Introduction

Main role of ships as transporter of trading commodity has been attached on them since the beginning of recorded human history. Our ancestors used this transportation mode to interact and conduct trading with others who lived in different islands. Development of transportation technology makes the existing ship improved to be suitable to carry various cargos, including high risk compound, such crude oil, from offshore platform or onshore industry to numbers of destination. During this process, ship possibly experiences various loads, and several of them are classified as accidental load. Generally, the loads occur in three main forms, i.e. collision, grounding and explosion [1], [2], [3]. Emergency situation is expected after the loads globally affect ship structure, or even create local damage, and cause oil spill on maritime environment. Very similar situation is experienced by an oil carrier, the Exxon Valdez which operated in Alaska territory. On March 1989, the 300-m-carrier was loaded with crude oil with estimation more than 50 million gallons, which to be transported to California [4].

In its sail, the ship hit a rock and ran aground which evoke remarkable damage on hull structures [5], [6]. Specifically, tearing appeared on the center and starboard cargo tanks, which made oil was spilled to open water of Bligh Reef, Alaska. Furthermore, seawater was found to be infiltrating hull tank, and caused interruption on ship's stability. During this precarious situation, the evacuation is urgently needed, not only for crew, but also spilled oil. Based on evaluation record [7], it is found that poor preparation and inappropriate field execution lead to massive expansion of polluted area. As consequences, mammals and other species surrounding the ship grounding were coated by the spilled oil. The most influenced species is killer whale, which in works of [8] is stated that marine pollution due to the Exxon Valdez incident may lead to extinction of orca subpopulation.

Illustration of the Exxon Valdez's incident indicates that oil spill is serious threat for maritime environment which in same time possibly occurs as the after effect of accidental loading takes place on ship structures. Environmental consequences are one of unavoidable damages due to the spilled oil, which in this case, review on this incident can be good reference for proper estimation and preparation in encountering massive oil spill. Considering this fact, discussion in this work is addressed to present constructive review related to cause and effect marine accident and environmental pollution. Breakdown of major involved factors in oil spill case is discussed in the first part, which is followed by description of statistical data regarding marine accident, and trends of the oil spill case. Evacuation strategy during oil spill is split into several parts, including preparation stage and execution of clean-up method. Discussion regarding after-effect of oil spill on maritime environment is presented in order to widened insight related massive effect of oil compound to ecosystem destruction, which the Exxon Valdez is taken as the prime reference.

Accident statistics on maritime environment

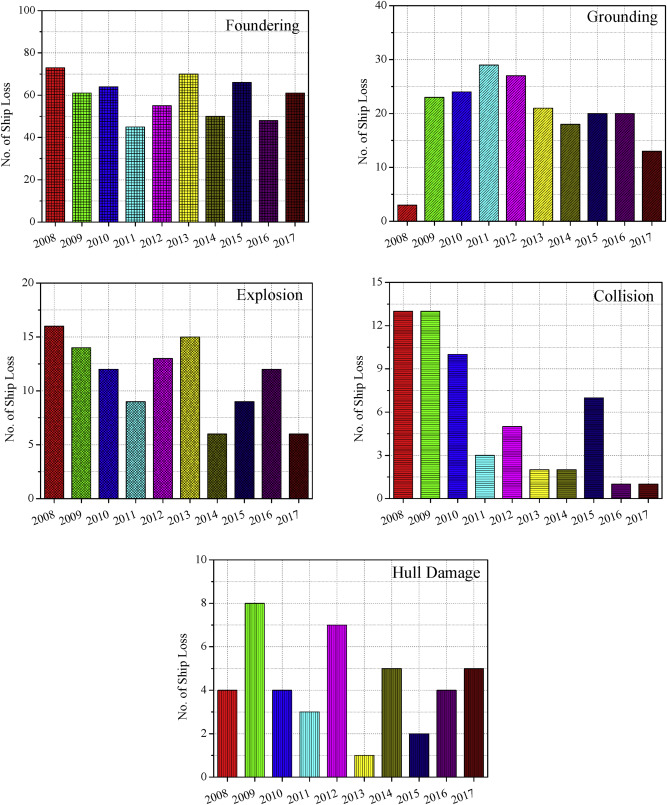

Ship operation in trading is conducted to transport cargo from one location to designated destination, which can be short route or even long route that takes monthly to be reached, such as route from the East Asia to the Middle East through Malacca strait. In the process, challenge of accidental phenomena rise as affected by various factors, such as human error, bad weather, geography etc. Numbers of accidental phenomena are recorded in statistical data presented by Allianz Global Corporate and Specialties (AGCS) in Fig. 1 [9]. The data indicates that losses due to maritime accident in top 5 positions are dominated by accidental loading, e.g. grounding [10], explosion [11] and collision [12]. Other data indicate that foundered as the number one cause of total loss in the latest decade with stable occurrence frequency, i.e. 59.3 times/year. Foundering itself can take place due to the mentioned accidental phenomena, which may require intensive effort to evacuate shipwreck from sea floor.

Fig. 1. Ship loss caused by various accidental events on maritime territory [9].

Fig. 1. Ship loss caused by various accidental events on maritime territory [9].The hull damage is also similar to the foundering as after grounding, explosion or collision occurs, the damage on ship hull is the first expected consequences. It can be in form of tearing, folding or plastic deformation depends on accident scenarios [13]. If these chain processes occur on oil/chemical tanker or nuclear-powered ship, which are dangerous carrier vessels, then remarkable casualties on maritime environment can be immense, either in forms of short or long term damages. Numbers of study are conducted in order to quantify effect of those accidental phenomena to the structural responses and crashworthiness criteria, which as affected of high demand of better safety estimation, the conducted studies are extended to other merchant ships, such as passenger ship [14], container ship and bulk carrier [15].

Correlation between the accidental phenomena with marine pollution, specifically oil spill is true, and this statement is supported by data record of European Environment Agency. In range of the end of 60's until early of 2000, at least top 10 oil spill cases caused by grounding, collision, hull damage and explosion, which the spilled quantities approximately 20000 tones and more (see Table 1). Conclusion of the data indicates that 70% of oil spill happened after ship grounding took place. This accident type also caused the most terrible oil spill case in European sea, when the Amoco Cadiz spilled more than 200000 tons of oil to France water territory. Several remarkable cases of the oil spill in maritime history were recorded with most terrible tragedy was experienced by the Atlantic Empress 1979 with casualties 287000 tones oil spill due to ship-ship collision. In other case, grounding became the cause of 37000 tones oil spill of the well-known Exxon Valdez tanker in Alaska in 1989, or 4000 tones larger than the Nassia's case on Black Sea, Turkey, which resulting collateral damage on maritime environment, including expectation of species extinction.

Table 1. Top ten record of oil spill on European water territory [16].

| Time line | Amount (tonnes) | Spilling vessels | Phenomenon |

|---|---|---|---|

| 1967 | 119000 | Torrey Canyon | Grounded |

| 1975 | 88000 | Jakob Maersk | Grounded |

| 1976 | 100000 | Urquiola | Grounded |

| 1978 | 223000 | Amoco Cadiz | Grounded |

| 1991 | 144000 | Haven | Exploded |

| 1992 | 73500 | Aegean Sea | Grounded |

| 1993 | 84000 | Braer | Grounded |

| 1994 | 33000 | Nassia | Collided |

| 1996 | 72360 | Sea Empress | Grounded |

| 2002 | 62657 | Prestige | Damaged hull |

Global trends on oil spill case

Over past forty eight years, oil spill incidents have been monitored by non-for-profit organization, namely the International Tanker Owners Pollution Federation (IOTPF), which shows statistics of oil spills greater than 7 tonnes from tankers have decreased (see Fig. 2). Downward trend is observed significantly since beginning of the 1900, and followed by the next major reduction in 2000. This phenomenon is largely affected by advance development of the tanker hull which initially used single hull, to be reformed by new concept of double hull. This structure type becomes mandatory in US territory since 2015 which is milestone to phase out all single hull tankers in US waters. Other supports from navigational technology, such radar, satellite and sonar to detect expected collision and grounding scenarios contribute significantly to downward trends of oil spill.

Fig. 2. Tendency of the oil spill incident greater than 7 tonnes in range 1970–2017 [17].

Fig. 2. Tendency of the oil spill incident greater than 7 tonnes in range 1970–2017 [17].According to IOTPF data, further statistical data indicates approximately 5.74 million tonnes of oil were lost of tanker accident in range of 1970–2017 (see Fig. 3). In the latest decades, there is significant reduction in terms of collective calculation per decade which approximately 5000 tones/year of oil spill case. Nevertheless, despite of this positive trend, the oil spill phenomenon cannot fully vanish from maritime industries. On the set data of oil spill, the latest decade also recorded significant oil spill 10000 tones, and the latest case in the Indian Ocean was included in large spill case which more than 700 tonnes polluted maritime territory. These cases are undeniably affecting structure of water ecosystems surrounding spilled area. When oil silk reaches beach, it will contaminate every part of coastal ecosystem, including rock, sand and water. Furthermore, in the worst case, if the oil contaminate coastal area, then mangrove forest and other wetlands will absorb oil, and they become unsuitable as wildlife habitat. Besides its environmental condition, fauna will be directly impacted as they are coated by the spilled oil. This phenomenon is not only experienced by water mammals and fish, but also bird species. Contamination on these parties are causing great reduction in number of species as they loss breeding grounds. Recovery of these parties will be years, and in several remarkable cases, certain mammals, bird, fish and plant population is too late to be saved, and they are stated as extinct species.

Fig. 3. Quantity of annual oil spill recorded by IOTPF [17].

Fig. 3. Quantity of annual oil spill recorded by IOTPF [17].Study case: the Exxon Valdez's evacuation

Technical strategy and challenge

After the Exxon Valdez incident took place, oil containing and evacuation planning were conducted. The Office of Special Counsel (OSC) organized several responses to oil spill case, including anticipation during evacuation. In structuring the response, main goal is set to be preventing the additional spilled oil from damaged hull of the Exxon Valdez. Water condition is assumed to make the hull unstable, thus it is the primary concern together with possibility of ship capsize. This situation can make approximately remaining 43 million gallon of crude oil in ship hull may be spilled to open water. When large ship such as cargo carrier and tanker capsize, other chain reaction is possible, i.e. ship sinking. Great environmental damage in this case can be expected not only from the oil, but also shipwreck. At that time, the technology of surfacing system for ship recovery was yet to be installed [18].

Condition of the massive pollution makes environmental protection is top priority, which the National Oceanic and Atmospheric Administration (NOAA) was involved in expected damage identification. Critical area was concluded on fish hatcheries, and protection equipment, i.e. booms and skimmers (in Fig. 4) to be deployed. Boom is a floating balloon-like equipment which becomes first-line defense in containing oil spill on open water. The boom is set on surrounding area of the spilled oil which makes restricted area and reduce possibility of expansion attempt of oil silk to wider area. On the other hand, skimmer is a device to take the spilled oil on water to more local space, such as drum or tank. The working system of the skimmer is a drum which is submerged every-so-slightly beneath the surface on the spilled area, and the oil on the surface gets rushed to fill the drum. In case of the Exxon Valdez, the Special Counsel had to make priority regarding protection area (i.e. fish hatcheries) due to limitation of available booms and skimmers on field. Besides consideration to the oil containment strategy, safety of evacuation team was another critical concern. Fume of the spilled oil can be toxic, and affected health condition through respiration system. As counter measure, task force for safety and health was deployed. All technical evacuation members were given safety plan (instruction and training) for execution plan on the Exxon Valdez.

Fig. 4. Technical equipment in containing spilled oil: a) boom, and b) skimmer [19], [20].

Fig. 4. Technical equipment in containing spilled oil: a) boom, and b) skimmer [19], [20].After preparations and considerations were completed, the main strategy was executed to fully evacuate approximately more than 10 million gallons of the spilled oil on the Alaska's water environment. Several parties were designated with specific job-desk on the field, i.e. [18]:

-

1.

National Strike Force (NSF) was mobilized to assist control of additional oil release from the Exxon Valdez's hull.

-

2.

Exxon Company activated emergency center in Houston in order to act as control center for field management of technical equipment addressed to stabilize the vessel.

-

3.

Exxon Baton Rouge was deployed directly to the scene in order to offload the remaining oil cargo inside the Exxon Valdez.

During the execution, challenge began to arise, which equipment shortages delayed the evacuation opportunity to contain the spilled oil. A barge that supposed to provide containment facility at the scene had to be repaired, specifically in terms of the barge equipment. Another problem was time consuming to reload barge, and loading of the equipment to the barge was delayed due to the crane was used to load transfer equipment on a tug. Finally, the barge left for the vessel 10 hours after the spill and arrived on scene 2 hours later.

Based on this description, there are three stages in containment plan in case of oil spill, i.e.: preliminary strategy plan, including damage identification, critical area priority, equipment estimation, and execution plan. The next stage is the execution plan on the field, i.e. establishing communication and logistic center, stabilizing ship stability, pumping the remaining oil on cargo tank, and mobilizing skimmer and boom. The third stage is treatment of the evacuated oil from the accident spot. Readiness of barge to transport the oil will take main role in order to keep sustainability of evacuation progress [18].

The major challenge of the oil evacuation is shortage and lack of readiness of the technical equipment on the field. Even though strategy and procedure in containing oil spill have been well prepared, numbers of boom and skimmer are important aspects which should be ready. Other problems worth to be noted is execution management related to additional facility for direct oil containing, such as barge is important factor, especially if large size of oil spill takes place. Oil company has a main role, besides government to complete the containment execution. The company needs to develop specific emergency plan as countermeasure during its fleet is stranded, and causes oil spill. Standardization of mitigation and evacuation of oil spill has to be established based on disaster level so that hindrance in field can be pressed to the lowest degree.

Clean-up methods of oil spill

Dispersant

The first option to consider for cleaning oil spill is dispersant use (Fig. 5). This method became a controversial issue in response strategy during evacuation of the Exxon Valdez. The OSC which has responsibility to press casualty level of water environment concerned that dispersant will have negative impact to water species. However, from international perspective, dispersants use has gained wide acceptance recently as one of several alternatives for oil spill response. Comprehensive overviews on the authorization, preparedness and use of dispersants are provided by the ITOPF and the International Petroleum Industry Environmental Conservation Association (IPIECA) [21], [22], [23]. Application of this compound as countermeasure of oil spill is affected by several factors, such as sea state and spilled oil type. Dispersant use is easier to be applied in moderate sea state and the spilled oil is light or medium type. On contrary, dispersant use will face challenge if the sea state is flat (very calm water territory) and high sea (storm, bad weather etc.). Heavy oil is also influence efficiency of the dispersant use, which makes the oil will be harder to be dispersed. The working phase of dispersant use itself is divided into five:

-

•

Dispersant is mobilized from airplane to the contained spill area

-

•

Dispersant reacts to oil silk, and reaction of these compounds becomes droplet forms

-

•

Bacteria on the water territory colonize the dispersed oil droplets

-

•

Bacteria break down the dispersed oil droplets

-

•

Other organism assist the process