1. Introduction

Cryogenics is the science of production and application of artificial cold at very low temperatures. For a long time, the temperature range of cryogenics was not strictly defined, until the 13th IIR International Congress of Refrigeration (held in Washington DC in 1971) adopted a universal definition of “cryogenics” and “cryogenic” by accepting a threshold of 120 K to distinguish these notions from conventional refrigeration [1]. This is a rather reasonable temperature limit because of the normal boiling points of the most important working substances in the cryogenic industry (including helium, hydrogen, nitrogen, oxygen, and air) all lie below 120 K. For comparison, the refrigerants commonly used in conventional refrigeration applications, such as domestic refrigerators, air conditioners, and freezers boil at temperatures above 120 K at atmospheric pressure.

Heat exchangers are among the principal components of cryogenic systems. To achieve good overall energy performance of the system, which is mostly determined by the energy requirements of the compressors, cryogenic heat exchangers should be designed to operate at relatively small temperature differences. This requires large heat transfer areas and thus bulky equipment with high initial cost [2]. High effectiveness is necessary for such heat exchangers to be cost-efficient. It has been demonstrated that a 1% increase in the effectiveness of a cryogenic heat exchanger, used in an air separation plant, decreases the compressor power consumption by 5% [3].

Cryogenic heat transfer occurs in a variety of process applications [4]. High-performance heat exchangers are essential for air separation systems which are used to produce liquid nitrogen, liquid oxygen, and liquid argon. There, recuperative heat exchangers are employed to pre-cool the incoming warm air stream by the outgoing cold gas stream, reducing the need for external refrigeration [5]. The effectiveness of those heat exchangers must be approximately 95% or higher for the system to operate economically.

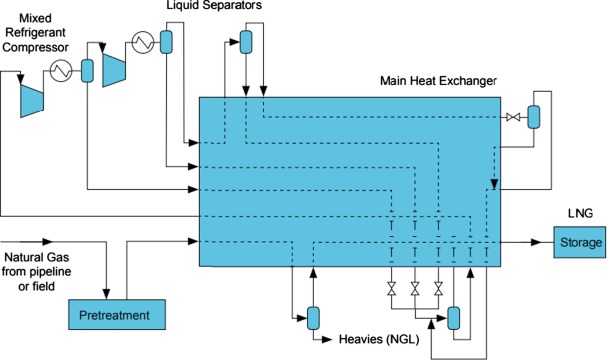

The industrial applications of cryogenic technologies can be summarised in three categories: (1) process cooling; (2) separation and distillation of gas mixtures; and (3) liquefaction for transportation and storage [6]. The cryogenic industry has experienced continuous growth in the last decades, which was mostly driven by the worldwide development of liquefied natural gas (LNG) projects. The LNG technology provides an economically feasible way of transporting natural gas over long distances and currently accounts for nearly 30% of the international trade of this resource. Natural gas liquefaction requires large cryogenic heat exchangers, where natural gas is cooled, liquefied and subcooled to 111 K. Some liquefaction cycles utilize separate heat exchangers to perform the precooling or subcooling duty, while others may require only a single multi-stream heat exchanger per production train, commonly referred to as main heat exchanger. The economic feasibility of many LNG projects, considering the associated capital and operating costs, is to a large extent controlled by the performance of the main cryogenic heat exchanger. The liquefaction process presented in Fig. 1 involves such an apparatus. It is incorporated in a mixed refrigerant closed-loop cycle, using a mixture of hydrocarbons and nitrogen [7]. The refrigerant is compressed and separated into liquid and gaseous streams. The lightest fractions of the refrigerant are directed to the cold end of the main heat exchanger, cooled and sent back to the compressors, after being vaporized through the main heat exchanger. The heaviest fractions are let down and vaporized at an intermediate level also in the main heat exchanger. The advantage of the mixed refrigerant cycle is the employment of the vaporization temperature difference between the generated refrigerant streams to optimize the NG liquefaction heat exchange profile.

Fig. 1. Process flow diagram of natural gas liquefaction unit (courtesy Air Liquide [7]).

Fig. 1. Process flow diagram of natural gas liquefaction unit (courtesy Air Liquide [7]).Liquefaction shrinks the volume of the gas almost 600 times, making it easier and safer to store and ship. Once delivered, it is converted back into gas at re-gasification facilities, usually involving large heat exchangers again.

Another industrial application of cryogenics, called Liquid Air Energy Storage (LAES), has been recently proposed and tested by Morgan et al. [8]. LAES systems can be used for large-scale energy storage in the power grid, especially when an industrial facility with high refrigeration load is available on-site. LAES systems can help accommodate the increasing proportion of renewables in the energy supply mix by compensating for the mismatch between the periods when the availability of renewable energy is high and the periods of high energy demand in the power grid [6]. LAES involves three core processes: (1) system charging; (2) energy storage; and (3) power recovery (also referred to as discharging), as shown in Fig. 2. Charging is done by a liquefier, which uses electricity, e.g., power generated from renewable sources integrated into the grid, to draw air from the surrounding environment, purify it and then cool it to cryogenic temperatures until it liquefies. The liquid air is then stored in an insulated tank at low pressure. When power is required, liquid air is drawn from the tank and pumped to high pressure. The air is evaporated and superheated to ambient temperature. This produces a high-pressure gas, which is used to drive an air turbine, thereby providing power to the grid. LAES is prone to easy integration with important industrial technologies, such as refrigerated warehousing of food and pharmaceuticals [6]. The LAES technology has many similarities with air separation and natural gas liquefaction. The use of high-performance cryogenic heat exchangers is also an essential prerequisite for this promising energy storage technology.

Fig. 2. Process flow diagram of liquid air energy storage plant (Sciacovelli et al. [9]).

Fig. 2. Process flow diagram of liquid air energy storage plant (Sciacovelli et al. [9]).Another recent application of cryogenics involves carbon (as CO2) capture. It is a post-combustion technology that cools the flue gas of a fossil fuel power plant to de-sublimation temperatures (173–138 K), separates the generated solid CO2from the light gaseous components, uses the cold products to cool the incoming gases in a recuperative heat exchanger, compresses the solid/liquid CO2 to final pressures (100–200 bar), and delivers the compressed CO2 stream ready for storage (Fig. 3).

Fig. 3. Process flow diagram of the cryogenic carbon capture (Baxter et al. [10]).

Fig. 3. Process flow diagram of the cryogenic carbon capture (Baxter et al. [10]).According to Baxter et al. [10], this CO2 capture technology is very promising, as the overall costs seem to be at least 30% lower than most competing processesthat involve air separation units (ASUs), solvents, or similar technologies. Cryogenic technologies are also gaining ground in transport refrigeration, particularly with the Dearman engine. This is a liquid-nitrogen-powered piston engine, which is used to both move and cool the vehicle [6].

The presented brief overview of the current large-scale cryogenic technologies clearly indicates the critical and expanding role of cryogenic heat exchangers. Such heat exchangers are operated under demanding conditions, which include: large temperature range, multiple streams, multi-component mixtures and flow injection and removal. Therefore, many design aspects, which are not considered in the design of conventional heat exchangers, need to be taken into account in the design of cryogenic heat exchangers. As revealed by Pacio and Dorao, cryogenic heat exchangers have traditionally been designed and rated using three types of models: lumped parameter, distributed parameter and stream evolution [11]. Various studies have also employed computational fluid dynamics (CFD) modelling to optimize the design of cryogenic HEs or to obtain empirical coefficients for simpler models, as discussed in the sections below. In addition, the unique modelling challenges presented by multi-stream heat exchangers (MHE), especially when multiple phases are involved, have led to the development of new modelling methods based on pinch analysis. A general classification of the models is given in Fig. 4.

Fig. 4. Types of heat exchanger models (Pacio [2]).

Fig. 4. Types of heat exchanger models (Pacio [2]).Lumped parameter models are the most common and represent the basic design theory for heat exchangers. The basic differential equations, describing the energy balance of the heat exchanger, are integrated over the whole heat exchange surface area by applying the following assumptions: (1) steady-state operating conditions; (2) no heat transfer with the surroundings; (3) negligible longitudinal heat conduction; (4) constant overall heat transfer coefficient and constant heat capacities of the fluids. Therefore, lumped parameter models neglect some effects which are irrelevant to the typically required engineering precision [3].

However, the high-effectiveness requirements for cryogenic HEs necessitate consideration of the changes in fluid properties, heat exchange with the surroundings, longitudinal thermal conduction in the wall, flow maldistributionand combined effects, as reported by Pacio and Dorao [11]. The distributed parameter and stream evolution models can take these effects into account. Distributed parameter models are based on dividing the heat exchanger into elements of variable size and applying a lumped parameter model to each of them. Stream evolution models are based on steady-state one-dimensional mass, momentum, and energy balance equations for each stream. These models are usually implemented in proprietary software. Among their key features are the correlations used for determining the fluid properties and heat transfer and pressure drop characteristics.

More detailed analyses of the fluid dynamics and heat transfer processes in the flow passages of the heat exchangers can be accomplished with CFD models. They are based on discretization of the space domain into a two or three-dimensional mesh of finite volumes or elements and a coupled numerical solution of the continuity, momentum (Navier-Stokes) and energy equations applied to each volume (element). Nevertheless, CFD models require large amounts of time and effort, restricting their use primarily to the area of research and development.

MHEs are common in cryogenic applications, such as natural gas liquefaction systems, where the streams can be both multicomponent and multiphase [12]. These are very difficult to model which has motivated a number of recent studies to develop new approaches, borrowing techniques from pinch analysis. Kamath et al. [13] propose such a model with special emphasis on handling phase transitions. They demonstrate its capability in two case studies of cryogenic applications. Further work concerning the same model is done by Holene [14]. Other methods based on pinch analysis, which are applicable for cryogenic MHEs, are proposed by Saldida [15] and Watson and Barton [12].

The high-performance requirements and demanding operating conditions of cryogenic heat exchangers lead to high manufacturing and installation costs. In air separation and natural gas liquefaction plants, heat exchangers represent 20–30% of the investment costs, as reported by Coyle et al. [16]. Furthermore, the design constraints lead to a very limited variety of the HE construction types and geometries. The main types of heat exchangers used for large-scale cryogenic applications are summarized in Fig. 5.

Fig. 5. Types of heat exchanger used in cryogenic systems.

Fig. 5. Types of heat exchanger used in cryogenic systems.This contribution reviews the recent developments in cryogenic heat exchangers theory and design approaches for large-scale applications. Section 2deals with the tubular spiral-wound heat exchangers which have been widely used since the very beginning of the cryogenic industry. The main features and the latest achievement in plate HE design and manufacturing are presented in Section 3. Special attention is given to the plate-fin HE as the most promising type of cryogenic HE. Printed circuit HEs are also discussed as a highly compact though less common plate-type alternative with a significant potential. The design and future application of regenerators are discussed in Section 4. The conclusions are summarized in Section 5.

2. Coil-wound heat exchangers

The coil-wound heat exchanger (also known as Giauque–Hampson or spiral wound exchanger) has been used since the beginning of industrial-scale liquefaction of air, as described by Timmerhaus and Flynn [17]. The design of these heat exchangers involves winding many small-diameter tubes in a helical geometry around a central core tube, i.e., mandrel, as shown in Fig. 6. The tubes are arranged in multiple layers and enclosed in a cylindrical shell. The arrangement is flexible and in more complex configurations allows for multiple streams to be accommodated in a single heat exchanger. Regarding general flow distribution, the high-pressure stream flows inside the tubes, while the low-pressure stream flows across the tube layers on the shell side. The materials used for cryogenic applications are usually aluminum alloys, as specified by Thulukkanam [18].

Fig. 6. The construction of typical CWHE (courtesy of Linde).

Fig. 6. The construction of typical CWHE (courtesy of Linde).A CWHE typically has a heat exchanger area per unit volume in the range of 20–300 m2/m3 [19], which lies between those of shell-and-tube and plate heat exchangers. Therefore, a single CWHE can accommodate a heat transfer surfaceof up to 40,000 m2. Some designs feature a counter-flow arrangement with a very limited number of bypasses, which allows for very close temperature approaches – down to 1.5 K. The special mechanical design mentioned above, with the tube bundle acting as a spring, allows for quick start-up and efficient transient operation. Another advantage is the robust behavior of the heat exchanger during upset or plant trip conditions.

However, the CWHE is associated with high material costs [20] and because the small passages on both sides do not permit mechanical cleaning – it is only suitable for pure solid-free fluids. Another drawback is that this type of equipment is proprietary and the main design and production capabilities were until recently concentrated in only two original equipment manufacturers, as reported by Shukri [21]. Nevertheless, the growing needs of the LNG industry by the end of the Twentieth Century facilitated the development of cryogenic technology outside of the traditional innovation and manufacturing centers in Europe and the USA.

In Norway, a development programme was started in 1985 to collect experimental data and develop simulation models for coil-wound heat exchangers, as reported by Fredheim et al. [22]. The programme involved the construction of two different test facilities – one for measurement of heat transfer rates and pressure drops in the condensing mixtures on the tube side and another one for similar measurements in the evaporating refrigerant on the shell side. The extensive test programme, lasting more than a decade, provided measurements for single-phase and two-phase flows, using different pure and mixed hydrocarbons. The experimental data was used to develop heat transfer and pressure drop correlations, which were implemented in a software tool called COIL. This tool can be used for rating calculations.

To perform both design and rating calculations, as well as static and dynamic process simulations of the main cryogenic heat exchanger in LNG plants, Neeraas et al. have developed more refined heat-transfer and pressure drop models for spiral-wound heat exchangers [23], [24]. The above test facility in Norway was used to obtain experimental data with further measurements for single-phase vapor flow, liquid film flow, and two-phase shear flow. Based on the measurements, using gaseous nitrogen and various hydrocarbons as test fluids, methods for estimation of the heat transfer coefficients and frictional pressure drops were tested and further improved.

Austegard et al. have experimentally investigated the falling film behavior around a tube array simulating typical spiral wound heat exchanger configurations using n-pentane as test fluid [25]. The measurements were compared with empirical models from other sources. The results indicated that those empirical models are not universal and not appropriate when applied to liquids with significantly different properties and closely spaced tubes.

Gupta et al. have published a series of papers on coil finned-tube heat exchangers. They investigated the design and optimization of coil finned-tube heat exchangers by varying the clearance between the shells and the fins [26]. They elaborated an experimental test rig, reproducing modified reverse Brayton cycle using helium as working fluid. The aim has been to acquire experimental data on the effectiveness of the heat exchanger in a real refrigeration cycle [27]. A sectional view of the Gupta’s cross-counter-flow coiled finned-tube heat exchanger is shown in Fig. 7.

Fig. 7. A sectional view of the Gupta cross-counter-flow coiled finned-tube heat exchanger.

Fig. 7. A sectional view of the Gupta cross-counter-flow coiled finned-tube heat exchanger.