1. Introduction

With the rapid increase in the Indian Automobile market, Electric Vehicles (EVs) are turning into a promising channel towards improving air quality, energy security and economic opportunity. The government of India recognizes the urgency to look at sustainable mobility solutions to reduce dependency on imported energy sources, reduced greenhouse gas emissions and mitigate adverse impacts of transportation including global warming. The carbon dioxide emission can be reduced by taking precautionary measures to reduce the catastrophic climate change that threatens the species of this planet. Major endeavours have been taken for minimal use of fossil fuels for power generation, transport propulsion, reduction of energy consumption and protection of carbon sequestration. EVs could be the alternative to decrease the carbon dioxide gas emission [1].

Though the use of EVs has begun, people are still depending upon fossil fuel powered vehicles. However, the EVs are facing challenges on life cycle assessment (LCA), charging, and driving range compared to the conventional fossil fueled vehicles. The CO2 emitted from Electric vehicle production is (59%) more than that of the ICEV. The ICEV generates 120 g/km of CO2 emission on a tank to wheel basis, but from the point of view of the LCA, this increases to 170–180 g/km. While EV has zero emissions of CO2 on a tank to wheel basis, we estimate that the average CO2 is measured over the life cycle of a vehicle rather than over a vehicle. The total CO2 emission over its full life time varies significantly depending on the power source where the vehicle is manufactured and driven [2].

Harmful emission from the transport sector, and investment by different OEMs, there arises a concern for growing more and low cost EVs in the forthcoming years. Several factors such as technological advancement, reduction in the cost of a vehicle, Govt policy support, vehicle purchasing incentives, parking benefit, and good public charging infrastructure facility could result in the uptake of EVs in India. As the production of EVs is very low, the overall share of EVs in the Indian market is negligible. EVs can be i) electric two wheelers (E2Ws) like electric bicycles and electric scooters, ii) three wheelers like E- rickshaws and iii) four wheeler consists of electric cars. India's first electric car company “The Reva Electric car” which launched its car in the early 2000s focuses to produce affordable cars through advanced technology. The only BEV manufacturer, Mahindra Electric mobility Ltd is leading in the Indian market. Other major HEV manufacturer companies operating in Indian markets are Toyota Kirloskar Motor Pvt. Limited, BMW AG, Volvo Car Corporation and Honda Motors Co. Ltd. Some of the other models were Mahindra e2oPlus, Mahindra e-Verito, Mahindra e-KUV 100, Eddy Current Controls Love Bird, Atom Motors Stellar, and Tata Tiago Electric [3].

In 2014, India's overall greenhouse gas emission amounted to 3202 million metric tonnes of carbon dioxide equivalent, which accounted for 6.55% of global greenhouse gas emissions. In India, 68% of greenhouse gas emission come from the energy sector, followed by agriculture, manufacturing processes, improvements in land use and forestry, and waste adding 19.6%, 6.0%, 3.8% and 1.9% relative to greenhouse gas emission [4].

An electric vehicle can be used as a flexible load for standardizing the grid with a substantial share of fluctuating renewable energy generation [5]. The owners of the Electric vehicle do not have a transaction in the electricity market due to the low power of a single transaction [6]. Some authors [7], [8], [9], [10], [11], [12] considered a current practice for the estimation of current smart policies, which were established in advance for changing scenarios and are exogenous. To exploit the full potential of an EV, flexible load, and smart charging strategies should be executed. In another study by [13] revealed that, the EV users organized themselves to impart to the aggregator as far as timing and energy necessity. The timing requirement defines the time by which a charging operation must be completed, whereas the battery level supports the energy requirement. In a similar study conducted by [14] indicated that a decentralised framework and a central entity should provide the pricing signal to owners of electric vehicles expecting the centralised and decentralised frameworks to overlap.

Brady and Mahony, 2016 [15] studied the stochastic simulation methodology of an electric vehicle for generating a dynamic travel schedule and charging profile for the propulsion of the EVs in this real world. They concluded that when the conditions of parking time distribution are increased, the parking time distribution accuracy, as well as the overall accuracy of the model, would be improved. Morrissey et al., 2016 [16] studied some electric vehicle consumers and revealed that they prefer charging their vehicles at their home during peak electricity demand in the evening. Foley et al., 2013 [17] studied the impact of EV charging under peak and off-peak charging scenarios in a single extensive electricity market in Ireland and found that the peak charging is detrimental compared to off-peak charging. Doucette and Mc Culloch, 2011 [1] conducted a study on the BEV and the PHEV to determine their carbon dioxide emission level and compared their results with CO2 emission from Ford Focus. Steinhilber et al., 2013 [18] studied the essential tools and strategies for introducing new technology and innovation by exploring key barriers to an EV in two countries. Yu et al., 2012 [19] introduced a driving pattern recognition technique for evaluating the driving range of the EVs based on the trip segment partitioning algorithm. Hayes et al., 2011 [20] investigated for different driving conditions and topographies by building up a vehicle model. Salah et al., 2015 [21] studied the EVs charging impact on Swiss distribution substation and found that higher penetration level and dynamic tariff increases the risk of overloads at some locations. These parameters are then compared with each other by their range type. The impact of various classifications of charging methodology of electric vehicles on the national grid and the storage utilization has been presented by [22], [23], [24], [25], [26] studied the model-based non-linear observers for estimating the torque of permanent magnet synchronous motor for hybrid electric vehicles. The maximum transmissible torque method is determined by [27], [28] for increasing the antiskid execution of the torque control framework and to improve the stability of the Electric vehicles. Lu et al., 2013 [29] made a review of key issues for Li-ion battery management in an Electric vehicle. The issue such as voltage of the battery cell, battery state estimation (battery SOC, SOH, DOD and SOF), battery equalization and uniformity and fault analysis of the battery can provide motivation for the research and design of the battery management system. Reviews on optimal management strategies, energy management system and the modelling approach for electric vehicles were studied by [30], [31], [32], [33].

EVs can also interact with the grid via charging and discharging. Different modes of interfacing with the grid, are Grid-to-Vehicle (G2V), Vehicle to Grid (V2G), and Vehicle to Building (V2B).

In G2V, the EV is charged from the grid while in V2G, the vehicle discharges power to the grid. In V2G, there is a capability to control the bi-directional flow of electrical energy between a vehicle and electric grid at regular intervals. The integration of electric vehicles into the power grid is called the vehicle to grid system. Here the energy flows both to and from the vehicle, making it into a portable battery store. In V2B, the energy transfers from the battery to a building.

This paper presents an overview of the barriers and challenges of an Electric vehicle in the Indian context and is the main novelty of this paper.

As the EV market expands, the focus should be on the actual adoption action of EV and not just on the intervention. Furthermore, the gap between intention and actual behaviour is important to consider. Consumer knowledge and skills for estimating and comparing the financial benefit and cost of EV are the major research gap of the current research. Future studies on how to inform customers may have implications for knowing the financial benefit and cost of EV's by policy makers and marketing specialists.

The objective of this study is

To identify the essential methods, barriers, and challenges of using a battery-operated vehicle in a developing country like India.

To identify the reasons why electric vehicle could not get much attention in India.

To create awareness about the added advantages of battery operated vehicles over conventional fossil fueled vehicles in India.

To study different Government initiatives taken in promoting Electric/Hybrid Vehicles.

2. Methodology

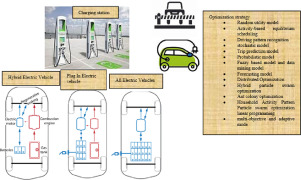

We have studied various types of electric vehicles exiting at present across the world. Besides this, we have figured out the barriers of EV in the Indian market. Different types of optimisation techniques are also discussed and are presented in Table 2. The detailed overview on Electric Vehicles was studied and is presented in Fig. 1. This paper is structured into a few segments such as: Section 2 describes the methodology. Section 3 explains the overview of all types of electric vehicle configuration followed by its charging scenario in Section 4 and the barrier of EV in Section 5. The optimisation technique for EV and V2G is presented in Section 6, followed by a conclusion in Section 7.

Fig. 1

Fig. 13. Electric vehicle overview

The grail behind the electric vehicle is to replace an internal combustion engine with an electric motor which is powered by the energy stored in the batteries through power electronic traction inverter. The Electric motor uses 90–95% of input energy to power the vehicle, which makes it a very efficient one. The key components of an Electric car are battery, charging port, charger, DC/DC converter, power electronics controller, regenerative braking, and drive system.

The purpose of the electric motor is that it utilizes the electrical energy stored in batteries for powering the Electric vehicle. The EVs become environment-friendly as they are recharged with lower emission power sources. The cells are charged from the electric grid. The primary function of the battery is to provide power to the Electric car for making it in running condition. Generally, EVs use lithium-ion batteries because they are more efficient than other cells due to their lightweight and negligible maintenance. The manufacturing of these Li-ion batteries is bit expensive as compared to the nickel-metal hydride and lead-acid batteries. Depending upon the climatic location and maintenance schedule, the Li-ion batteries last up to 8 to 12 years.

The charging port is the point that permits the vehicle to connect with an external power supply system through a charger to charge the battery.

The function of the charger is to take AC supply from the power source using a charge port and converts it into DC power for charging the battery. It also monitors the voltage, current, temperature and state-of-charge of the battery while charging it.

The DC/DC converter converts high voltage DC from the battery to low voltage DC power to run the vehicle accessories. The power electronics controller controls the speed of the traction motor and torque by managing the flow of electrical energy from the traction battery.

The regenerative braking plays an essential role in maintaining vehicle strength and achieving improved energy. This braking method uses the mechanical energy from the motor and converts kinetic energy into electrical energy to give back to the battery. Regenerative braking also enhances the range of the EV, so it is widely adopted in all hybrid and BEV models. Here the electric motor generates forward momentum when the car moves forward, and when the brake is applied, it can be used to charge the batteries, which is known as regenerative braking. It can recover 15% of used energy for acceleration. Being an effective component, it is unable to recharge the electric vehicle fully.

The role of the drive system is to generate motion by transferring the mechanical energy into the traction wheel. Based on the use of the components, the electric vehicle has several internal configurations and does not require conventional transmission. For example, some design uses multiple smaller motors intended for powering each wheel individually. On the other hand, a large electric motor possibly is coupled to the rear wheels using differential housing. The electric-powered vehicle utilizes much simpler components when compared with the elements of a gasoline-powered car engine. However, electric vehicles would not go much faster as a gasoline powered car can.

3.1. Types of electric vehicles

Several countries have developed the EVs, but the broader market of EVs comes from China, UK, USA, and Germany. The EV market is growing remarkably across the world. The vehicles can be arranged into three groups: Hybrid Electric Vehicles (HEV), Plug-in-Hybrid Electric Vehicle (PHEV) and Battery Electric Vehicle (BEV).

3.1.1. Hybrid electric vehicle

A hybrid electric vehicle consist of IC engine and electric motor. Here the batteries get charged by the engine and by the energy generated when decelerating and braking. In the current scenario, they are referred to as hybrid vehicles because they combine a combustion engine and an electric motor as a power converter.

Hybrid electric vehicle technology is deployed worldwide as they have many advantages of offering contemporary performance with no worry about the charging infrastructure dependency. They can also reduce fuel consumption to a great extent through electrification of powertrain. The HEV can be connected in many topologies depending upon the type of hybrid system. These are series hybrid, parallel hybrid, and power-split hybrid.

In a series hybrid, the electric motor is the only means to provide power to the wheel. The motor gets the power either from the battery or from the generator. Here the batteries are being charged through an IC engine to provide power for driving electric motor. The computer decides amount of power originates from battery or the engine/generator. Both the engine/generator and the utilisation of regenerative braking energize the battery pack [34].The series HEV usually have a bigger size battery pack and large motors with a small internal combustion engine. They are assisted by ultra-caps, which help in improving the efficiency of the battery, thereby decreasing the loss. During braking, they take regenerative energy and deliver peak energy during acceleration. Their advantages of using series hybrid drive train are i) Ideal torque-speed characteristics of electric motor make multi-gear transmission un necessary ii) Mechanical decoupling between the internal combustion engine and drive wheels allows the IC engine operate at its narrow optimal region. However, a series hybrid drive train has some disadvantages. They are i) the overall efficiency be reduced because the energy is converted twice, i.e., from mechanical energy to electrical energy and then to mechanical energy ii) Here big traction motor and two electric machines are required because it is the only torque source of a driven wheel. These vehicles are typically used in a military vehicles, commercial vehicles, and buses since they have adequate space for their large engine/ generator system [35].

In a parallel hybrid, the engine is connected directly to the wheels, which leads to smaller energy loss and less flexibility in the mutual positioning of the powertrain components compared with the series HEV drivetrain as well. Here the power is supplied from engine, motor, or from the combustion of both motor and engine to the wheel. Parallel hybrid can drive the vehicle individually or together (the combination of single electric motor and ICE). Generally, it has small battery packs that rely upon regenerative braking to keep it recharged.

In Power-split hybrid system, motor, generator, and the engine, all are attached to a transmission with a planetary gearbox. They can be arranged in both series and parallel configurations in a single frame. Here the battery and the engine alone or together can power the vehicle, and the battery can be charged simultaneously through the engine. Different speed and torque of every component are employed to decide the power delivered to the wheel. The speed and load can be varied to get maximum engine efficiency. The power flow of parallel HEV is shown in Fig. 2.

Fig. 2

Fig. 23.1.2. Plug-in hybrid electric vehicle

Plug-in hybrid electric vehicle (PHEV) comprises of an internal combustion engine and an electric motor. These vehicles are powered by gasoline and have a large rechargeable battery, which is charged up with electricity. The benefits of Plug in Hybrid Electric Vehicles are:

Less petroleum use

PHEV use about 30–60% less oil than conventional vehicle. Since electricity is mostly produced from domestic sources, plug in hybrid reduces the dependency of the oil.

Greenhouse gas emission

Usually PHEV emit less greenhouse gas than conventional vehicle. However, the amount of gas emission depends on how electricity is produced. Nuclear and hydropower plants for example are cleaner than coal fired power plant.

Recharging take time

Recharging with a 120 V household outlet may take several hours whereas with a 240 V, home or public charger it take 1 to 4 h. The fast charge of upto 80% of the capacity take as little as 30 min. However these vehicle do not need to be plugged in. They can only be fueled with gasoline, but without charging, they will not achieve maximum range or fuel economy.

Estimating fuel economy

Environmental Protection Agency provides a fuel economy estimate for gasoline only and for electric only or gas and electric operation both for combined city highway driving as a plug in can run on electricity, gasoline or combination of two.

The largest solar-powered charging station was launched in China in 2015, which is equipped for charging 80 EVs in each day. It also launched a pilot project in Shanghai for testing the ability of the electric vehicle to incorporate sustainable power source with the electric grid. Japan has likewise included more electric charge points powered by solar photovoltaic system than petrol stations in 2015. The top five countries selling electric vehicles as in 2018 are China, European countries, the US, California, and Norway [36]. Several new models are being announced by the manufacturing companies that is likely to be available at low price in the following years. Plug-in electric vehicle has become one of the promising gateways for the reduction of CO2 emission and reduce dependency on the use of fossil fuels.

Many studies were conducted globally on hybrid electric vehicles. Related works presented by Galus and Andersson, 2008 [37] uses an agent-based approach, while Waraich et al., 2013 [38] used micro-simulation for plug-in hybrid electric vehicle based on technical constraints and individual objectives. The model-based non-linear observers (MBNOs) are developed for HEV by Yang et al., 2007 [24] for estimating the torque of permanent magnet synchronous motor. Wu et al., 2016 [25] conducted a study on the stochastic framework for energy management in the smart home by using energy storage of plug-in electric vehicle and photovoltaic power supply. For optimal control, Tesla model S of 85 kWh battery pack and Nissan Leaf of 24 kWh battery pack brings about 493.6% and 175.89% less than those without optimal control. In China, Zou et al., 2013 [39] conducted an investigation on the heavy-duty parallel hybrid electric truck by building up a feed-forward model for examining optimal energy management strategy and concluded that the dynamic programming algorithm improves the mileage of the hybrid-electric truck. In another study made by Hu et al., 2017 [40] in China revealed that convex programming based on an optimal control scheme has an extremely close accuracy to the dynamic programming, which approximately runs 200 times faster. The daily cost of 0.85$ is fundamentally not as much as that in the heuristics PHEV scenario. A similar study conducted by Wu et al.,2016 [41] in Chengdu, China, based on stochastic dynamic programming problem for optimising the electric power allocation amongst utility grid, home power demand, and plug-in electric vehicle battery. Hu et al., 2016 [42] conducted a study in China and found that the capacity choice can be flexible, and the life cycle cost can be improved when there is an advance in fuel cell service life. By using a 10 Ah of Li-battery, their system showed better performance by 1.4% than the existing one. The small and large capacity Li batteries resulted a higher life cycle cost. Bashash et al., 2011 [43] found that the multi-objective genetic algorithm optimizes the charge pattern of a PHEV. It not only minimizes the cost for petroleum and electricity but also the total battery health deterioration over a 24-hour naturalistic drive cycle. The Pareto font of optimal charge pattern is obtained from the results of this optimization. This Pareto font specifies that, for a PHEV to be rapid charged, one should minimize the battery degradation and energy cost. The result is obtained by utilizing an electrochemistry based model of anode-side SEI development in lithium-ion batteries. SEI growth is a prime aspect that governs the degradation of the battery. Hadley and Tsvetkova, 2009 [44] made a study on the impact of penetration of PHEV into the power grid and found that the kind of generation used to recharge PHEV and emission greatly depends upon the time and area of recharge. Kelly et al., 2012 [45] studied on the load profile charging and gasoline consumption of PHEV in USDOT's, National household Travel survey based on driving pattern data. They took the information about 17,000 electric vehicles for tracking their battery SOC for determining timing, quality of gasoline consumption, and amount of electricity for a fleet of PHEV. They also examined the PHEV characteristics based on their charging location, charging rate, size of the battery, and charging time. A similar study conducted by [46] about the challenges and policy option of PHEV into the power grid. Various other studies conducted across the globe on plug-in hybrid electric vehicles are presented in Table 1.

Table 1. Studies on plug-in hybrid electric vehicles.

| Authors | Place and country | Outcome |

|---|---|---|

| Bradley and Frank (2009) [47] | USA | Basic design consideration for Plug in electric vehicle, its architecture, energy storage trade off, energy management system, drive train component function and grid connections are presented. |

| Darabi and Ferdowsi (2011) [48] | USA | The Plug in electric vehicle charging load profile and suggested policies for three charging scenarios in United States are described. |

| Hajimiragha et al. (2010) [49] | Ontario, Canada |

1. An optimization model is developed based on the zonal pattern of base-load generation capacity from 2009 to 2025, of Ontario's electricity-transmission network. 2. The maximum penetrations of PHEVs in Ontario's transport sector are established to find the viability of charging PHEVs during off-peak periods |

| Peterson et al. (2010) [50] | United States cities |

1. Economics of using PHEV using vehicular batteries for storing generated energy at off peak hours for vehicles use in peak hours is studied. 2.The maximum benefit every year is $ 142–249 out of three US cities with no battery degradation cost. |

| Qiang et al. (2008) [51] | China |

1. An adaptive algorithm is used to find the remaining energy of battery in hybrid electric vehicle and to identify the SOC of the battery. 2. The adaptive algorithm has high robust property, noise-immune ability and accurate for use in Hybrid electric vehicle applications. |

| Villalobos et al. (2016) [52] | Borup (Denmark) |

1. Multi-objective smart charging algorithm for Plug in electric vehicle has been presented. 2.This new methodology is helpful to the stake holders as it allows effective integration of plug in electric vehicle in a low voltage distribution network |

| Weis et al. (2014) [53] | United States | Mixed integer linear programming model is created to determine the capacity expansion, plant dispatch, and PHEV charging based on New York Independent system operator |

| Zoepf et al. (2013) [54] | Used random coefficient mixed logic model to model the charging operation at the end of PHEV journeys | |

| Goel & Sharma(2020) | India (Present Study) | This paper discusses the impact of EV and V2G technologies on the distribution system, their benefits, challenges, and their optimisation techniques. |

Vincenzo et al., 2009 [55] estimated the life of lithium batteries used in PHEVs application under vehicular activity and real driving cycles. An aging model based on the concept of accumulated charge for estimation of battery life. Design optimisation of a lithium-ion cell battery pack for a PHEV and BEV is presented by [56]. When the Plug-in hybrid electric vehicle is large enough, then it can be a back up for the excess of renewable energy and stored energy can be used later for driving need or to provide power [57]. The development in the barrier, trends, and economic feasibility of plug-in electric vehicles in the United States and the impact of PEV on a distribution network have been presented by many researchers [58], [59], [60], [61], [62].

3.1.3. Battery electric vehicle

The battery electric vehicle also termed as BEV is fully electric vehicle. It has no gasoline engine, but consists of high capacity rechargeable battery packs that can be charged from an external source. The battery-electric vehicle utilizes the chemical energy stored in rechargeable batteries to run the electric motor and all electronics involved internally. The BEV could not only reduce the carbon dioxide emission from the light-duty vehicle fleet but also reduce the dependency on fossil-fueled vehicles (Andwari et al., 2017) [63].The BEVs are said to hold the largest share in the Indian market, contributing more than 70% trade-in 2017, which is expected to grow in the coming years. Though the BEVs dominated the sale over PHEV in many countries until 2014, there is a rapid growth of PHEV in the last two years, and the sale has gone almost equal with the BEV. In view of sorts of batteries utilized in the Indian market, it can be classified as Lead-acid batteries, Nickel-metal hydride batteries, and Lithium-ion batteries. In India, the state of Maharashtra has the highest selling volume of Electric cars in 2017. There are similar kinds of literature that study the comparative strategy for estimating the SOC and SOH of hybrid and battery electric vehicles [64], [65], [66], [67], [68].The Hinf observer-based fault estimation of battery in HEV application have been presented by [69] and the algorithm for determining the temperature and thermal life of traction motor in commercial HEV has been discussed by [70].

Andy et al., 2010 [71] proposed two steps model that first segments the road traffic and their respective demands into a hierarchy of clusters, in a natural and automatic manner, followed by optimization by using linear programming for assigning the stations to the demand cluster. This work is believed to be useful for city planning, and for designing a refuelling infrastructure in an urbanized area for BEVs. Cuma & Koroglu, 2015 [72] did a comparative review in the estimation strategy and different methodologies used in hybrid and battery electric vehicles. Battery Electric Vehicles (BEVs) satisfy two conditions i.e. an electric motor is powered by a battery that replaces the ICEV and the tank, and when not in use, the vehicle is plugged into the charging port [31, [73], [74]].

The strategy for estimating the SOC of the lead-acid battery has been presented in [75], [76].The traditional methods such as the Open circuit voltage and the Ampere-hour (Ah) counting are examined by [77], [78].The SOC of sealed lead-acid batteries was estimated by using the Fuzzy logic based algorithm [79]. Robat & Salmasi, 2007 [76] determined the SOC online by the locally linear model tree (LOLIMOT) method, which is a kind of neuro-fuzzy network. The hybrid and electric vehicles consider lithium-ion batteries due to their high possessing power, long life cycle, and energy [80], [81].

Based on technology classification, an EV can be categorised by considering their qualities, for example, charging time of the batteries, driving range of an EV, and the maximum load the vehicle can take. The charging time and the driving range are essential attributes that are distress to the customer. Charging time mainly depends upon the capacity of the battery and kinds of batteries employed. The driving range could be as low as 20 km to as high as 400 km for every charge [82].Likewise, the top speed could go up to 160 km/hour in a few EVs, with a charging time of less than 8 h and tends to be higher in some vehicles. In developing countries like India, the hybrid electric vehicle has been a growing interest in recent days due to the significant improvement in EVs. In future, a lot of innovations are expected to change the EV scenario as EV manufacturer look forward to reducing the production cost.

The overview of electric Vr. Hybrid difference is presented in Table 2.

Table 2. Difference between Electric Vehicles Vs. Hybrid Vehicle.

| Electric Vehicle | Hybrid Vehicle | |

|---|---|---|

| CO2 Emission | Low | Medium(50–60% of Internal Combustion Engine) |

| Price Range | High | Similar to Internal Combustion Engine |

| Fuel Usage | None | 40–60% of Internal Combustion Engine |

| Charging | Required | Not Required |

| Equipped Charging facility in India | Low | High |

| Powered by | Electric Engine | Internal Combustion Engine and Electric Engine |

3.2. Battery thermal management system

The use of EV will increase in near future and so priority is given to the need of developing effective batteries. The thermal degradation of the batteries is a big challenge for better BTMS which affect the range of the EV. The main objective of the BTMS is to control the temperature of the battery cell and thus improve the battery life. Li ion batteries are usually preferred for their energy storage in electric vehicle. There are many challenges such as low efficiency at high and low temperature, decrease life of electrodes at high temperature and the direct effect on the performance, reliability, cost and protection of the vehicle and the safety issues related to thermal runaway in lithium ion batteries. So an effective thermal battery management system is therefore one of the most crucial technology for long term success of an electric vehicle. Normally the temperature ranges from 25 °C to 40 °C is the optimal working conditions for the Li-ion batteries. When the temperature of these batteries is higher than 50 °C, it degrades the life of the battery.

3.3. Hybridisation factor

The vehicles can also be classified depending upon their hybridization factor. The hybridisation of vehicles helps in improving the mileage, generally communicated as mile per gallon (MPG) or miles per gallon gasoline-equivalent (MPGe). MPGe can be utilised for Plug-in hybrid electric vehicles, where 33.7 kWh electrical energy is the equivalent to the energy of one gallon of gasoline [83].

The hybridization factor of hybrid or electric vehicle is the ratio of the total power from the electric motor to the total power and is expressed as [31]

Where PEM is the total power from Electric motor and PIEC is the total power of internal combustion engine. HF is 0 for a conventional car, whereas it is 1 for all-electric vehicles.

4. Electric vehicle scenario in India

Currently, the EV market is extremely small in India. The sale of electric cars has become dormant at 2000 units per year for the last two years [84]. But there is a vision for 100% electric vehicle sale by 2030 and since we are in 2020, the compound annual growth rate is 28.12% [85]. India's first electric car Reva (Mahindra), was introduced in 2001, and since its launch, it could able to sell a few units. In 2010, Toyota began Prius hybrid model, followed by Camry hybrid in 2013. Electric buses and hybrid vehicles have been commenced as a pilot proposal in a few cities.

The Bangalore Municipal Transport Corporation recently introduced electric transport on a dense corridor in the city. A survey was carried out in Ludhiana city, which demonstrated that 36% of the existing car and two-wheeler owners were enthusiastic about shifting to electric vehicle [82]. Telengana state Government is also encouraging the use of EVs and announced that the EV owners would not pay any road tax. In 2018, the Telengana State Electricity Regulatory Commission (TSERC) approved a charging tariff of INR 6 for EVs. The TSERC also fixed the cost of service for the entire state at INR 6.04/kWh. Hyderabad metro rail has also signed a partnership with Power Grid Corporation of India Ltd to provide EV charging facilities at metro stations. Hyderabad metro rail will be the first metro rail in the country to have EVs charging stations to be monitored and operated by power grid [86]. Hyderabad Government is also thinking of replacing diesel-run public transport vehicles with electric vehicles. This year, the New Delhi Govt. got approval for setting up 131 numbers of public charging stations in the capital. In November 2018, the Delhi Govt. released a draft policy that is aiming to convert 25% of their vehicles to EVs by offering various incentives and by setting up charging infrastructures in both residential and non-residential areas. This policy is intended to develop a charging point at every 3 km by offering a subsidy of 100% (up to INR 30,000) and waive out the road tax, parking charges, and registration fee for EV by 2023. In Mumbai-Pune highway, a Private firm named Magenta Power is also working for setting up EV charging infrastructure [87].

4.1. Scheme for purchasing electric vehicle in India

Central Govt and state Govt have launched various schemes and incentives to promote electric mobility in India .Some of the schemes are mentioned below.

National Electric Mobility Mission Plan (NEMMP) 2020 was declared by the Government of India to enhance the national energy security, mitigating the harmful effect of fossil fuel power vehicles on the environment and development of domestic manufacturing capabilities (GoI, 2012). The NEMMP 2020 could help with the sale of 6–7 million units of electric vehicles, which in turn could be able to save 2.2–2.5 million tonnes of fossil fuel. The vehicular emission and CO2 emission could be lowered to 1.3–1.5% in 2020 as a result of this new plan. According to this plan, 5–7 million electric vehicles can be deployed by the end of 2020. It also emphasizes the importance of Government incentives and coordination between industry and academia. The Government of India is also making arrangement for 100 GW of solar based power generation by 2022, which could improve the reliability and use of renewable energy that will be helpful for charging stations of EVs.

The Government of India has launched a plan on Faster Adoption and Manufacturing of Electric Vehicle (FAME II) to empower quicker adoption of an electric and hybrid vehicle. This scheme also encourages purchase of EVs by providing various incentives and setting up of charging infrastructures. In February 2019, cabinet cleared 10,000 crore for FAME II for its implementation from April 1st 2019 for a period of three years [88]. The EV manufacturers are eagerly waiting for this single policy scheme to be implemented for creating a roadmap of the EV ecosystem together with charging infrastructure and manufacturing incentives.

Similarly, NITI Aayog's transformative mobility report of 2017 has set a roadmap for using pure electric vehicles following the development of the EVs technology and necessity to reduce energy demand in the automobile sector. It is said that if India adopt transformative solution of shared connected electric mobility,100% public transport vehicle and 40% private vehicles, then it can become all electric by 2030 [89].This vision needs to be spread out to have all electric vehicles in near future.

The Society of Indian Automobile (SIAM) along with other automobile manufacturers aim in achieving selling of hundred percent pure EVs (battery electric and fuel cell vehicles) for intra-city public transport fleets by 2030 [90] .Under this scheme, i) 40% of new electric vehicle sale is expected to put on the market by 2030 and ii) 60% of new electric vehicle sale to employ greener technology like hybrid and other alternative fuel by 2030. To ensure smooth functioning of the scheme, Government, Industry and various stakeholder should come forward to collaborate and invest in long term plan to make hundred percent electric vehicle regime.

5. Barriers for EVs in the Indian market

Barriers for EVs in the Indian market can be addressed from various prospective such as Technical barriers, policy barriers, and lack of infrastructure. These are shown in Fig. 3.

Fig. 3

Fig. 35.1. Market

5.1.1. Vehicle servicing

In order to take proper care of the electric car, a trained technician should be available to repair, maintain, and find troubleshoot of the electric vehicle. They must be able to apply their skills to rectify the problem as quickly as possible.

5.1.2. High capital cost

The battery packs of an electric vehicle are expensive, and also it needs replacement more than once in its lifetime. The gas-powered cars are cheap when compared with electric vehicles.

5.1.3. Consumer perception

Consumer perception plays a vital role in attracting new customer and retains an existing customer. Despite the growing range in the auto market with a broader range of electric vehicles, the choice of buying an electric car is limited and is expected to continue over time. So there should be aware of the company offerings to the customer by means of advertising, social media, or another channel. Studies show that the lack of knowledge associated with the Government scheme, economic benefit, and awareness of the vehicular technology can have a direct impact on the electric vehicle adoption.