1. Outlook

Plastic, the most pivotal material has been originated to be tough, light in weight, chemically and physically molded, resistant to degradation to be utilized in packaging, construction, transportation, and industrial sectors. Consequently, the manufacturing of plastics is progressively escalating and since 1950, approximately 8,300 tons of plastics have been fabricated (Geyer et al., 2017). Eliminating the utilization of disposable plastics and transformation towards the discoid economy of plastics is the utmost dismay worldwide. It is explicit that there is the sight of exigency and exacerbation of plastics as environmental havoc by industrial sectors and regimes, and this aforementioned cornerstone is underpinned by science. Additionally, there is a perforation in the documentation exhibiting the perspective of mankind towards plastics that edict rumination. This enormous quantity of plastic wastes is frightening our soil environment, freshwater, marine system, and probably the welfare of the whole food chain network. While plastics are pervasive in day to day life, eradicating pollution of plastics entails pace from all possessors to invigorate more sustainable utilization of plastics. E.g. reduction in consumption and curtail on plastic wastes should be taken into deliberation. It should become obligatory for industries to design plastic products that are environmentally benign throughout the biological clock (MacArthur et al., 2014). Due to the imprudent implementation of plastics, there has been an 8.4% annual compound growth rate of production that reached approximately 348 million metric tons in 2017. An estimated amount of 8.3 billion metric tons has now been produced (Kelly, 2017). Think this reckon for a while, the surface area of the earth is 5.10 × 108 km2, for every square kilometer 1.6 metric tons in another word small water bottle for every square meter (at 0.98 g/cm−3 density which is equal to a rigid plastic sphere above half of the kilometer in dia) turning into a plastic space station (Gibb, 2019).

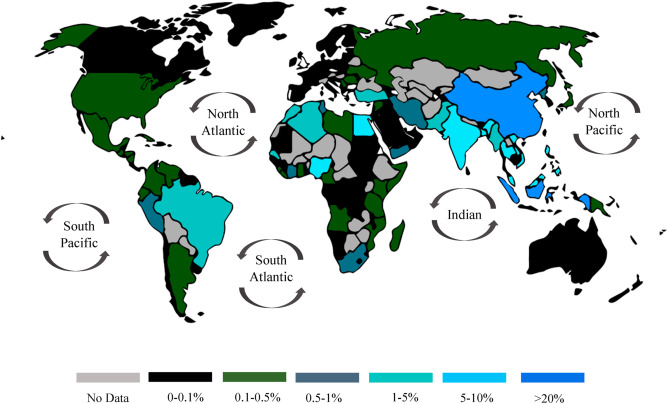

It was evaluated by the world bank that the generation of plastic wastes globally in 2025 will jump to 9–13% of total municipal solid waste which varies from country to country. Fig. 1 depicts the predicted global mismanaged plastic in the year 2025. To eradicate the unpropitious effects of plastic waste, attempts have been made in fostering the recuperation of plastic waste for recycling (Brooks et al., 2018). Europe is the only continent recovering 50% of generated plastic waste, the rest is dumped into landfills (Mincer et al., 2019). Howbeit, recycling plastic wastes is presently more exorbitant than incineration and landfilling techniques. Therefore, more alternatives having economical utility are required to enhance the inclusion of private organizations for recycling plastic waste. The major stumbling block of the plastic sector is single-use plastics utilized in the packaging of beverages, tobacco, food, etc. Hence in 2017, 348 billion metric tons of plastic were produced in which the major contribution was of single-use plastic products i.e. ~40% usually composed of polypropylene, low and high-density polyethylene, polyethylene terephthalate, etc. These polymers are extensively used despite poly (vinyl chloride), polystyrene, polyurethane, etc.

Fig. 1

Fig. 1Fringe benefits for end-users from the primacy of cost, energy efficiency, and convenience that single-use plastics bestow. But utilizing artifacts like plastic bottles, carry bags, straws, and utensils, etc are need to be disposed of properly by the consumers. As we know, a range of plastic items is fabricated to be utilized only once, providing benefits beyond cost savings, gratification, and eventually assisting public robustness e.g. products that avert the unfurl of infections are pivotal in the medical sector. Medical appliances like drug tests, syringes, bandages, etc are ordinarily created to be disposable. Noticeably, many of these single-use plastics are not fabricated to be reused and because of their configuration, some can't be recycled by using conventional techniques. This results in dumping into landfills, littering which causes appalling conditions for the environment and welfare of human beings.

Recently, China has actuated the elimination of global recyclable plastic wastes. Besides, Australia ought to forbid the export of materials and escalate the domiciliary processing. Due to the crucial pace by China, many countries are in the vexation of dealing with their plastic dross. In some whereabouts, plastic wastes have been dumped into landfills or piled up, and fire at recycling spot triggered the environmental menace. Fig. 2 is displaying the annual outcome of plastic wastes in billions of pounds in top-ranked countries. In Europe, despite the elevated lucrative importance of the plastic industrial sector, the recycling province of plastics remains imploded or underdeveloped attributed to the multitude of hurdles that have been discerned in belles-lettres including technological, regulatory, and organizational barriers as reported by (Henlock et al., 2014) and (Plastics Europe & EPRO, 2016). Rickety waste management implementation usually results in discarded plastic wastes in the environment thereby it is frequently dumped into oceans as marine dross (Osborn and Stojkovic, 2014). Fig. 3 exhibits the top 10 countries that discarded their plastic wastes in oceans. Amidst them, China has been dumping more than 2,400 tons of plastic wastes in oceans which could be a crucial commination to biota.

Fig. 2

Fig. 2 Fig. 3

Fig. 3China was the predominant destination for plastic. The nation either directly or via Hong Kong, has bought approximately 72% of all plastic waste. By doing this repeatedly, it has emerged out clearly that this is not imperishable (Brooks et al., 2018). In 2013, China has contrived the “Green Fence” program, this policy focussed on enhancing the plastic waste quality they were obtaining. Besides, this blueprint aimed to truncate illegal foreign trading and smuggling. Subsequently, in 2017 China has promulgated a constant ban on the importing of plastic waste which is non-industrial (Raine and Pluchon, 2019). At the beginning of 2018, this remit the market into mayhem, which in turn had a “positive impact on culminating single-use plastics but simultaneously had a negative impact of redirecting the entire industrialized nations wastes”, either to domiciliary incinerators or the other Asian countries despondency incompetent for doing whatever one wants with the plastic waste instead of dumping it inadequately. Contemplating that China has a reasonably high waste plastic management framework, still approximately ~1.5 million metric tons of waste dumped into oceans yearly from its coastline (Jambeck et al., 2015). Nowadays, other countries taking the plastic wastes are far leakier. Consequently, the response to the inquiry as to where all the single used plastics (i.e. polyolefins, polyesters) go is elementary i.e. “Everywhere”.

Keeping the aforementioned statistics into consideration, this review will bestow an insight into the conversion of plastic wastes into futuristic products to be employed for applications like energy recovery, fuel, construction, building components, etc. Endeavors have gone into designing recycling propositions to procure value from plastic waste. In some instances where recovery of valuable raw materials to be utilized in the production of new but similar plastics is plausible, in other recycling instances, plastic waste is directly transformed into products with high added value. Either way, this kind of innovation could be the route to close the material loop of the economy, reducing the need for plastics disposal and demand. Furthermore, the bone of contention revolves around recycling would also be discussed in detail. Easily recyclable plastics oftentimes are in dearth of characteristics that would make them comprehensively useful. So, will the plastics loop close? While the repurposing process of plastics with the prime aim of improving the circularity of material and energy flows is imperative, it is also critical to design plastics that are derived from renewable sources and could potentially biodegrade, moving towards an environmentally closed circular system. Concurrently there is a need to change from our current linear production model based on production, use and disposal to a plastic circular economy model.

2. Plastics are perpetual

Well, this is deftly perceived that plastics are perennial because of their appropriate properties for a wide spectrum of applications. It is tough to reckon any domain of existence that has not been immensely perpetrated by plastics. Undeniably, life appears inconceivable without plastics. In Fig. 4, the production of plastics allocated by a range of sectors has been reported. The packaging sector has been presiding among other utilization with 42% of plastics. Building and construction parts became the second-largest by utilizing 19% of plastics. While the utilization of plastic is intrinsic to vogue and has brought colossal benefits to various sectors include telecommunications, medical devices, and food packaging, etc. It is prominent that ongoing disposal and end of life management approaches are not prolonged sustainable. In Fig. 5, the life cycle of a plastic product from the manufacture to the end of life is represented. Several exemplary initiatives have been knocked to proffer a riposte. For raw materials of plastics, approximately 4% of fossil fuel has been utilized which is extracted annually and it is a low-value gaseous fraction or liquid fraction of natural gas from petroleum refining which is mostly employed to produce plastics (Steensgaard et al., 2017). The stipulation for energy, carbon emissions, and fossil fuel by industry will proliferate by an increase in end-user demand for plastics. Plastics have inherent properties to be reused, recycled several times attributed to the quality of waste fraction recovered by preserving their functional properties and worth; thereby contributing to the development of the circular economy. It is relatively mundane to extricate additional value from end products via the recovery or recycling process. Howbeit, this is ordinarily not reflected in the mechanisms of market regulation, pricing, product design (Rybaczewska-Blazejowska and Mena-Nieto, 2020). Therefore, this bone of contention entails a comprehensive outlook all over the value chain of production of plastics, end of life, and its use.

Fig. 4

Fig. 4 Fig. 5

Fig. 5The gospel that the termination of service life was never in the prototype of plastics which means nano and microplastics can be originated from walruses, mussels, and zooplankton. It is not an eye-opener that contamination in the air we respire, on land we stroll are now converting into feces as concluded by (Gasperi et al., 2018) and (Silva et al., 2018). However, the repercussions of plastic wastes are much wide than this. The generation of plastic waste also acts as a disease transporter, it can foster pathogens using microbial colonization insinuating the outburst of diseased corals. Therefore, when coals come with the contact of plastic waste, the plausibility of disease escalated from 4% to 89% (Bidegain and Paul-Pont, 2018). A report by SAPEA mentioned that “the foremost affirmation propounded that nano and microplastics do not create an omnipresent threat to biota or human apart from small pockets. Nonetheless, that corroboration is limited and the scenario can alter if pollution sustains at present rates”. However, this all reminiscent is of the duration when the initial manifestation of the torment of smoking cigarettes turned up (Alberg et al., 2014). The proliferation in the unfettered rate of plastic wastes into the environment will firmly have a horde of calamitous impacts on life in the same way as smoking does.

Plastics may set foot in the environment at a range of sizes owing to the wide area of applications. Macroplastics are extricated into the environment initiate to degrade steadily into very smaller particles. Nevertheless, nano and microsized plastics are currently utilized in products like media paints, cosmetics, biomedicine, agriculture, etc. Yet the assessment of the utmost peril of nano and micro-sized plastics to the human health requisite comprehension of environmental levels and traverse of vulnerability.

3. Coherence for the worldwide blueprint of plastics

Various approaches to mitigate plastic wastes have been opted. Apprehension is ascending regarding the utilization, accumulation, and disposal of plastics in natural habitat and landfills. Entanglement or ingestion in plastics and percolation of chemicals from products made by plastics can infect humans, marine, or wildlife. Presently, there is worldwide solidarity that plastics are commination to biota which coaxing many incumbencies to proscribe single-use plastics including India, Australia, USA, Kenya, Hamburg, Montreal, Taiwan, Morocco, U.K, France, Zimbabwe, and Rwanda. Management of plastic waste practices globally is pyrolysis, incineration, recycling, landfilling, etc. Plastics can be recycled up to six times. Ordinarily, recycling of waste includes pyrolysis (Fig. 6), mechanical or feedstock recycling:

-

(i)

Recycling by mechanical ways analogous to plastic waste reprocessing to fabricate new products.

-

(ii)

No emissions of greenhouse gases are the repercussions of the process of landfilling, thereby no fringe benefits and no valuable resource waste (Pilz, 2014).

-

(iii)

Options of energy recovery are utilized to produce steam, electricity, gasification, solid refuse fuel, cement kilns, pyrolysis, or heat. Plastics that are highly mixed e.g. automotive, electronic, electrical residues are the intrinsic candidates.

-

(iv)

A recycling approach i.e. pyrolysis comprises catalytic or non-catalytic thermal methods. Pyrolysis of plastics with high temperatures is peculiarly preferable for metallurgical techniques such as the thermoselect process, blast furnace, core process (Devasahayam et al., 2019). Jumbled plastic waste is transformed into monomers, fuels, char, liquid fuel, and other valuable products like combustible gases, hydrogen chloride, carbon, etc.

-

(v)

Recycling via chemical routes can be classified into two major conversion processes which are catalytic and thermochemical catalytic processes. Feedstock or chemical recycling disintegrates contaminated, heterogeneous, and tough to recycle polymer waste into further chemical constituents which converts them into monomeric units to produce novel plastics.

-

(vi)

Gasification of plastics can be done at ~525–625 oC which is much nearer to steel melting temperature.

-

(vii)

Depolymerization via thermal means converts waste plastics into crude oil under high pressure and temperature (4 MPa and >400 °C) in the existence of H2O through hydrous pyrolysis. Polymers having long chain depolymerizing into monomers of short-chain. Gaseous molecules such as carbon dioxide or methane cannot be transformed into oil utilizing this process. In the aforementioned process, the toxicity of organic toxins has been decreased due to the disintegration of chemical bonds. Elimination of heavy metals from samples takes place as stable oxide or ionized forms.

Fig. 6

Fig. 6Notably, one should contemplate the plastic waste reclaimed from municipal solid waste, which is paradoxically large in quantity and usually intended to dump in landfills. On that account, conventional recycling techniques dependent on incineration or mechanical process which are downcycling strategies: they ordinarily lead to materials with nether values contrary to the corresponding original plastic or incompetent energy recovery in the heat form (Rahimi and Garciá, 2017). Recycling plastic waste by catalytic technique is not even implemented on large scale but has a manifest significant covenant. For instance, recovery of bis(2-hydroxyethyl terephthalate) takes place in presence of an excess amount of ethylene glycol and guanidine catalyst followed by thermal treatment of recovered polyester (Matsumura et al., 2008). Therefore, such a type of material could be utilized for synthesizing high quality PET. Undoubtedly, the characteristics of the catalytic process rely on the chemical characteristics of plastics to be converted. Hence, strategies that are contiguous to the crude oil refining may be obligatory for inert macromolecules e.g. polyolefins. The aforementioned processes when directed in non-selective convention can impart hydrocarbons mixture which can perceive application as auxiliary fuels. Nonetheless, enhancing the degree of selectivity, value-added materials can be targeted. Conversion of plastics is not a constricted domain of research if one focuses on the variance of plausible strategies. Apart from organocatalytic and heterogeneous methods divulged above, biocatalysis is additionally withstanding for its array. Enzymes manifest very captivating activity in the degradation of plastics. Latterly, researchers of japan were isolated discrete bacterium from myriad microbes confined in the recycling of PET domain which attributes to the hydrolysis of PET constituting two competent enzymes (Yoshida et al., 2016). Furthermore, such a community of enzymes is anticipated to take part as an essential role in the evolution of conventional upcycling strategies in the future.

3.1. Recycling of plastics: the bone of contention

At this juncture, the skeptical readers reckon that recycling (Simon, 2019), upcycling (Hahladakis and Iacovidou, 2019), and reclaiming (Eriksen et al., 2019) has some hope attributes to the economic restraints, explicitly in the brightness of current utilization once and abandon paradigm. Although viable observations have elucidated that paradoxically implementing existing strategies such as conventional mechanical recycling and catalytic pyrolysis-economical fringe benefit can be consequential as potrayed by (Al-Salem et al., 2017), (Meys et al., 2020), and (Vollmer et al., 2020). McKinsey has lately published a report stating that if recycling depends on current approaches then margins of approximately 60 billion US dollars for the petrochemicals and plastic domain would be implemented to 50% of plastics globally, in which no way withal 12% is presently valorized (McKinsey Center & Ocean Conservancy, 2015 and Conservancy, 2015). Headway for more coherent and logical catalytic conversion strategies for recovering plastic waste is consequently an exhilarating window of opportunity for pedagogue practitioners. Furthermore, it is anticipated to additionally enhance the profitability of the province following the principle of the circular economy, fine chemicals, monomers, and building blocks acquired in this approach which can further be conferred to the fine chemical and polymer industry.

Recycling is turning the norm but the advantages of recycling plastics far outbalance the limitations. The primacy of recycling does make it a paragon for plastics. Howbeit, the limitations must be envisaged also:

-

(i)

Environmental aftermath: Every remnant of recycled plastic can pose severe commination to the biota. The recycling strategy of plastics evolves organic compounds and volatile organic content. These fumes could be pernicious to the animals and plants in the vicinity of recycling plant units. Besides, the acme of heat required to flux plastics will produce carbon emissions which promulgates global warming (Salhofer et al., 2021).

-

(ii)

Downcycling: Ample plastics being recycled are forsooth being down-cycled. This takes place when the plastics are broken into fragments and utilized as discrete and barely competent products in place of new containers. Plastics that are down-cycled may be utilized as plastic furniture or artificial turf. Wherefore, there is abundant waste generated when down-cycled (Hagnell and Åkermo, 2019).

-

(iii)

Stumbling block in health: Aforementioned volatile organic content emitted can proffer a parlous threat to a personage who comes in contiguity of recycled plastics. Plastic resins leech into food which comes from petroleum resources that are stored in plastic resin containers. Plastics are not specified by the Food, Drug, and Administration of the U.S as a crucial menace since solely a small amount of recycled plastic is utilized when generating packaging and food containers. However, the number of chemicals that utilize consumption can expand rely on the kind of plastic, the temperature, and the age of the plastic such as heating in the microwave (Salhofer et al., 2021).

Apart from the aforementioned limitations, recycling of plastics bestows several lagniappes mentioned as follows:

-

(a)

Natural and energy resources can be conserved: Following the recycling of plastics, the quantity of natural and energy resources accorded to furnish novel plastics is appreciably diminished. Production of plastics reconciled around 4% of consumed energy and approximately 70% of plastics manufactured in the US are produced from domestic natural gas (Geyer et al., 2017).

-

(b)

Recycling of plastics is passably a duck soup: Across the US, there are several plastic recycling strategies and approximately 80% of Americans are apt to ingress recycling schemes indisputably. Several municipalities purvey curbside pickup of plastics or recyclables. Various grocery outlets now impart recycling collection of plastic bags that are utilized besides plastic wrap.

-

(c)

Recycling of plastics preserves landfill space: Landfills are turning profusely overcrowded. Recycling is inception to take the moderate burden off of landfills and permits the reuse of plastics in developing novel products (Klemeš et al., 2021).

3.2. Atrocities of microplastics

Microplastics are the never-ending allegory. Even with the ordinary apprehension that micro or nano plastic particles can be originated in various environmental sections (seawater, soil, sediments, air, fresh water), the present perception of implications of these particles at different levels found in the biota can nonetheless be considered meager. The complicated nature of these particles attributes to the synthesis, residual monomers, additives, catalyzing agents, polymeric chains allied with a broad range of plausible surface functionalization; shapes and sizes make the investigation of their factual impact a donnybrook (Rist et al., 2018). Besides, once exposed to the atmosphere due to its high aspect ratio and surface hydrophobicity; they may concentrate and adsorb other contaminants such as metals, pesticides, polycyclic aromatic hydrocarbons which further serve as the bearer of micro-organisms that adhered to their surface (Hong et al., 2017). Following the ecological impacts, the existence of microplastics in coastal zones may also have substantial economic and social impacts. Furthermore, aquacultures, fishermen, restaurants may also agonize economically, if native seafood is adulterated with microplastics capitulating reduced revenue and consumption. There is no solidarity on how to resolve the issue of particles that hitherto exist in the environment. Nevertheless, steps must be taken to curtail the formation of microplastics, and environmental release in view to simply cease plastics does not seem a viable elucidation (Michels et al., 2018).

Corrective measures may be employed at various levels, from consumer usage, production, increased recycling rates, and selection. Improvising waste infrastructure, handling, and waste disposal are also effective measures. At the end of their useful life, recycling, repurposing, and reusing plastics can reduce the issue of plastic debris. This may be attained via economic stimuli such as deposit refund schemes of consumers for packaging and drink containers and benefits in the tax of industries for reutilization of plastics as raw material. To jetton the worldwide environmental challenge and to attain sustainable solitary behavior, interdisciplinary attempts have to be produced to perceive the processes beyond etiquette and key factors enkindle these challenges, prognosticated their evolution over time, and ultimately altering the system adequately to mitigate antipathetic outcomes (Klöckner, 2013). Environmental education should be entrenched in civilization pointing at preventing littering practices and reducing consumption which utilizes mass communicative instruments. The prerequisite of these worldwide actions is several therefore populace must be scrupulously informed about available alternatives and known risks. Effective strategies like utilization of alternatives to plastics like usage of water bottles made up of biodegradable polymers and utilization of glass materials to microwave or store food and to employ bags made up of materials like cloth could be adopted.

The legislative framework could also help in assisting the ocean pollution due to plastics mentioned as follows:

-

(a)

The principle of “Polluter pays” introduced by the Directive of Waste Framework (2008/98/EC) and the presumption of plastics handling should contemplate four Rs (Recover, Reprocess, Reduce and Recycle); by the end of 2018, the commencement of plastic bag tax and (EU) 2015/720 Directive amended the framework for packaging waste and sound management of packaging established by (94/62/EC) European Directive of packaging waste and packaging which focussed on minimizing the consumption of carrier bags made up of light plastic weight in EU.

-

(b)

The recent modification in the development of the EU (2018/0172) Directive following the single sue plastics ban that will modulate the utilization or production of specific types of plastics and implement corrective measures to sovereign state people to minimize the quantity of plastic waste in oceans.

-

(c)

To eliminate illegal dumping, the international convention for pollution prevention (MARPOL 73/78) from Ships; strategies for accountable waste generated from the ship, and management of cargo residues fortify sufficient facilities of port reception which are accessible to meet the exigency of users established by EU Directive (2000/59/EC targets) of Regulation of Port Reception Facilities 2003).

3.3. Biological clock of microplastics

Regardless of the primary and secondary sources, the pattern of microplastics is lingering. It is viable to corroborate the preponderance of synthetic products that exist in our day to day lives perceive their way into water and oil reserves. Nonetheless, unlike further degradable substances that abide decomposition and re-integrate the base chain as nutrients, microplastics are weathered into smaller fragments or plastics that are non-degradable, up to it is just about paradoxical to ratify its existence. Nevertheless, they are doubtlessly to continue their toil impacts in biota. The bijou the particles of plastics, the facile it is to be incorporated or ingested via a broad

Range of micro-organisms and thereby enter into the cells. Therefore, they may exist as foreign bodies directing to continued and consistent inflammatory procedures which may alter cellular viability and eventually lead to necrotic and apoptotic mechanisms. Additionally, another implication for the inefficacy of defecate microplastics is the amalgamation in the food chain that might perceive its way into mankind. Other strategies are required for unconventional single-use plastics. Besides, individuals can unambiguously circumvent as many single-use plastics as they can.

-

4.

The burgeoning of implementation of feedstock for the fabrication of value-added materials.

Conversion of plastic is not a constricted domain of research if one solitary contemplates at the array of feasible approaches. Inevitably, the substitution and reutilization of plastic material are presently vigorously stimulated, as sustainable and efficient recycling strategies prevail rather elusive (Huysman et al., 2017). Furthermore, accessible recycling approaches have not cost-efficient and hence produce a lower quality of polymeric materials results in trammeling the evolution of the circular economy (Sheldon and Norton, 2020). Consequently, the advancement of ineffective processes of recycling within the strategy of the circular economy is paramount, preferably constructing not just monomers for the development of novel plastics but also intermediates or value-added products for further supply chains (Simon, 2019).

3.4. Frontiers in the conversion of plastic waste into fuel

The conversion techniques of plastic waste into fuel depends on the properties and the type of plastics to be earmarked that might be utilized in the process. Furthermore, efficient conversion entails expropriating strategies to be stipulated following the social, technical, conventional economic, and environmental characteristics (Jha et al., 2021). Ordinarily, the transformation of plastic waste into fuel needs feedstock that is combustible and non-perilous (Das et al., 2021). The plastics composition utilized as feedstock may be discrete and articles of some plastic might hold unwanted substances like flame retardants, plastics having nitrogen, halogen, sulfur, etc which has an inherent menace to mankind and the environment (Ibe and Kodera, 2021). On that account, the crucial quality factors when transforming plastic waste into fuel resources are mentioned as follows;

-

(i)

Facile feeding into conversion equipment: Plastic waste is exposed to various chemical pretreatment processes to assist the efficient or smooth treatment during the ensuing transformation process, former to its conversion into fuel products.

-

(ii)

Efficient transformation into fuel products: Thermoplastics behave as binders that manifest briquettes or pellets by adhering or melting to various non-melting materials like wood, thermosetting plastics, and paper in the production of solid fuel (Fraga et al., 2020). Even though, utilizing pelletizer wooden materials are converted into pellets, plastics mixing into paper or wood perplexed the preparation process of the pellet. To fabricate pellets from combustible waste and other thermoplastic materials, appropriate heating is entailed. For the production of liquid fuels, thermoplastics having liquid hydrocarbons can be utilized as feedstock. Therefore, the yield of the product and processing rate could be determined by the type of plastic which is being used. Consumption of energy can be enhanced by moisture presence and contamination of unwanted substances which facilitates the formation of the by-product in the production of the fuel process.

-

(iii)

Clean fuel gas and well-controlled combustion for fuel consumer facilities: To ameliorate the efficiency of heat recovery, it is essential to counterpart the quality and type of fuel to the burner. For instance, the composition of flue gas and the quantity of produced ash are affected by the contamination of inorganic species, nitrogen, and chlorine. It must be nonchalant that the composition of flue gas complies with the regulations of conventional air pollution when utilizing fuel from plastic waste. Therefore, if there aren't any pertinent regulations, to reduce the environmental impact both producers and consumers of recycled fuel should influence the emissions and fuel quality at combustions (Phanisankar et al., 2020). Table 1 displayed the classification of the range of polymers that can be utilized as feedstock for fuel production (Mangesh et al., 2020).

Table 1. Range of polymers utilized as feedstock for the production of fuels.

S. No Polymer Type Examples Illustration 1. Polymers consisting of oxygen PVA, phenolic resins, polyoxymethylene, and PET They have a lower value of heat in contrary to other plastics 2. Polymers containing hydrogen and carbon PE, PP, and PS (Thermoplastics are melt to produce solid fuel assorted with different combustible wastes followed by decomposition to produce fuel) Production of fuel by using conventional feedstock attributes to the clean exhaust gas and high value of heat 3. Polymers consisting of halogens like chlorine, bromine, fluorine, etc PVA, PVDC, flame retardants having bromine and fluorocarbon polymers Corrosive flue gas and hazardous sources upon combustion and thermal treatment 4. Polymers consisting of nitrogen or sulfur PA, PU, and PPS Fuel obtained from the mentioned category of plastics is the source of obnoxious components in flue gas such as SOx and NOx. In exhaust gas, to eliminate the emission of precarious components cleaning of flue gas is obligatory.

Altway et al reported the optimization of liquid products via refinery distillation of bubble cap plate column. The prepared fuel is based on the difference in liquid fuel which is dependent on pyrolysis temperature and the analysis of condensate. The fuel obtained from this method can be utilized for transportation or engine as kerosene and gasoline (Thahir et al., 2019). Rapsing and co-workers investigated the plastic oil converted fabricated by using plastic waste by opting for the pyrolysis technique (Rapsing et al., 2016). The efficiency of conversion was found to be nearly 78.1% with reduction efficiency of waste was 94.3% by having 883 ml oil/kg recovery oil. Kumar et al provided the design for the conversion of plastic waste into oil for conventional purposes (Shukla et al., 2016). In this work, PE, PP, or plastic carry bag wastes are converted into oil by using stainless steel container, electric heater, insulating material layer followed by missing hydrocarbon gas, mixed oil, and carbon black charcoal. Hossain et al examined the conversion of biofuel from plastic waste (Md. Akram Hossain, 2004 Akram Hossain et al., 2004). The devdaru seeds i.e. solid biomass waste converted into pyrolytic oil using fixed bed reactor (liquid collectors and liquid condensers) into consideration which further includes cow dung, charcoal, and rice husk.

3.4.1. A. Propitious conversion of plastic waste into energy recovery

In plastics, the postulation of recovery can also be broadened encompass energy, where material's calorific value is employed by controlled combustion as fuel; however, these outcomes in a slighter gross environmental performance is contrary to the recovery of material as it does not minimize the stipulation of novel (virgin) materials. It is also entirely viable for the same polymer to cascade via several stages-e.g. concoct into a reusable vessel which once infiltrates into the waste stream is recycled and collected into imperishable applications that when turning waste in its pivot, is recuperated for energy. The proficient technique to recover energy content from plastic is incineration. The utilization of recovered energy can vary noticeably depending on whether it is utilized for combined power or heat, generation of electricity, and solid refuse fuel for cement kilns or blast furnaces. Strategies for energy recovery may be the utmost appropriate way of conducting vastly mixed plastics e.g. some electrical or electronic wastes and automotive residues of the shredder. The general principle of recovery of materials can be persuading by utilizing feedstock recycling or chemical recycling technology however they are more expensive than mechanical recycling and less energetically conducive as the depolymerization of polymer is required and then repolymerisation. Due to the low cost of petrochemicals, this has prerequisite very conspicuous subsidies in contrary to the cost of plants and high cost to chemically recyclable polymers. Energy recovery of plastic waste can be employed to minimize the volumes of the landfill but does not minimize the stipulation of fossil fuels (Sharma et al., 2021a). Nevertheless, nowadays the intrigue regarding resource and energy recovery from waste has emerged out significantly and considerable investigations about the utilization of thermal plasmas in the treatment of plastic waste have been propounded by researchers.

Areeprasert et al elucidated the highest recovery of energy obtained from LDPE pyrolysis in Bangkok when municipal waste is taken into consideration in which the highest yield of oil was evaluated by 60% of LDPE (Areeprasert et al., 2017). Results also evinced that pyrolysis oil stated a range of raw materials produced various kinds of substances such as alkenes and alkanes. Chatterjee and his team worked on a non-incineration thermal process or thermal plasma which facilitates the complete decomposition of plastic waste into syngas at extremely high temperatures. Guddeti et al employed an inductivity coupled technology of plasma for polyethylene decomposition (Guddeti et al., 2000). Arafat and co-workers investigated the potential of energy recovery by implying municipal solid waste treatment and assess their environmental effects (Arafat et al., 2015). Few researchers employed a direct strategy of combustion i.e. incineration technique in which the transformation of feedstock directly into the energy takes place. Water vapor and carbon dioxide are the major constituents emitted via the incineration process of municipal solid waste. The important strategies to convert plastic wastes into energy recovery are gasification and biomethanation. Gasification is a swift way for the conversion of plastic waste into energy has wider feedstock, syngas, the end product is conventionally unusable; and bio methanation gives ready to utilized fuel-biogas.

3.5. Concoction of value-added products

The complexity and severity of plastic waste challenge purport that conventional methods for reusing and recycling polymers are desperately entailed. Kankermayer et al worked on the recycling of polyacetals assisted by a combination of biomass-derived diols and catalytic processing of plastic waste. Ordinarily, polyacetals react with either recycled glycols or biomass-derived to give some chemical products like 1, 3-dioxane, 1, 3-dioxolane, and 1, 3–dioxepane. The aforementioned value-added products can be utilized for applications in pharmaceutical intermediates, fuel additives, solvents, and novel monomeric materials for polymerization reactions (Beydoun and Klankermayer, 2020). An efficient solution is to employ plastic waste feedstock for the generation of H2. Reisner et al examined the conversion of PET bottle waste into H2 which is called a visible light-driven demonstration of noble metal-free photoreforming of plastic (Uekert et al., 2018). For utilization in chemical, agricultural and pharmaceutical industries, over 50 million tons of H2 is produced around the globe. It is also served as a potential renewable energy carrier. Nevertheless, 96% of worldwide H2 supply is generated through fossil fuels steam reforming (Cai et al., 2018).

Plastic waste pyrolysis can replace non-renewable processes (Iulianelli et al., 2016). Abnisa and co-workers reported the utilization of non-recycled plastic waste for potential energy recovery employing pyrolysis at 500 °C in a fixed bed reactor with 200 ml/min of nitrogen flow for 30 min (Anuar Sharuddin et al., 2017). This can be processed after eliminating PET and PVA before pyrolysis. The efficiency of the product can be enhanced by using PS which also minimizes the formation of gas and tar. The most populated country after China is India with the scenario of plastic waste management primarily based on landfills which are gradually moving towards efficient waste to energy applications of feedstock's. Ramamurthy et al investigated the transformation of plastic waste into value-added products like xylene and benzene by employing hydroprocessing in a liquid stream of hydrocarbons (Papari et al., 2021).