanism of action of these natural clarifiers in coagulation and flocculation processes has not been determined.

2.5.2. Juice evaporation

Once the juice has been clarified, it is transported to the evaporation stage. At this stage, the sugarcane juice is concentrated in syrup, i.e. the concentration of total soluble solids (sugars) changes from 22 ± 2 °Brix to 60 ± 10 kg NCS/kg juice. The evaporation and concentration are the main thermal stages of NCS production, where 80% of the water of the sugarcane juice is removed. However, low thermal efficiency has been reported in these stages, hence, several studies have been developed to improve the thermal performance of NCS-PM.

Authors as Jakkamputi and Mandapati (2016) carried out tests with solar collectors in order to supply the sensible heat required to raise the temperature of the sugarcane juice to its boiling point, obtaining fuel savings of 0.24 kg bagasse/kg NCS. Likewise, they studied the use of a solar dryer to supply hot air to the combustion chamber, in order to improve the efficiency of the process, generating savings of 0.12 kg bagasse/kg NCS.

Anwar (2010) made improvements in the heat exchanger of flat bottom through the implementation of fins. This helped to improve the heat transfer to sugarcane juice increasing the efficiency of heat use by 9.44% and saving 31.34% of fuel. Rane and Uphade (2016) presented a method to improve the juice quality. They implemented an improved freezing pre-concentration system that uses a reversible heat pump for the manufacture of NCS. Quality of NCS is improved by reducing sugarcane juice exposure (from 20 °Brix to 40 °Brix) to low temperature, generating a water removal of 63%.

CFD models have been used as a numerical tool to predict and improve the thermal performance of NCS-PM. La Madrid et al. (2017) designed a pyrotubular pan, which could replace a flapped flat pan using a CFD model as a numerical tool. The results of the study showed that for the heating, clarification and evaporation processes, the thermal energy used increased significantly. Thus, the overall thermal efficiency of the production process increased from 31.4% to 42.8%, and an increase of 25% was estimated for the NCS production.

In the same way, the CFD tools have allowed to define temperature profiles and heat transfer mechanisms along the flue gas pipeline. In this aspect, La Madrid et al. (2016) established the heat transfer rate of the combustion gases to sugarcane juice in the NCS-PM considering two cases: 1) adiabatic walls without including thermal radiation phenomena, and 2) linear temperature profile along the flue pipe walls including the thermal radiation model P-1. The results of the study allow the establishment of the predominant heat transfer mechanism along the combustion gas pipeline and, in addition, it allows to validate if the CFD tool is appropriate for the NCS-PM design.

Based on this last study, it is possible to modify and distribute the heat exchangers along the pipeline. This allows to take advantage of the heat coming from the flue gases, increase the thermal efficiency of the process and ensure the physicochemical and organoleptic quality of the juice.