1. Introduction

Gas condensate reservoirs may happen at pressures less than 2000 psia and temperature below 100 °F and probably can occur at any higher temperatures and pressures within reach of the drill string (Ikoku, 1984). The trend to drill deeper in many areas has led to the discovery of reservoirs with higher pressures and temperatures. It tends to result in the discovery of a greater proportion of condensate and dry-gas reservoirs, as is evident from phase diagrams. Gas condensate reservoirs also contain a large volume of gas reserves as well as appreciable amounts of light density, high API quality condensate. The increasing everyday consumption of energy makes it very important to maximize the exploration and production from such reserves.

The problem associated with condensate accumulation has been documented in the literature. The Arun field in Indonesia, one of the world's largest retrograde gas condensate reservoir, for example, showed that the well productivity was reduced by 50% when the maximum liquid drop out in the reservoir was around 1% (Afidick et al., 1994). In another case in Cal Canal field, California, a poor primary recovery was reported as a result of reduction in gas relative permeability due to accumulation of condensate and severe liquid loading (Engineer, 1985). Others largest gas-condensate reservoirs that also experiencing the same condensate blockage effect are Cupiagua field in Colombia, Karachaganak field in Kazakhstan, North field in Qatar which borders with the South Pars field in Iran, and the Shtokmanovskoye field in the Russian Barents Sea (Miller et al., 2010).

The low mobility of gas and condensate due to heavy liquid-wetting of rocks around wellbore is the major reason of liquid accumulation and blockage occurrence. Hence, it is regarded to be the key strategy to enhance gas recovery in a gas condensate reservoir by altering the wettability of the rock from liquid-wetting to less liquid-wetting or gas-wet. Gas-wettability is defined as the ability of gas to cover solid surfaces with greater preference than liquids that are immiscible with gas in a gas-liquid-solid system (Jiang, 2018). Through wettability alteration, the liquid phase mobility in a gas-liquid system is significantly increased and hence, improving the gas well deliverability in a gas condensate reservoir.

2. Condensate banking

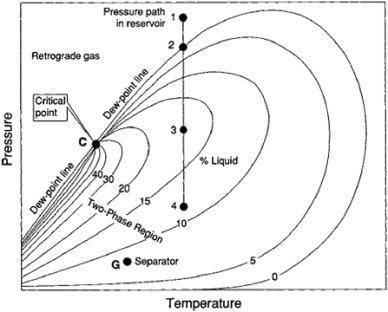

The phase behaviour of gas condensate reservoirs revealed that with production and the continuous decline of the reservoir pressure, the heavy components in the gas stream would start to condense and form liquid condensate (Sayed and Al-Muntasheri, 2016). Fig. 1 is a pressure-temperature diagram for a typical gas condensate fluid system. This liquid condensate will form and accumulate in the area very close to the wellbore where the pressure drop is maximum, and the flowing pressure will be minimum compared to the reservoir pressure (Gringarten et al., 2000; Sayed and Al-Muntasheri, 2016).

Fig. 1. A typical phase diagram of a retrograde gas-condensate system (McCain, 1989).

Fig. 1. A typical phase diagram of a retrograde gas-condensate system (McCain, 1989).As more production takes place, more liquid hydrocarbon condense and accumulate in the pore as a direct result of the strong liquid wetting affinity to the rock surface. This accumulation of liquids and formation of liquid banking will result in an increase in the liquid saturation which may reach 40–70% in the area very close to the wellbore (Marokane et al., 2002; Whitson et al., 1999). This will contribute towards a drop in the gas effective permeability, and thus a drop in the well's production of gas and causes an impact on the condensate processing facility (Ahmed et al., 1998; Barnum et al., 1995; McCain and Alexander, 1992).

Four different mobility regions in the reservoir are created as the fluid changes from a single-phase to two-phase in near wellbore region, as shown in Fig. 2, Fig. 3. In Region 4, away from the well, only gas is present as the reservoir pressure is still above the dew-point pressure. A small drop of condensate is observed at the dew-point pressure boundary as shown in the boundary of Region 2 and 3. Region 1 and 2 are closer to the well and the pressure is below the dew-point, hence the condensate forms out of the gas phase. In Region 2, the condensate is not mobile as the condensate saturation is below a critical value. In Region 1, both condensate and gas are mobile and flow together into the wellbore, as the condensate saturation is above a critical value. Region 1 and 2 are designated as the condensate bank regions, and the reduction in gas effective permeability corresponding from condensate banking occurrence can have a powerful effect on the well's productivity (Al-Yami et al., 2013; Bang, 2007).

Fig. 2. Aerial view of regions around the wellbore of a well drilled in a gas condensate reservoir (modified from Bang (2007)).

Fig. 2. Aerial view of regions around the wellbore of a well drilled in a gas condensate reservoir (modified from Bang (2007)). Fig. 3. Side view of regions around wellbore of a well drilled in a gas condensate reservoir (modified from Al-Yami et al. (2013)).

Fig. 3. Side view of regions around wellbore of a well drilled in a gas condensate reservoir (modified from Al-Yami et al. (2013)).In addition, Fig. 4 shows the schematic diagram of a vertical wellbore and the condensate banking occurrence. When the drawdown pressure hit below the dew point pressure, a small drop of condensate is formed and accumulated in the near wellbore region. As the accumulation occurs, the liquid saturation will also increase and the gas relative permeability is reduced, hence affecting the productivity.

Fig. 4. Schematic diagram of condensate banking problem (modified from Al-Yami et al. (2013) and Sharifzadeh et al. (2013)).

Fig. 4. Schematic diagram of condensate banking problem (modified from Al-Yami et al. (2013) and Sharifzadeh et al. (2013)).3. Condensate banking mitigation methods

The problem of condensate in gas wells have been previously discussed and several techniques have been proposed to resolve this issue. Table 1 shows a summary of the techniques used to mitigate the condensate banking problem. These techniques include:

-

•

Gas injection – where natural gas, nitrogen or carbon dioxide can be pumped into the reservoir aiming to increase the reservoir pressure to be above the dew point pressure (Al-Abri and Amin, 2009; Aziz, 1983; Donohoe and Buchanan, 1981; Havlena et al., 1967; Jessen and Orr, 2003). This technique is ideal, but the problem is that the cost of the treatment can be high and there is a market for natural gas.

-

•

Horizontal wells – it will increase the contact area between the reservoir and the wellbore, hence, it will improve the wells productivity index and delay the phenomenon of condensate banking in the area around the wellbore (Al-Anazi et al., 2006; Barnum et al., 1995; Dehane et al., 2000; Hinchman and Barree, 1985; Miller et al., 2010).

-

•

Hydraulic fracturing – whether acid fracturing, fracturing using conventional fluid systems and matrix acidizing, its aim is to improve the productivity of the well through creating conductive paths to increase the contact between the reservoir and the wellbore (Butula et al., 2005; Franco et al., 2011; Ignatyev et al., 2011; Khan et al., 2010).

-

•

Interfacial tension reduction – use of solvents such as alcohol (methanol or isopropanol) will reduce the interfacial tension between liquids and gases, and in return will improve the gas relative permeability and increase the productivity of both gas and condensate (Ahmed et al., 1998; Al-Anazi et al., 2002; Alzate et al., 2006; Sarkar et al., 1991). This solution, however, is a temporary measure as alcohol removes the liquid by a multiple contact miscibility displacement.

-

•

Wettability alteration – the main concept in wettability alteration treatments is to inject a chemical and modify the rock surface wettability from liquid-wet to neutral-wet or even preferentially gas-wet (Bang et al., 2010; Sharifzadeh et al., 2013; Tang and Firoozabadi, 2002). This will improve the liquid phase mobility by a factor of 3.5–3.85 as indicated in Hoseinpour et al. (2019) and hence help gas to push the liquids (both water and condensate) from the pore space out to the wellbore. However, this technique is still at the research stage, only reducing surface free energy without surface roughness and affects gas relative permeability (Bang, 2007; Bang et al., 2008a; Kumar et al., 2006; Li and Firoozabadi, 2000a; Noh and Firoozabadi, 2008).