1. Introduction

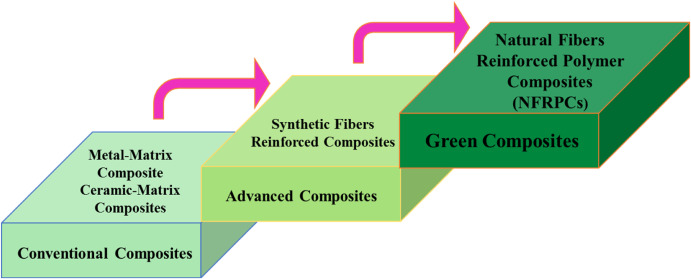

Fundamentally, a material that constitutes at least two different materials is a composite. Bricks, concrete, wood, bone, and manufactured composites such as fiber-reinforced plastics (FRP) would be incorporated in this definition [1,2]. Nowadays, FRPs are applied for the fabrication of different structures, owing to high strength, high stiffness, and the combination of low weight. Usually, they are made of epoxy resin and synthetic fibers [[3], [4], [5]]. These materials are customarily known as high-performance composite materials [6]. The addition of natural fibers (NFs) especially as a reinforcement in composite materials is considered a popular technique for different applications [7], especially in view of sustainable materials. These NFs offer several benefits, for instance, their potential to substitute different synthetic fibers [[8], [9], [10], [11]]. These NFs have also been utilized to produce bio-composites. Fig. 1 depicts the advancements in composite materials. Natural Fibers Reinforced Polymer Composites (NFRPCs) possess different advantages like low weight, biodegradable, less expensive, and exhibit excellent mechanical properties [[12], [13], [14], [15]]. These properties made NFRPCs unique materials for many transportation applications, e.g., aircraft, motor vehicles, construction, and trains [16,17]. The most imperative parts of physical foundations for construction are steel, cement, and timber, which leads to high development costs [18,19]. Oil-based fiber [20] reinforced polymer composites are attractive compared to traditional development materials [21] in the last few years. These NFRPCs are also called bio-composites and further categorized into complete or partial green composites [[22], [23], [24]].

Fig. 1

Fig. 1Nowadays, bio-composites of superior characteristics are fabricated as a result of continuous research devoted to the field of NFs in the last decade [[25], [26], [27], [28]]. Plant fibers, especially bast and leaf, discover applications in auto enterprises. However, a large portion of different NFs [29] are investigated only at laboratory scales and they have not yet proved their ability to be used in engineering applications [[30], [31], [32]]. It is important to consider different types of NFs. The three major types which produced NFs are:

-

1.

Animal-based fibers

-

2.

Mineral fibers

-

3.

Natural lignocellulosic fibers (NLF)

Plant fibers contain cellulose as their primary component, whereas, protein is the essential constituent of the animal fibers. Both mineral-based fibers and animal-based fibers are seldomly applied as reinforcement medias in NFRPCs as compared to plant-based fibers due to their unavailability and high price. Animal-based fibers include wool, silk, feather, and hair. On the other hand, mineral fibers are acquired from the minerals and the most abundantly occurring mineral-based fibers are asbestos and basalt [13,33]. Plant-based fibers are largely obtained from topical areas and agricultural crops. These fibers like sisal, flax, ramie, cotton, banana, and hemp have found their applications in the building and automotive industries due to their low cost, lightweight, superior mechanical properties, and abundance [[34], [35], [36]]. These fibers are of eco-friendly and biodegradable nature that have a positive effect on the environment. Furthermore, these fibers possess superior stiffness and tensile strength than animal fibers and these properties are comparable with the characteristics of synthetic glass fibers. Moreover, animal fibers exhibit inferior hydrophilic properties than plant fibers, highly sensitive to some alkalis and bad conductors of heat. The reinforcement of the synthetic polymers with these fibers produces high-quality composites in terms of their mechanical properties [37]. Few researchers observed that the starting temperature of the degradation of plant-based fibers is 240 °C. Furthermore, cellulosic materials degrade in between 260 °C to 350 °C. Whereas, hemicellulose decomposes within the temperature range 200 °C–260 °C that produces more non-flammable gases. The decomposition of lignin (constituent of plant fibers) starts from 160 °C to 400 °C [8,33].

Moreover, the fiber source, extraction process, accessibility, fiber type, and synthesis method are some of the important features which influence the mechanical properties of NFRPCs. Moisture absorption is also an important parameter that critically affects the overall mechanical properties of NFRPCs [[38], [39], [40], [41]]. Fig. 2 shows the moisture contents at equilibrium in different NFs. Ahmad et al. [42] studied the mechanical properties of hemp/polyethylene terephthalate hybrid composites under different water immersion rates. The results of this study showed tensile and flexural strength continuously decreasing with increasing the moisture rate. Thus, lowering the mechanical properties of the hybrid composites, as depicted in Fig. 3.

Fig. 2

Fig. 2 Fig. 3

Fig. 3It has been perceived that the NFRPCs have gone through critical changes in the last decade. As result of this, these materials are now considered for various engineering and material science applications due to a lot of research devoted to this field of NFRPCs that ought to be updated for comprehending the performance and different attributes associated to the NFRPCs. Thus, this review tries to cover the following important questions related to the performance and selections of NFRPCs (1) Are NFRPCs are environmentally and economically superior to synthetic fibers reinforced composites? (2) Do NFRPCs have higher fiber content for equivalent performance? Thus, reducing pollute-based polymer content; (3) Does the performance of NFRPCs improves through hybridization and chemical treatment techniques? (4) What are the emerging applications of the NFRPCs? To address these challenging questions, an up-to-date review is needed for the better understanding of NFRPCs.

2. Natural fiber reinforced composites

There are two phases of fiber-reinforced composites; one is the matrix, and the other is reinforcement. Wielage et al. [43], Abu Bakar et al. [44], Velde et al. [45], and Bledzki et al. [46] categorized polypropylene (PP), low-density polyethylene (LDPE), polyether ether ketone (PEEK), and high-density polyethylene (HDPE) as the polymer plastic matrices. Paul et al. [47] and Rouison et al. [48] listed some conventional synthetic fibers [49] that include glass and carbon fibers. Generally, plastics exhibit inferior mechanical properties, and their mechanical performance can be improved by the introduction of high-strength materials [50] (fibers) as reinforcement media [51,52].

Historically composite materials are used in many commercial applications. For example, the particles of bamboo shoots were used by ancient people in the mud walls and laminated glued wood by Egyptians in 1500 BCE [19]. The metals were laminated in the making of swords (1800 AD) [53]. Composite materials design, manufacturing processes, and modern technology are increasing rapidly due to high demand, high strength, and environment-friendly nature [54].

Natural fiber-reinforced polymeric materials are captivating the interest of researchers and engineers to be used instead of conventional fibers. It is due to many advantages associated with NFs, which include ease of decomposability, environment friendly, low cost, and low weight [4,[55], [56], [57]]. Based on their usage, the plants that produce NFs, are divided into primary and secondary plants. In primary or essential plants, jute [58], sisal, and kenaf [59] are grown for their fiber content. In contrast, auxiliary or secondary plants (coir, oil palm, and pineapple) are those in which the fibers/strands are created [[60], [61], [62], [63]].

To reduce the material cost, weight and to provide sustainable solutions, natural fiber-reinforced composites have many attractive features, particularly beneficial in plastics, electronics, packaging [64], and automotive industry [[65], [66], [67]]. For consumer applications, the natural fiber reinforced hybrid composites are utilized for interior paneling, household tables, window panels, and chairs [67,68]. These materials can also be a sustainable option in the automobiles and interior paneling of airplanes. Some of the essential properties of NFs found in the literature are presented in Table 1.

Table 1. Properties of different natural fibers [8,27,69].

| Fibers | Cellulose (wt%) | Density (g/) |

Moisture Content (wt %) |

Microfibrillar angle (degrees) |

Young's Modulus (GPa) |

Tensile strength (MPa) | Elongation at break (%) |

|---|---|---|---|---|---|---|---|

| Abaca | 55–62 | 1.5 | 14 | – | 10–12 | 400 | 3–10 |

| Coir | 31–42 | 1.1 | 10 | 30–40 | 4–6 | 106–175 | 17–47 |

| Cotton | 84–91 | 1.5–1.6 | 8 | – | 6–12 | 290–800 | 7–8 |

| Banana | 17 | 1.3 | 7 | 10 | 7–20 | 54–754 | 10.35 |

| Ramie | 67–75 | 1.5 | 8 | – | 61–127 | 400–900 | 1–4 |

| Sisal | 64–70 | 1.45 | 10 | 10–22 | 9–15 | 568–640 | 3–7 |

| Jute | 60–70 | 1.3 | 11 | – | 12–25 | 393–770 | 7–9 |

| Pineapple Leaf | 20–80 | 1.44 | 12 | 8–14 | 34–82 | 413–1627 | 0.8–1 |

| Hemp | 67 | 1.48 | 10 | – | 60–70 | 690 | 1.6 |

Several studies can be found in the literature verifying the excellent mechanical properties of these materials as well as the limitations in their applicability. Venkateshwaran et al. [70] found that NFs reduced the considerable weight of composites. Bisaria et al. [71] studied mechanical properties by changing the fiber length and found that composites of 15 mm length possessed maximum flexural and tensile properties. Ashish et al. [72] found that NFs chosen as reinforcement, can decrease the tool wear and tear during the machining process. A few materials (flour of the wood and shell) are being used in the polymer as a filler to confer the positive benefits in the composites, such as removal of shrinkage and creep resistance in the materials after molding.

3. Sustainability of NFRPCs

NFRPCs are considered one of the emerging materials of the present time and the “green” term is often associated with these NFRPCs [24,30,73]. It is due to the biodegradability of the NFRPCs happens with the breakdown of the individual constituents in composite materials [74]. Biodegradability, recyclability, and sustainability can have a significant effect on the both future as well as present climate [[75], [76], [77], [78]]. Ecofriendly materials are gaining attention throughout the world for continually raising guidelines and enactments against harmful materials. In this context, the researchers are encouraging the production of green materials especially NFRPCs [36]. NFs contribute a huge role in the production of NFRPCs. The production of NFRPCs also consumes lower energy 9.55 MJ/kg as compared to the traditional fiber-reinforced composites e.g., glass 54.7 MJ/kg [79]. The NFRPCs have lower environmental impacts than synthetic fiber reinforced composites. These products equipped with economical qualities like biodegradability, and renewability are raising the market volume especially due to their lower climate effects [80]. Fig. 4 illustrates different parameters associated with sustainable products.

Fig. 4

Fig. 4Furthermore, the significant benefit associated with NFs is revenue that comes from their manufacturing. Moreover, the land for NF creation can be continuously cultivated many times. For example, the manufacturing of flax and hemp fibers further yields seeds, substances and oils with numerous important uses, including that of healthful supplements for individuals [81]. The mass created is also biodegradable toward the finish of its life cycle. For instance, coir strands are already a byproduct of an industry that produces 64.3 billion nuts per year [82].

These NFRPCs mostly contain 60–70 % of NFs and the remaining portion is the adhesive and matrix. In an open climate, the degradation of NFs is affected by environmental dampness, temperature, ultraviolet (UV) light, and the presence of different microorganisms [60,83]. The degradation happens by the breakdown of hemicelluloses, lignin, and cellulose of the fibers. In this way, the complete failure in the mechanical properties of the NFRPCs was observed [84]. The kenaf/POM composites were exposed to dampness, water shower, and UV light in a chamber and the materials exhibited lower tensile strength. This outcome was attributed to the degradation of the cellulose, hemicelluloses, and lignin of kenaf filaments [85]. The impact of the atmospheric condition on the biodegradability of jute/phenolic composites was studied [86]. The reported results showed that almost one-half of elastic properties were reduced after their exposure to the UV for two years. Furthermore, pitch breaking, swelling, fibrillation, and dark spots were also observed due to the UV exposure. Some of the general attributes associated with sustainable NFRPCs materials are presented in Fig. 5.

Fig. 5

Fig. 53.1. Economic perspective

NFRPCs are often known as sustainable materials because the most used materials in NFRPCs are obtained from living plants and sometimes animal's skin. The United States (US) market shares the facts that the composite market was 2.7 billion pounds sterling in 2006 and it is assessed to reach 3.3 billion pounds real by 2012 with a 3.3 % yearly development. Furthermore, NFRPCs market in the US encountered a 13 % development rate (275 million kilograms) between 1994 and 2004 [87]. Furthermore, the interest in NFRPCs continues to rise. The average worldwide yearly market development for NFRPCs was 38 % from 2003 to 2007, while Europe saw the most noteworthy yearly development at a pace of 48 %. This market was assessed at 0.36 million metric tons in 2007 and it is reached 3.45 million metric tons in 2020. Composite materials-based industries are proved to be successful businesses all over the world, nowadays NFRPCs are effectively contributing to these industries.

3.2. Environmental perspective

The ecological benefits of composite materials over the conventional aluminum structures in airplanes have been proved and investigated through different life cycle assessment (LCA) based research. The worldwide progress of the airplane industry with composite design is estimated to contribute 15 %–20 % decrease in CO2 contents till 2050. NFRPCs are more eco-friendlier than traditional composites due to the major contribution of cellulose, hemicellulose, and lignin in their structures.

Cellulose is an abundantly available molecule that decomposes naturally. Furthermore, after serving their valuable life the NFRPCs can be decayed along with different polymers. For instance, the energy-related to burning for China reed strands is assessed to be 14 MJ/kg. Furthermore, this incineration results in no emissions of CO2 in the atmosphere. Thus, the burning of NF composites results in positive carbon credits and lower danger to the atmospheric impact. The global energy requirements (GER) [87,88] in the form of some NFs and residues used for generating energy at the end of their LCA are shown in Fig. 6.

Fig. 6

Fig. 64. Chemical treatments

Different chemical treatments can be adopted for improving the mechanical and surface properties of both metal matrix composites [89] and fiber-reinforced composites due to the fundamental problem associated with NFs known as hydrophilic nature. The NF composites exhibit poor mechanical properties even in hybridization with synthetic fibers [5]. NFs are comparatively more moisture absorbent and exhibit lower strength than synthetic fibers [90]. Researchers are aiming to develop pre-treatment processes to improve the compatibility of NFs with polymer matrices [91] and to enhance the mechanical characteristics of the composites.

The alkali treatment approach is one of the least complex, economical and powerful techniques applied for enhancing the attachment of NFs with epoxy resin. The impact of coupling agent NaOH in alkali treatment had been studied by different researchers [90,92,93]. The results revealed that NaOH concentration (1, 5, and 10 %) and length to submerge the filaments (0, 24, and 48 h) had different consequences on the fiber surface morphology. Mukhtar et al. [94] compared the different chemical treatment procedures on sugar palm fibers. The reported results showed that alkali and sodium bicarbonates treated fiber possessed an increase in crystallinity, thermal stability, and surface roughness compared to the untreated jute fibers.

Silane coupling agents composed of bifunctional structures. These agents are usually employed as chemical enhancers and can make chemical platforms between the fiber and the matrix. Silanes are additionally adhesion promoters in numerous applications and are utilized as substrate primers [[95], [96], [97]]. Maleated coupling agent's treatment is applied to strengthen the composites containing different NFs. The setup job of these agents (MaPOs) is to produce two fundamental elements, practical assembling and the efficient collaboration of maleic anhydride with the useful surface of fiber reinforcements [8].

Acetylation treatment is known as the esterification strategy for strengthening regular or natural filaments. Acetyl gathering (CH3CO) responds with the hydrophilic hydroxyl gatherings (OH) of the fiber and removes the moisture content from the fibers [94]. The different chemical treatments, along with their agents or functional groups are summarized in Table 2.

Table 2. Different chemical treatments and their effects [31,41,98].

| Chemical Treatments | Functional Groups/Coupling Agent | Specific Effects on Natural Fibers |

|---|---|---|

| Benzoylation treatment | Benzoyl chloride | Makes fibers hydrophobic |

| Peroxide treatment | Polyethylene | Improve the adhesion of fibers with a matrix |

| Sodium Chlorite treatment | Sodium Chlorite (NaClO2) | Remove moisture from fiber |

| Acrylation and acrylonitrile grafting |

Acrylic Acid (CH2 CHCOOH) CHCOOH) |

Bonding capacity and stress transfer of the interface increases |

| Oleoyl Chloride treatment | Oleoyl Chloride | Improves wettability and adhesion properties |

| Triazine treatment | Triazine (C3H3N3) | Improves the adhesion of the fibers |

| Permanganate treatment | Potassium Permanganate (KMnO4) | Improves the thermal stability of the fibers |

| Fungal treatment | Specific Enzymes | Enhance the linking/meshing of fibers in the matrix |

NLFs have been used as cost-effective and promising reinforcements media in composites [99]. Their effectiveness can further be increased through chemical treatment or coating with any functionalized materials. For example, Filho et al. [100] studied the novel piassava fiber with and without graphene oxide (GO) functionalized, epoxy composites. Thermogravimetric investigation results showed maximum thermal stability at around 200 °C for the perfect piassava fiber. Furthermore, the hemicellulose and lignin degradation occur at moderately higher temperatures for the GO-coated piassava strands. The differential scanning calorimetry examination revealed that molecular breakage occured at an endothermic peak at around 125 °C for the perfect piassava fiber which was not found for the GO-covered strands inside the most extreme time frame investigated. The dynamic mechanical analysis (DMA) testing showed that outstanding changes associated with GO coatings on the piassava fibers with regard to the viscous stiffness and damping limit of the epoxy composite. In a similar study, Costa et al. [101] evaluated the mechanical properties of composites with and without the functionalization of GO curaua fibers. The results revealed 64 % increase in yield strength, 40 % better tensile strength, and 28 % rise in toughness for GO curaua fibers composites.

5. Hybrid natural fibers reinforced composite materials

The reinforcement of more than one type of material in the matrix forms a hybrid composite that is moderately cheap [102]. There is a possibility that fiber-reinforced polymer hybrid composites have:

-

•

Two types of phases, one is consisting of a matrix and the other is consisting of more than one reinforcing phase.

-

•

Two types of phases, one is consisting of a reinforcing phase and the other is consisting of more than one matrix phase.

-

•

Manifold matrix phases with more than one reinforcing phase.

Previously in many studies, it has been observed that hybridization with any synthetic fibers improves many structural properties of NFRPCs. Venkateshwaran et al. [70] concluded that mostly glass fiber and carbon fiber are responsible for enhancing hybridization's mechanical properties. By adding the volume fraction of glass, tensile strength and Young's modulus were improved due to the better compatibility of the glass fibers with the polystyrene matrix. Ajith et al. [103] found that the polyester composite reinforced with jute fibers exhibited inferior properties than the jute reinforced with epoxy composites. In another study, Sanjay et al. [104] observed that by hybrid reinforcement of jute and glass fiber, the properties of the composites can be enhanced as compared to individual jute or glass fiber reinforced composites.

Khalid et al. [105], Ali et al. [106], and Haneefa et al. [107]observed the combination of different NFs in thermoset plastics. Kiran et al. [108] discovered that banana fiber reinforced with polyester had a tensile strength of about 59 MPa for a fiber length of 3 cm and weight of 51 %. Hybridization is typically categorized into interlaminate and intralaminate. Interlaminate, or basically overlay, obtains by depositing layers made of various strands. Whereas, in intralaminates, the two filaments are entrapped inside a single layer [109].

Sanjay and Yoghesha studied the hybridization effects of different laminate layers consisting of various jute/kenaf/E-Glass woven fabric layers. These laminates were manufactured utilizing the vacuum bagging method. The excellent hybridization results were observed in these laminates in terms of their mechanical properties [110]. Furthermore, the consequences of hybridization for improving the structural, thermal, and mechanical properties of many NFRPCs were reported in many studies [[111], [112], [113]].

Hybridization by adding the laminates of the synthetic fiber [32,96,112,114] can provide NFRPCs of better moisture absorption property along with nobler mechanical properties. For instance, glass or carbon filaments are impervious to moisture absorption and have relatively higher mechanical strength than those of NFs [[115], [116], [117], [118]]. Thus, hybridization through the synthetic fibers accomplishes an agreement between predominant mechanical properties and the cost of the composites. For half-breed fiber composites, the Rule of Hybrid Mixture (RoHM) is a broadly utilized technique that can anticipate Young's modulus of these hybrid NFRPCs [113,[119], [120], [121]]. Nonetheless, the impacts of hybridization on the mechanical degradation instigated by dampness and moisture remain vague [122,123]. Table 3 summarizes the different synthetic fibers and NFs were studied by many researchers through hybridization technique [[123], [124], [125], [126], [127]].

Table 3. Hybridization of NFs with synthetic fibers.

| Natural Fibers | Synthetic Fibers | Advantages Achieved | Ref. |

|---|---|---|---|

| Jute | Glass | Optimum mechanical properties were achieved by utilizing jute fibers. | [128,129] |

| Sisal | Glass | A good tensile strength was achieved by incorporating jute fibers. | [130] |

| Sugar Palm Fiber | Carbon | Experimental results revealed that hybrid composite containing 60% of sugar palm fibers and 40 % carbon fibers possess highest flexural strength. | [131] |

| Banana | Glass | Banana fiber has shown the optimum flexural strength when used with glass fiber. These NFRPCs have found its usage in sports industry. | [132] |

| Jute | Carbon | Impact and flexural strength were found to be increasing with increasing the jute fiber percentage in carbon/jute hybrid composites. | [106] |

6. Emerging applications

Threats related to guns have significantly affected the human life, in particular to the warriors and public soldiers. Multilayers Armor System (MAS) provides effective protection against these threats. Conventionally different synthetic materials like aluminum and Kevlar fibers (Dyneema) were utilized in the MAS. NFRPCs are now considered as one of the most emerging materials for many engineering applications, especially in MAS. These NFRPCs are considered as the second MAS layer [133]. For example, Luz et al. [134] performed a comprehensive study using both NFRPCs and conventional materials (Dyneema plate) in hard armor. These NFRPCs are produced by utilizing pineapple leaves (PALF). The purpose of this hard armor system is to provide extra protection in normal level IIIA ballistic protective layer vests, made with Kevlar. By incorporating the NFRPCs along with the ceramic front panel, results in ballistic protection of level III. The results of this study show that this degree of ballistic protection proved to be effective against 7.62 mm type rifle ammo for the National Institute of Justice (NIJ) global standard for level III security which is equivalent to the Dyneema plate, generally utilized in protective layer vests.

Pereira et al. [135] performed a similar study on polyester composites produced from fique fibers for ballistics testing. Different volume fractions of fique fibers were tested. The results showed that the polyester composites having 30 % volume fractions of fibers are ideal candidates for MAS and can also replace Kevlar due to their high energy absorption and integrity after the impact. Fig. 7 shows the schematic diagram of the hard armor system for ballistics protection.

Fig. 7

Fig. 7Filho et al. [136] evaluated the ballistics performance of NFRPCs utilizing piassava fiber. The composites were produced with 10–50 % volume fractions. Ballistics testing was done using 7.62 mm ammunition. The assessment of the ballistic testing system was estimated by the depth of penetration, which triggers the consistency with the human body, in understanding certain necessities of the NIJ standard 0101.06. The cracked materials were breaking down after the ballistic tests. Finally, these testing results showed that MASs utilizing piassava fiber composites as a subsequent layer provides effective protection. This demonstrates that piassava fiber which is a green material can also be used in armor systems effectively.

Nowadays, a new class of NFs is under extensive considerations. Neuba et al. [137] explored relatively a new class of NF named as “Cyperus malaccensis (CM)”, a type of sedge fiber, which is already consumed in ropes, furniture, and paper.

7. Numerical techniques

Numerical methods can be utilized to model and simulate the mechanical behavior of composite materials, yet the primary ones are Dynamic Relaxation (DR) coupled with Finite Difference Method and Finite Element Method (FEM).

7.1. Dynamic relaxation method (DRM)

DRM was first introduced by Rushton [138] and Cassell and Hobbs [139] in 1960. In the dynamic relaxation method, the equilibrium equation is converted into the dynamic equation. The damping term is expressed in the finite difference, and the solution is obtained through the iteration process. The time increment and the optimum damping coefficient are used to stabilize the solution. The specimen's stiffness matrix, applied load, boundary conditions, and mesh size are the main variables that affect the solution.

7.2. Finite Element Method (FEM)

Nowadays, FEM is the most widely used numerical method [140]. Many engineering analysis problems are solved by this numerical procedure [115,141]. It is divided into two primary subdivisions:

-

•

In the first subdivision, discrete elements are used to acquire the member forces and joint displacements of a structural framework. This formulation is known as matrix analysis of structures, and the results obtained are identical to the classical analysis of structural framework.

-

•

In the second subdivision, continuum elements are utilized to acquire estimated solutions to thermal, mechanics of fluid, and the mechanics of solid problems. This approach is an accurate FEM, and calculated results of the required constraints at exact points (nodes) are obtained.

Both types of problems can be solved in a general finite element. The distinct part and the array element interpretations are denoted by the ‘Finite Element Method’. Unarguably, the most accurate numerical method, FEM is used as a computational method for solving the problems that arise in many engineering and material science fields. It is grounded on the concept of replacing any continuum with an accumulation of finite elements with definite force, displacement, and material relationships. Whereas it may not be possible to derive a closed-form solution for the continuum, approximate solutions can be derived for the element accumulation to replace it. Using ideas from interpolation theory, estimation functions or estimated solutions are made, and therefore, they are referred to as Interpolation Functions. Previously adopted numerical techniques on NFs with their accuracy are reported in Table 4.

Table 4. Accuracy of some recently adopted numerical models for mechanical properties characterization of NFRPCs.

| Natural Fibers | Hybridization with any synthetic fibers | Testing type | Maximum Accuracy of Numerical Method | Ref. |

|---|---|---|---|---|

| Jute | Carbon fiber | Tensile | 92 % | |

| Basalt | No | Compressive, splitting tensile, and bending | A very high correlation coefficient was found between experimental and numerical results. | [142] |

| Banana | Glass fiber | Flexural | 88 % | [132] |

| Hemp | No | – | Curing behavior and was successfully predicted through numerical techniques. | [143] |

| Jute | Carbon Fiber | Flexural | 84 % | [106] |

| Flax | Glass fiber | Impact | 94 % | [144] |

| Jute | Carbon fiber | Impact | 96 % | [106] |

7.3. Comparison between FEM and DR

Aalami et al. [145] discovered time requirement by the computer for the DR analysis is approximately eight times lesser than for the FEM, whereas the DR analysis storage capacity, is less than for FEM. Putcha et al. [146] and Turvey et al. [147] noticed that FEM demands large storage capacity and computer time. FEM is more efficient than the DR Method because of the large computations. Aalami et al. [145] discovered that FEM is 15 % more accurate than DR. Therefore, FEM is considered acceptable accuracy. Whereas, DR method is applicable for limited geometries only. On the other hand, FEM can be applied to different complicated geometries and shapes.

8. Conclusion

For lowering the harmful effects of advanced materials on the environment the complete degradation of the materials is necessary and quite challenging at the same time. For this purpose, researchers should consistently search for those materials which are completely combustible or biodegradable. We conclude that these NFRPCs are superior to the synthetic fiber reinforced composites due to the following attributes: (1) These NFs are present abundantly in nature which makes them cheap and sustainable materials (2) There are different techniques like chemical treatments, coating of different materials on NFs and hybridization technique which enhance the mechanical and physical properties of NFRPCs. (3) NFRPCs are best suited to ballistics applications due to their high-impact properties. (4) The environmental effects of NFRPCs are quite low which makes them suitable for various sustainable engineering applications (5) Numerical tools could be a useful tool for the mechanical characterization of composite materials. Prediction of mechanical behavior of materials using numerical tools could allow the design of innovative and novel materials. These numerical techniques proved to be both times saving and environmentally friendly.