Introduction

Lignocellulosic agricultural and forestry wastes, sewage/solid wastes, high-volume by-products such as glycerol are biowastes which are potential chemical feedstocks [1]. Although biomass and biowastes present great opportunities in the chemicals and fuels space, their widespread adoption has been a challenge, partly due to the lack of efficient catalytic routes to produce high value derivatives in high yield [2]. Since catalytic reaction engineering lies at the heart of process/technology development, rational design and development of heterogeneous catalysts is believed to be a key factor for a sustainable future [3].

The explanatory capabilities of first principles computational investigations have deepened our understanding of a wide range of aspects relevant to surface catalytic phenomena and have aided in improving capabilities of rational catalysts design [4]. Recent advances in computational methods and high-performance computing are bringing the predictive potential of such computations to the forefront, making ‘in silico’ or computational design of heterogeneous catalysts an imminent reality [5]. With examples primarily on upgrading of biowastes such as glycerol, lignin and its derivatives, this article discusses developments in the last three years in computational catalysis which can pave the way towards computational design of catalysts.

The article is organized as follows. The key challenges for design of catalysts for upgrading of biowaste, and challenges in the computational investigations of such phenomena are briefly presented in Section ‘Challenges in catalysis for biowaste upgrading and in computational investigations of catalytic phenomena’. Representative computational catalysis investigations that derived mechanistic insights crucial for catalyst design are discussed in Section ‘Deriving mechanistic insights’. Computational efforts and tools in identifying structure of catalyst nanoparticles are discussed in Section ‘Identification of structure of catalyst nanoparticles structural evolution at reaction conditions’. In Section ‘Computational screening of catalysts: catalytic descriptors and scaling relationships’, computational tools that enable screening of potential catalysts and prediction of catalytic performance are discussed with examples. Recent trends in application of machine learning and data repositories in computational catalysis are presented in Section ‘Computational catalysis with machine learning and materials/catalysis databases’. A summary of recent trends and perspective on future directions is presented in Section ‘Conclusions and perspective’.

Challenges in catalysis for biowaste upgrading and in computational investigations of catalytic phenomena

Biomass and biowastes molecules are characterized by high abundance of oxygen containing functional groups. Many of the catalytic processes for upgrading of biowaste derivatives require selective elimination and/or transformation of these functional groups, which are challenges [6]. Bifunctional catalysts containing at least two active sites which may cooperate to facilitate the same elementary reaction step or facilitate two separate elementary steps have been identified as the most promising candidates for these reactions [7]. Bimetallic catalysts and metal-metal oxide couple catalysts are prominent examples in this category. However, 1) making appropriate choice of the combination of materials with their optimum composition, 2) ability to design for desired surface functionality, and 3) ability to tune surface functionality for desired reactivity and product selectivity continue to be challenges.

The number of computational investigations of catalytic upgrading of biowaste has been increasing rapidly and some of the emerging trends are summarized in recent review articles [8, 9, 10]. Although such investigations have contributed significantly to our understanding of catalytic phenomena, advances towards computational design of catalysts have been slow. This is due to challenges in computational investigations of such systems, specifically: 1) molecules are fairly complex, making it necessary to evaluate large numbers of surface intermediates and elementary reaction steps, 2) reactions are typically carried out in aqueous medium, necessitating investigation of solvent effects on catalyst structure and properties, and on surface kinetics and thermodynamics, 3) observables are significantly influenced by reaction conditions, making it necessary to calculate free energies which is computationally intensive for condensed phase systems [9,11].

Computational directions, methods and obtained insights for design of catalysts

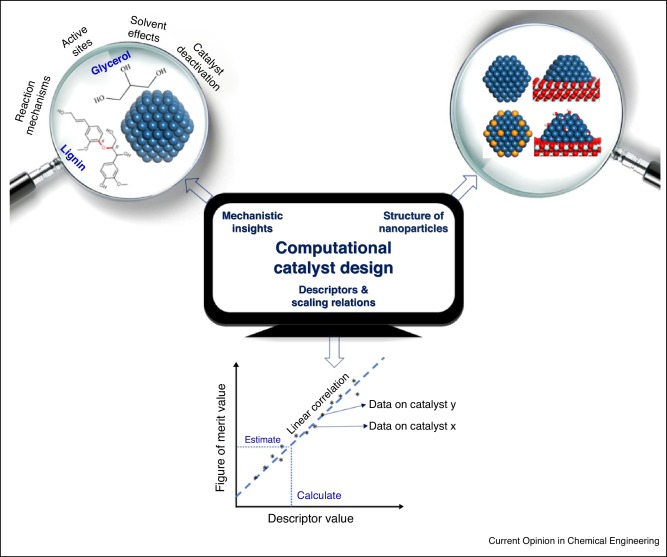

Computational heterogeneous catalysis traditionally relied on mechanistic insights derived using Density Functional Theory (DFT) calculations on ideal catalyst surfaces and computational screening/design of catalysts relied on descriptor-based scaling relations and kinetic modelling [4]. Keeping pace with ‘operando’ investigations in catalysis [12], the computational model catalyst systems are becoming realistic, and by applying multiscale computational methods, we are making rapid strides towards ‘operando computational catalysis’ [13,14]. Computational design of catalysts requires mechanistic insights on the reaction chemistry, structure and evolution of the catalysts under reaction conditions and methods for the rapid screening of potential catalysts. All these aspects are discussed in this section with suitable examples (Figure 1).

Figure 1. Aspects that will contribute towards computational design of catalysts.

Figure 1. Aspects that will contribute towards computational design of catalysts.Deriving mechanistic insights

Identification of active sites and reaction mechanisms on catalysts

For information regarding fundamentals of the techniques and methods described in this section, readers are directed to the review article covering these topics [15]. All the aspects covered in this section are summarized in Figure 2.

Figure 2. Schematic representation of computational techniques to derive mechanistic insights on heterogeneously catalyzed surface phenomena.

Figure 2. Schematic representation of computational techniques to derive mechanistic insights on heterogeneously catalyzed surface phenomena.Potential energy surface (PES)

DFT calculations of elementary reaction steps on representative model catalyst systems enable the construction of PES for the reaction network. Analysis of the PES with the corresponding system geometries provides insights into the active sites on the catalyst and reaction mechanisms.

Analysis of the DFT derived PESs for the hydrodeoxygenation of glycerol on Ir and ReOx-Ir coupled catalyst gave insights on the bifunctional catalysis by Ir and the Brønsted acidic Re-OH sites, enabling selectivity to 1,3-propanediol (1,3-PDO) [16•]. The analysis in conjunction with experimental observations also qualitatively explained the volcano type behaviour on the Ir:Re composition (optimum composition Ir:Re = 1) of the catalyst for optimum yield of 1,3-PDO. At high and low Ir:Re ratio, the catalyst exhibited activity and product selectivity similar to metallic Ir and ReOx catalysts, respectively; however, both are inactive and produce 1,2-propanediol.

Understanding the factors determining the depolymerization of lignin by hydrogenolysis is crucial for developing processes for its valorization [17]. Analysis of DFT PESs showed that Ru-doped Ni catalyst is more effective for the hydrogenolysis of lignin as it exhibited a lower activation barrier for the β-O-4 link cleavage (C O bond cleavage) in a lignin surrogate than Ni catalyst [18•]. The oxophilic nature Ru metal was found to be responsible for the lowering of activation barrier. This implied that doping small amounts of oxophilic metals with Ni would enhance its activity while high loading of such metals may lead to its deactivation due to strongly bound oxygenate intermediates. A similar positive effect of alloying oxophilic metals such as Re [19] and Fe [20,21] with Ni in enhancing efficiency of C

O bond cleavage) in a lignin surrogate than Ni catalyst [18•]. The oxophilic nature Ru metal was found to be responsible for the lowering of activation barrier. This implied that doping small amounts of oxophilic metals with Ni would enhance its activity while high loading of such metals may lead to its deactivation due to strongly bound oxygenate intermediates. A similar positive effect of alloying oxophilic metals such as Re [19] and Fe [20,21] with Ni in enhancing efficiency of C O bond cleavage in lignin derived aromatics has been reported.

O bond cleavage in lignin derived aromatics has been reported.

Free energy surface (FES)

When temperature and entropic effects have significant contributions to surface phenomena, the FES is required to provide experimentally relevant insights and predictions. This is especially the case where adsorption and surface coverage determine the surface catalytic phenomena.

In accordance with the analysis of DFT calculated FESs for the hydrodeoxygenation of furfural (biomass pyrolysis derivative) on Ni and boron-doped Ni catalysts (Ni-B) at the relevant surface coverage of hydrogen, it was shown that boron doping has a significant promotional effect on catalytic performance [22•]. Boron doping lowered the activation barrier for the rate determining step and enhanced the adsorption strength of surface intermediates, without altering reaction pathways. This investigation predicted Ni-B as a potential alternative to the expensive Ru catalyst typically used for this reaction.

Microkinetic modelling (MKM)

Quantification of the effect of sensitivity of elementary reaction steps to microscopic surface structures and their effects on macroscopic and measurable parameters such as rate constants and catalytic turnovers is best accomplished using first principles microkinetic modelling. Identification of rate determining steps and analysis of surface coverage of key species give indications on how catalysts can be altered to enable enhanced catalytic turnovers or desired product selectivity.

DFT-based MKM evaluation of the dehydration of glycerol to propylene on MoO3 catalyst revealed the key role played by the surface lattice oxygen vacancy sites in the C O bond cleavage steps, which are the key steps in the process [23]. Pre-reduction of the catalyst with H2 or high H2 pressure during reaction generated these vacancies by elimination of water in the Mars van Krevelen mechanism. The inefficiency of MoO3 for H2 dissociation, evident from the highest activation barrier among all the elementary steps, is a limitation in the performance of this catalyst.

O bond cleavage steps, which are the key steps in the process [23]. Pre-reduction of the catalyst with H2 or high H2 pressure during reaction generated these vacancies by elimination of water in the Mars van Krevelen mechanism. The inefficiency of MoO3 for H2 dissociation, evident from the highest activation barrier among all the elementary steps, is a limitation in the performance of this catalyst.

MKM can be computationally very expensive for investigation of larger complex molecules where many elementary steps must be investigated. An alternative to investigating all elementary steps is to use adsorption and transition state scaling relations. Such a strategy of using scaling relations together with explicit calculations of elementary steps was demonstrated in the DFT MKM investigation of aqueous phase reforming of glycerol on Pt catalyst [24••].

Reactive molecular dynamics simulations

Reactive molecular dynamics simulation is an excellent tool to investigate surface phenomena in liquid phase as this technique inherently samples the complexities in the configurational space and can be used to reconstruct the free energy landscape for the reactions.

ReaxFF [25]-based MD simulations of lignin fragmentation on Pd catalyst in methanol-water solvent mixture revealed the dynamics of adsorption of lignin from the solution, the surface reaction initiated by the dissociative attachment via the hydroxyl and desorption of the fragments [26•]. The C O bond cleavage on the Pd(100) surface was marginally faster than on the Pd(111) surface. The MD trajectories also showed that 82–95% of catalyst surface was covered by the solvent molecules, reiterating the need to investigate competitive interaction of the solvent and substrates on the catalyst.

O bond cleavage on the Pd(100) surface was marginally faster than on the Pd(111) surface. The MD trajectories also showed that 82–95% of catalyst surface was covered by the solvent molecules, reiterating the need to investigate competitive interaction of the solvent and substrates on the catalyst.

Solvation effects on catalytic activity and product selectivity

The presence of solvent can have wide ranging effects on the activity of the catalysts and product selectivity. For detailed inputs on solvent effects in catalysis and computational techniques to study such effects, readers are directed to a recent review article [11].

Understanding the effect of solvents in influencing the adsorption of lignin surrogates on different catalysts is important for making choices of catalysts for its depolymerization. Combined classical MD and DFT analysis of the adsorption energies of lignin dimer in ethanol solvent on Cu and Ni catalysts suggested that the lignin would adsorb on the Ni catalyst and not on the Cu, making Ni a preferred catalyst for hydrogenolysis [27].

DFT-based MKM using the implicit solvation scheme for metal surfaces (iSMS) [28], investigating the hydrodeoxygenation of methyl propionate on Pd(111) surface in water and 1,4-dioxane solvents showed that the dominant decarboxylation pathway in water had an activity that was an order of magnitude lower than the dominant decarbonylation pathway in 1,4-dioxane [29]. This shows the potential to change catalyst activity and product selectivity by changing the solvent. The lower reactivity in water was due to increased stability of a surface intermediate which saturated the catalyst surface.

MKM-based investigation of aqueous reforming of glycerol on Pt catalyst showed multiple roles of water in the reaction network which included 1) dissociative adsorption to form hydroxyls which promoted CO oxidation, 2) kinetic and thermodynamic inhibition of C H bond activation steps, 3) kinetic and thermodynamic promotion of O

H bond activation steps, 3) kinetic and thermodynamic promotion of O H bond activation steps, and 4) thermodynamic inhibition of decarbonylation step [24••]. The MKM derived product selectivity matched experimental observations only when water was explicitly incorporated in the reaction scheme.

H bond activation steps, and 4) thermodynamic inhibition of decarbonylation step [24••]. The MKM derived product selectivity matched experimental observations only when water was explicitly incorporated in the reaction scheme.

Chemical deactivation mechanisms of catalysts and means to resist them

Impurities in feed streams can deactivate catalysts, while in some other cases, reversible structural changes in the catalysts may result in loss in activity, necessitating its regeneration. The latter is often the case of reducible metal oxide catalysts undergoing reduction. Understanding catalyst deactivation is crucial to design catalysts to resist it.

Amino acids impurities in biomass fermentation derived feedstock are responsible for deactivation of Ni and Pd catalyst used for liquid phase hydro processing of the derivatives [30]. A combination of MD simulations and DFT calculations revealed the strong interaction of S atoms in amino acids with Ni catalyst in the aqueous phase, explaining the irreversible deactivation of the catalyst [31•]. Although bimetallic Ni-Au catalyst is likely to overcome this limitation due to its weaker interaction with the amino acids, making it a promising candidate with resistance to deactivation [31•], Pd-Au catalyst had nearly similar interaction with the amino acids as Pd catalyst, making both of them susceptible to deactivation [32].

CuO catalyst gave high yield in the oxidation of glycerol to dicarboxylic acids such as tartronic acid and oxalic acid with H2O2 promoter [33••]. Reaction without H2O2 led to rapid deactivation of the CuO catalyst due to its reduction to metallic Cu. DFT calculations showed that the hydroxyls resulting from the dissociation of H2O2 not only opened an alternate reaction pathway for glycerol oxidation, without consuming the lattice oxygen by the Mars van Krevelen mechanism, but also refilled lattice oxygen vacancies. Both these prevented the reduction of CuO and thereby prevented deactivation.

Identification of structure of catalyst nanoparticles structural evolution at reaction conditions

Identification of stable structures of catalyst nanoparticles at the operating conditions, understanding the metal-support interactions and their influence on the electronic and geometric properties of the catalyst, understanding/predicting structural evolution of nanoparticles under the influence of surface species are all crucial in making realistic catalyst models to enable accurate computational predictions. Representative recent investigations in these directions, although not originally performed for biowaste feedstocks, are presented in this section, as the methodologies adopted, and insights drawn are applicable for such systems as well. For more details on computational techniques used and other examples, readers are directed to review articles covering this topic [13,14,34]. Schematic illustrations of isolated catalyst nanoparticles and supported nanoparticles are given in Figure 3.